24

HARDI

®

GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

8.0 STORAGE

When the spraying season is over, you should devote some extra time

to the sprayer. If chemical residues are left over in the sprayer for long

periods, it can reduce the life of the individual components. To

preserve the sprayer and protect the components, carry out the

following off-season storage program:

1. Clean the sprayer completely - inside and outside - as described in

Section 7.1 “Cleaning The Sprayer“. Make sure that all valves,

hoses and auxiliary equipment have been cleaned with detergent

and flushed with clean water afterwards, so no chemical residues

are left in the sprayer.

2. Replace any damaged seals and repair any leaks.

3. Empty the sprayer completely and let the pump work for a few

minutes. Operate all valves and handles to drain as much water out

of the spraying circuit as possible. Let the pump run until air is

coming out of all nozzles.

4. Fill the tank with 3 - 5 gallons of an ethylene glycol base anti-freeze

mixture at the ratio for the desired temperature protection. Run the

pump and circulate the anti-freeze through the distribution valves

and boom lines. Spray the handgun into the tank until anti-freeze

sprays out to make sure the line is full of anti-freeze.

NOTE:

Never use diesel fuel in a sprayer.

5. When the sprayer is dry, remove rust from any scratches in the paint

and touch up the paint.

6. Lubricate the boom (Section 7.2).

7. Remove the glycerine-filled pressure gauge and store in a vertical

position in a frost-free environment.

8. To protect against dust, the sprayer can be covered by a tarpaulin.

Ensure ventilation to prevent condensation.

8.1 Preparation After Storage

After a storage period, the sprayer should be prepared for the next

season in the following way:

1. Remove the cover (If fitted).

2. Fit the pressure gauge again. Seal with Teflon tape.

3. Connect the sprayer to the tow vehicle (Section 3.0).

4. Empty the remaining antifreeze into an approved container.

5. Rinse the entire liquid circuit on the sprayer with clean water. Don’t

forget to flush the boom and handgun lines also.

6. Fill with clean water and check all functions (Section 4.0).

Summary of Contents for ES 50

Page 1: ...ESTATE SPRAYERS GAS ENGINE Operator s Manual 67301103 6 01 ...

Page 2: ......

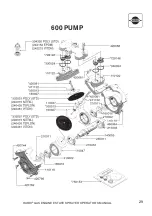

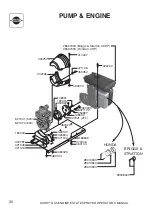

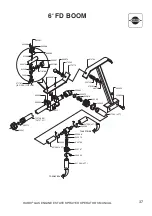

Page 30: ...28 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 11 0 PARTS DRAWINGS 500 PUMP ...

Page 31: ...29 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 600 PUMP ...

Page 33: ...31 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL PUMP FITTINGS ...

Page 34: ...32 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ET MANUAL CONTROL ...

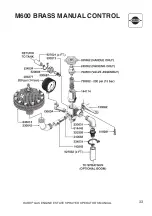

Page 35: ...33 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL M600 BRASS MANUAL CONTROL ...

Page 36: ...34 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ES 50 80 TANK ...

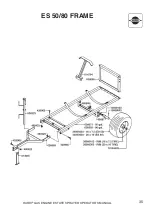

Page 37: ...35 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL ES 50 80 FRAME ...

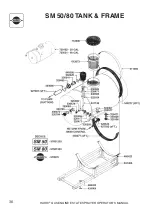

Page 38: ...36 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL SM 50 80 TANK FRAME ...

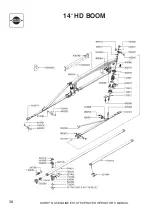

Page 40: ...38 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 14 HD BOOM ...

Page 41: ...39 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL SPRAYGUN ...

Page 42: ...40 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL HOSE REEL ...

Page 45: ...43 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL 13 0 NOTES ...

Page 46: ...44 HARDI GAS ENGINE ESTATE SPRAYER OPERATOR S MANUAL NOTES ...

Page 47: ......