5 - Operation

39

Filling through tank lid

Water is filled into the tank by removing the tank lid located at the top of the tank on the sprayer’s right side. The tank lid is

accessible from the optional footboard. It is recommended to use as clean water as possible for spraying purposes. Always

fill water through the strainer basket to prevent foreign particles from entering the tank. An overhead tank can be used in

order to obtain high filling capacity.

±

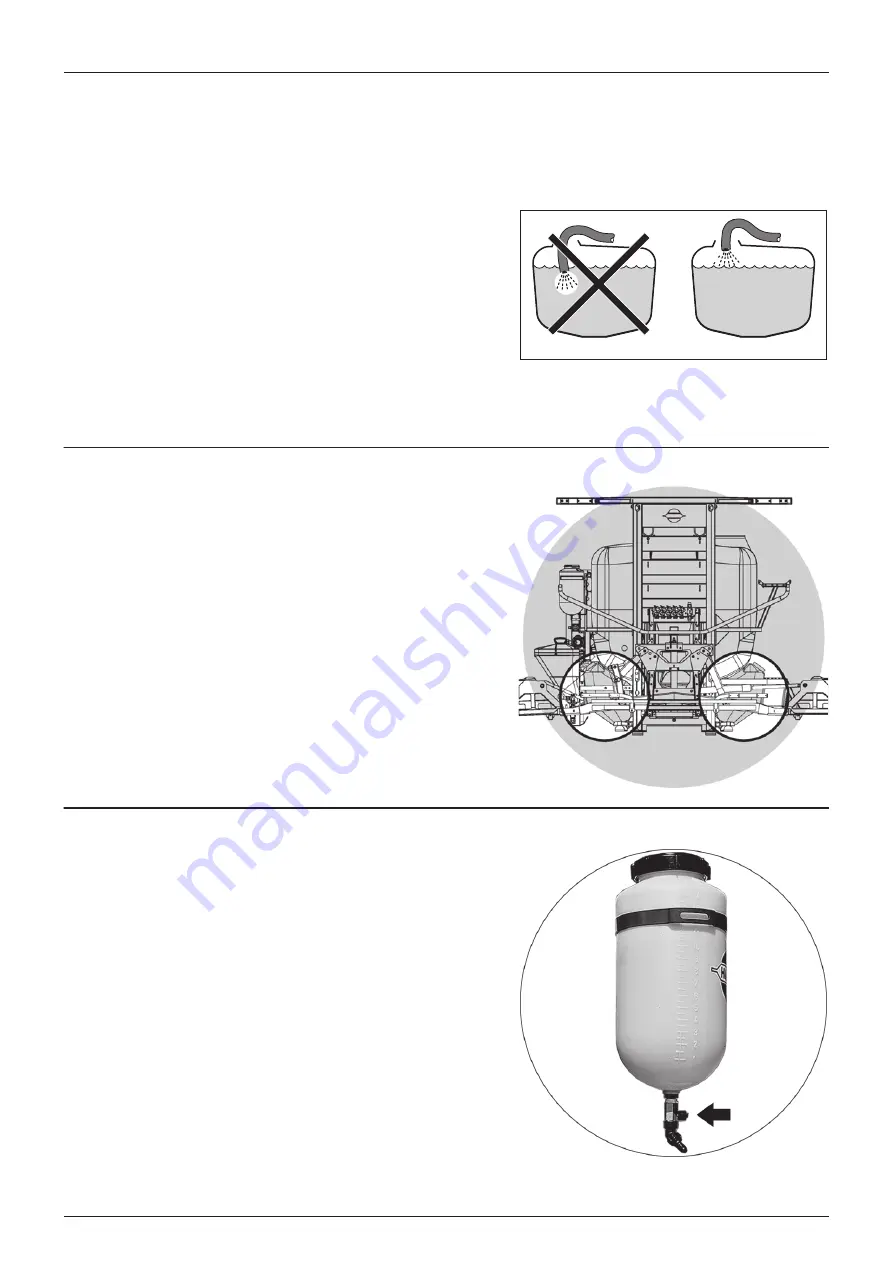

WARNING! Do not let the filling hose enter the tank. Keep it

outside the tank, pointing towards the filling hole. If the hose is

led into the tank and the water pressure drops at the water

supply plant, chemicals may be syphoned back and contaminate

the water supply lines, plant and well.

±

WARNING! The water supply line should be provided with a check

valve as additional safety precaution. Follow local legislation in

force at any time.

±

WARNING! The water supply should be provided with a meter to avoid spillage by over-filling. Follow local legislation

in force at any time.

Filling of rinsing tanks (optional)

If one or two rinsing tanks are fitted to the the sprayer, they arefilled via

thelid on the top of the tanks:

1.

Remove the fillerlid of the tank to be filled.

2.

Fill water into the tank. Keep an eye on the tank opening in order

not to overfill the tank.

3.

Stop filling and replace the lid.

Capacity: approx. 80 litres each.

μ

ATTENTION! Only fill rinsing tank with clean water! To avoid algae

developing in the rinsing tank always drain the rinsing tank if the

sprayer is not in use for a longer period of time.

Filling of clean water tank (optional)

To fill the clean water tank:

1.

Remove the tank lid

2.

Fill with clean water

3.

Reposition the tank lid.

For use of water:

•

Turn the ball valve lever to open (arrowed).

The water from this tank is for hand washing, cleaning of clogged

nozzles etc. Only fill the clean water tank with clean water from the well.

±

WARNING! Although the clean water tank is only filled with clean

water, this water must NOT be used for drinking.

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...