4 - Sprayer setup

32

Liquid system

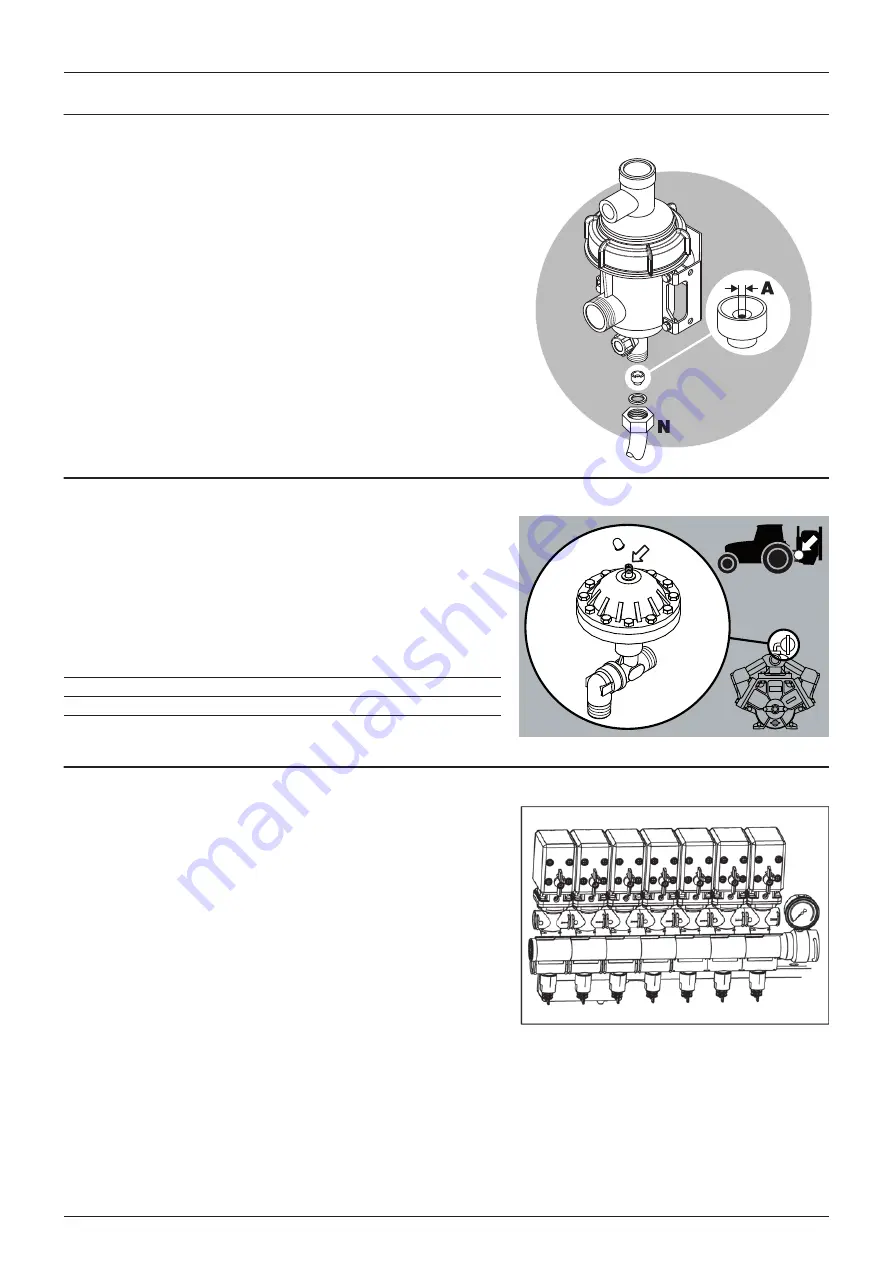

Self-cleaning filter - Choice of restrictor

It is important to have a large flow through the filter. This is achieved by

choosing the restrictor size in relation to the liquid consumption of the

spray boom. 4 restrictors are supplied. Use the green one with largest

orifice (A) first.

Remove the hose (N) from the filter. Be careful not to loose the seal. Place

the restrictor in the hose and mount the hose again.

If the required working pressure cannot be obtained, the restrictor is too

large. Choose a smaller restrictor. Start with a black one, then a white and

finally a red one.

When cleaning the filter, remove hose (N) and the hose at the safety

valve and check that there are no residues.

Standard filter size is 80 mesh. Filters of 50 and 100 mesh are available

and can be changed by opening the filter top. Check condition of O-

rings before reassembly and replace if damaged.

Pulsation damper (if fitted)

The air pressure in the pulsation damper is factory preset at 2 bar to

cover spray working pressures between 3 and 15 bar.

When using spray pressures outside this range, the air pressure should

be adjusted as shown in the diagram. The diagram is embossed on the

damper.

Adjustment of EVC operating unit

Adjust the EVC operating unit before spraying, using clean water

(without chemicals).

1.

Choose the correct nozzle for the spray job by turning the TRIPLET

nozzle bodies. Make sure that all nozzles are of the same type and

capacity. See the “Spray Technique” book.

2.

Set the main ON/OFF switch to ON at the spray control unit.

3.

Turn all distribution valve switches ON at the spray control unit.

4.

Press down the pressure regulation switch at the spray control unit

until the emergency handle on the valve stops rotating (minimum

pressure).

5.

Put the tractor in neutral and adjust the P.T.O. and thereby the

number of revolutions of the pump corresponding to the intended travelling speed. Remember to keep the number

of revolutions of the P.T.O. between 300-600 rpm (pump 540 r/min) or 650-1100 rpm (pump 1000 r/min).

6.

Press up the pressure regulation switch at the spray control unit until the required spray pressure is shown on the

pressure gauge.

ADJUSTMENT OF PRESSURE EQUALIZATION:

7.

Close the first section valve on the spray control unit.

Spray Pressure (Bar)

Damper pressure (Bar)

1.5 - 3

0 - 1

3 - 15

1 - 3

15 - 25

3 - 4

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...