6

EAGLE BOOM

Connection

The EAGLE boom requires:

• 1 single acting hydraulic outlet (All models)

•

1 double acting hydraulic outlet (All except XY

(Manual Fold) models)

•

1 12 volt power supply (YZ models only)

Connecting hydraulics

1 Attach the heavier (

3

/

8

”) hydraulic hose to the trac-

tor’s single acting outlet.

2 Attach the smaller (

1

/

4

”) hydraulic hoses to the

tractor’s double acting outlet.

IMPORTANT! Ensure hydraulic lines have not

been damaged during shipping.

IMPORTANT! Be sure to hook up hydraulic lines

properly!

WARNING! Improper hook-up can cause danger-

ous boom movements and/or damage to the

sprayer hydraulics.

WARNING! Ensure all connections are tight before

applying pressure. Search for leaks with a piece of

cardboard - not your hands!

WARNING! Escaping hydraulic fluid under pres-

sure can penetrate the skin causing serious injury.

Avoid this hazard by relieving pressure before

disconnecting hydraulic lines.

WARNING! Always shut tractor off when connect-

ing, servicing or adjusting boom.

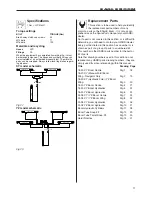

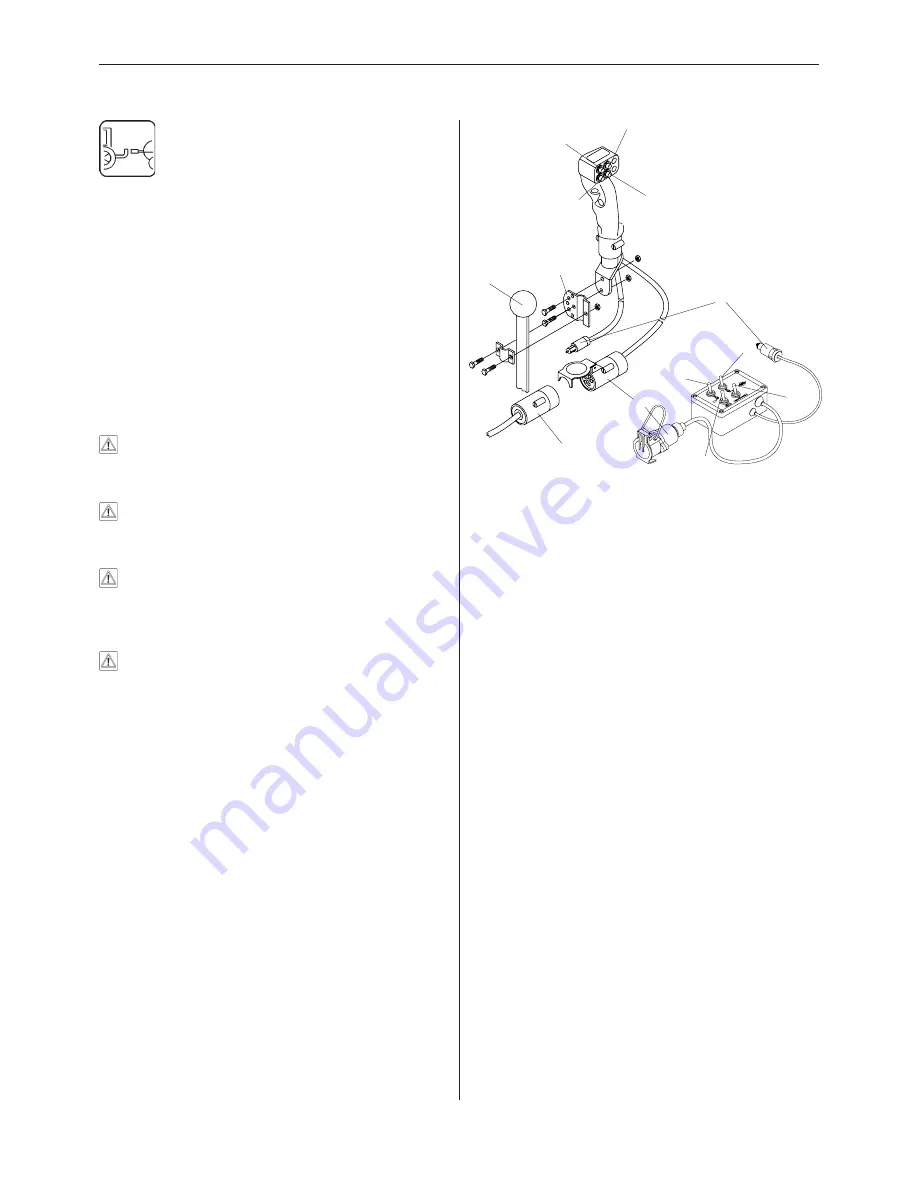

Connecting electric controls

1 Attach the handle to the hydraulic lever that operates

the double acting outlet you intend to use. The

universal mounting bracket (E Fig 2) is very flexible

and a number of different mounting positions can be

used.

If required as an alternative to the handle, mount the

switch box in a suitable location in the tractor cab.

2 Connect the handle power plug or switch box power

plug (F Fig 2) to the tractors 12 volt power system.

Try to connect the handle or switch box as close as

possible to the battery for a better power supply.

HARDI recommends using electric distribution box

#817925 to insure a good power supply to various 12

volt attachments.

NOTE! Check with your HARDI dealer or your

tractor’s operator’s manual for the best location to

hook up the 12 volt system.

Polarity

(+)

(-)

Wire Colour

Brown

Blue

3 Connect the electric boom control plug (H Fig 2) to

the handle control plug or switch box control plug (G

Fig 2).

Fig 2

A

B

C

D

E

F

G

H

I

A = Left Fold Switch

B = Right Fold Switch

C = Left Tilt Switch

D = Right Tilt Switch

E = Universal Mounting Bracket

F = Handle Power Plug / Switch Box Power Plug

G = Handle Power Plug / Switch Box Control Plug

H = Boom Control Plug

I = Tractor Hydraulic Lever

A

B

D

C

HANDLE

SWITCH BOX

Summary of Contents for Eagle Boom

Page 1: ...EAGLE BOOM Operator s Manual 67020304 AU 05 02 ...

Page 21: ...21 EAGLE BOOM ...

Page 23: ...23 EAGLE BOOM ...

Page 27: ...27 EAGLE BOOM ...

Page 28: ...28 EAGLE BOOM ...

Page 29: ...29 EAGLE BOOM ...

Page 30: ...30 EAGLE BOOM ...

Page 31: ...31 EAGLE BOOM ...