4

Functions include correct area with closure of up to 8 spray boom

sections, alarm functions for dosage and minimum tank contents and

possibility for audio/visual alarm.

The transducers utilised are chosen for long service life and good

signal quality. Speed, area switch and revolutions transducer is the

same component. The flow transducer has a diode built into the

housing to aid servicing. As the rotor turns, the diode will flash thereby

indicating it functions.

The system has a non-volatile memory with no battery which simplifies

storage. All parameters in the menus are saved in the display’s

memory and are not lost when the power is disconnected.

The materials and electronics for the components have been devel-

oped to last many years under agricultural conditions.

Options include a 4-20 mA transducer (e.g. pressure), revolutions

transducer, area meter transducer and switch box for boom sections

when used with BK or BK/EC control unit (only for HM 1500).

Fitting the system

Please note the configuration and connections for your system.

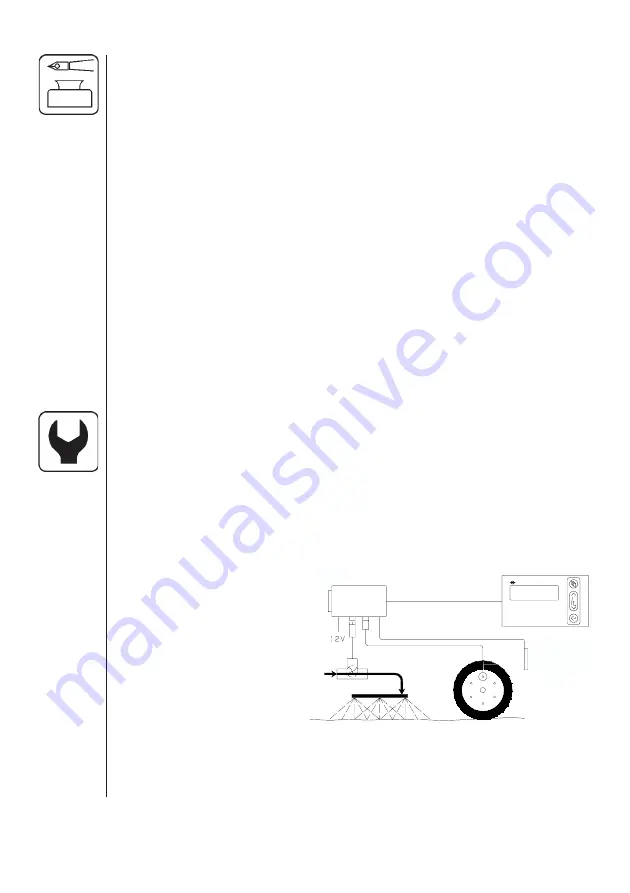

HM 1500 Monitor with manual control unit (BK, BK/EC)

The active boom width is always the total boom width.

The system can not automatically calculate correctly when one or more

boom sections are turned off.

1.

HM 1500 display

2.

Display connector cable

3.

Scanbox (fuse inside)

4.

On/off switch

5.

Speed transducer

6.

Flow transducer

7.

To 12 Volt power supply

8.

Switch box connector

cable (not used)

1.

2.

3.

4.

5.

6.

7.

8.