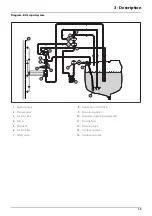

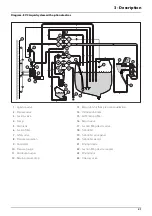

3 - Description

16

(E) External Filling Device valve (optional)

The valve is used when filling from an external tank or reservoir.

Activating valve starts/stops the filling process. Note that the suction valve must be closed for maximum filling capacity.

μ

ATTENTION! If a valve is too tight to operate - or to loose (= liquid leakage) - the valve needs to be serviced. Please see

the section ‘Maintenance’ for further information.

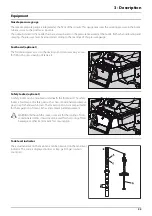

Control unit

The sprayer is equipped with either a BK control unit or an EVC control unit.

The system is based on EVC - Electrical Valve Control. The ON/OFF is linked to the section valves, which is results in a very

quick response to ON/OFF. The operating unit is constructed of modules and is electrically controlled via a remote control

box.

With HARDI-MATIC that ensures a constant liquid volume per hectare (l/ha) at varying forward speed within the same gear

when the number of P.T.O. revolutions are between 300-600 r/min.

BK control unit

The BK control unit consists of; pressure agitator valve, safety valve, main ON/OFF valve, pressure filter with pressure gauge,

distribution valves with pressure equalization and HARDI-MATIC pressure control valve.

EVC control unit

EVC - Electrical Valve Control. The ON/OFF is linked to the section valves, which results in a very quick response to ON/OFF.

The operating unit is of modular design and is electrically controlled via a remote control box. The unit has a built-in HARDI

MATIC.

Clean water tank (optional)

The water in this tank is for hand washing, cleaning of clogged nozzles

etc. Only fill this tank with clean water from the well.

The clean water tank is placed on the sprayer’s left side, right behind the

MANIFOLD valves.

Capacity: approx. 15 litres (3.3 Imp. gal).

±

WARNING! Although the clean water tank is only filled with clean

water, this water must NOT be used for drinking.

Suction from external tank

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...