13

EAGLE BOOM

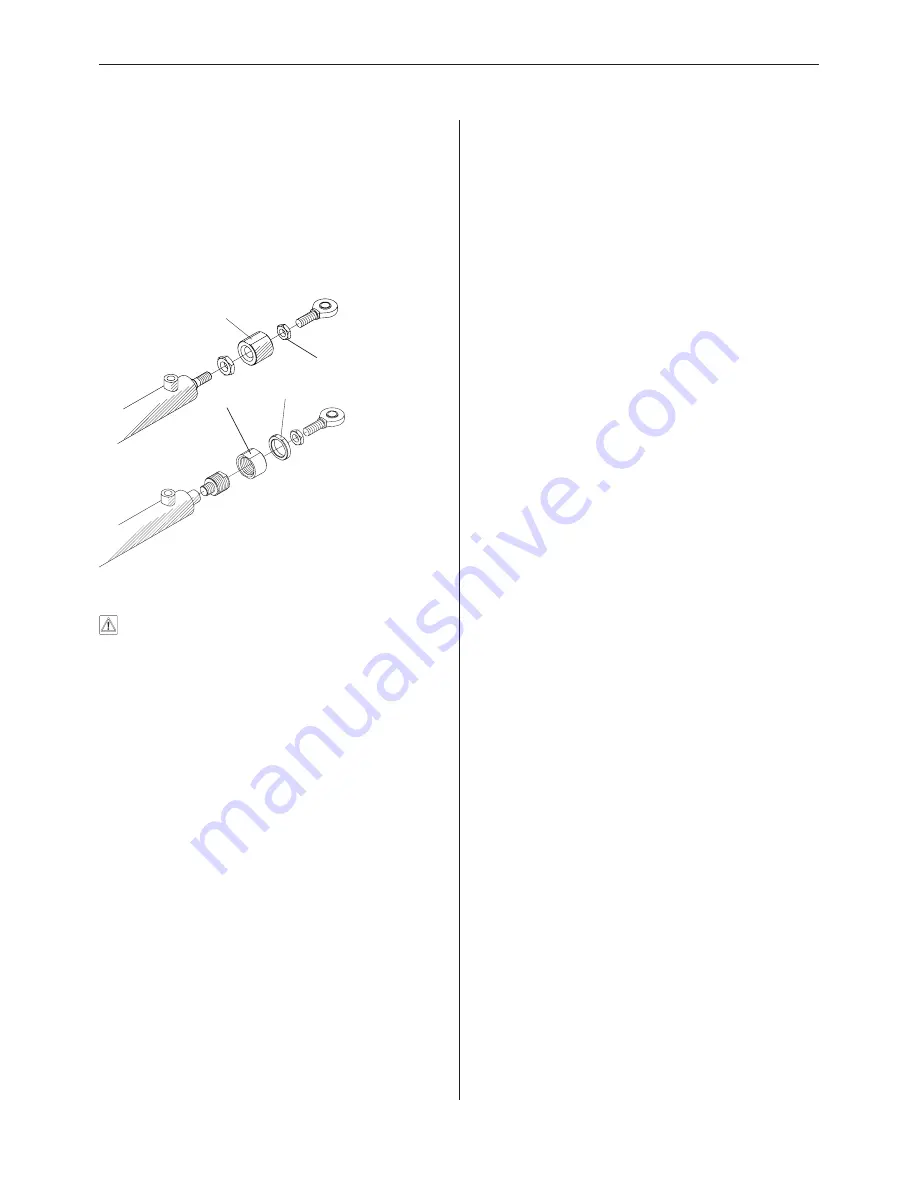

3 If the boom rests too far in on the transport support,

loosen the lock nut (B Fig 19) and adjust the collar

(A Fig 19) in towards the cylinder housing.

4 If the boom rests too far out on the transport support,

the collar (A Fig 19) has to go out from the cylinder

housing.

5 Secure the lock nut (B Fig 19).

6 Pressurise the cylinder to see if the boom is properly

adjusted. If not, repeat the above procedure until it is

correctly adjusted.

Fig 19

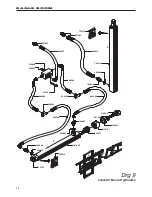

Adjusting rear cable

WARNING! Rear cable can snap and injure you or

someone else if tensioned when the boom is

unfolded. Always adjust the front cable first with

the boom unfolded and the rear cable last with the

boom folded in the transport position.

1 Raise the boom to its highest position. Fold the

boom to the transport position with the tilt cylinders (if

fitted) fully extended. Make sure fold cylinders are

pressurised and that the boom is folded all the way

in.

NOTE! If you have a YZ model, shut the fold

switch off.

2 Shut the tractor off.

3 Loosen the lock nuts on the turnbuckle. Adjust

(tighten) the turnbuckle so that the outer wing section

contacts the boom transport stop bracket. Tighten

the turnbuckle another 4 complete turns (24-28 boom

- tighten the turnbuckle 3 turns only) and re-tighten

the lock nuts.

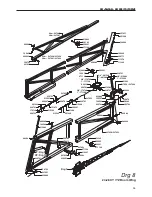

Adjusting centre frame cables

IMPORTANT! Never attempt to adjust the centre

frame cables without having the boom folded all

the way into the transport position!

Centre frame cables work together to keep the centre

frame square to the gantry, while folding boom in for

transport or when spraying with one side raised and

folded.

1 Fold the boom into the transport position.

2 Shut the tractor off.

3 Check that the tilt cylinders (if fitted) are completely

retracted. Adjust if necessary.

4 Loosen the lock nuts.

IMPORTANT! Alternate from side-to-side while

making adjustments. Adjust one cable a small

amount, and then the other - to equalize cable

tension and maintain a level centre frame.

5

Properly adjusted cables will be very tight and only

deflect a small amount (fractions of a centimetre)

when pulled on by hand.

6

Tighten the lock nuts.

7

Unfold the boom to operating (spraying) position.

8

Fold the boom and check that the centre frame

remains square to gantry.

Occasional maintenance

Make it a regular habit to inspect the boom for need of

occasional maintenance.

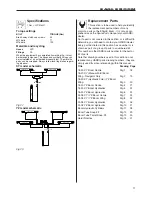

Nozzle filters

Each nozzle assembly is equipped with a 100 mesh

filter screen as standard on units equipped with yellow

Color Tips. A properly maintained suction filter and self

cleaning Filter will eliminate blocking the screens and

nozzles.

NOZZLE

SUCTION

SELF-CLEANING

NOZZLE

SIZE

FILTER

FILTER

SCREEN

Lilac (08)

50

100*

100*

Brown (10)

Yellow (12)

Orange (14)

Red (16)

50*

80

80

White (18)

Green (20)

30

50

50

& Larger

*Standard mesh

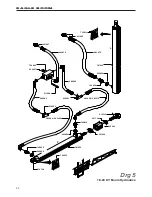

Tubes and fittings

Poor seals are usually caused by:

•

Missing O-rings or gaskets

•

Damaged or incorrectly seated O-rings

•

Dry or deformed O-rings or gaskets

•

Foreign materials

Therefore, in case of leaks, do not over-tighten. Disas-

semble, check condition and position of O-ring or

gasket, clean, lubricate and reassemble.

For radial connections, only hand tighten them.

The O-rings need to be lubricated all the way around

before fitting on to the nozzle tube.

HARDI recommends using a vegetable

based oil to prolong the life of the O-ring.

24-28 m

18-20 m

A

A

A = Collar

B = Lock Nut

B

B

Summary of Contents for Eagle Boom

Page 1: ...EAGLE BOOM Operator s Manual 67020304 AU 05 02 ...

Page 21: ...21 EAGLE BOOM ...

Page 23: ...23 EAGLE BOOM ...

Page 27: ...27 EAGLE BOOM ...

Page 28: ...28 EAGLE BOOM ...

Page 29: ...29 EAGLE BOOM ...

Page 30: ...30 EAGLE BOOM ...

Page 31: ...31 EAGLE BOOM ...