5 - Operation

45

Agitation before resuming a spray job

If a spray job has been interrupted for a while, severe sedimentation may

occur depending on the chemicals being used. Before resuming the

spray job, it might be necessary to agitate sedimented material.

1.

Turn the handle at the suction valve towards “Suction from main

tank”. Turn the pressure valve to closed position and turn the

Agitation valve towards “Agitation” (If BK operating unit: turn

agitation on at lever on BK operating unit). Other valves closed.

2.

Engage the pump and set P.T.O. speed at 540 r/min.

3.

Agitation has started and should be continued for at least 10

minutes.

The spray job can now be resumed. Turn pressure valve towards

“Spraying” and start spraying.

Parking the sprayer

To avoid spot contamination the sprayer should always be parked at either the washing/filling place or under roof. This avoid

rainfall to flush down chemcical residues from the sprayer's surfaces.

•

Parking at the washing/filling location will retain residues.

•

Always park the machine out of reach of children, animals or unauthorised persons.

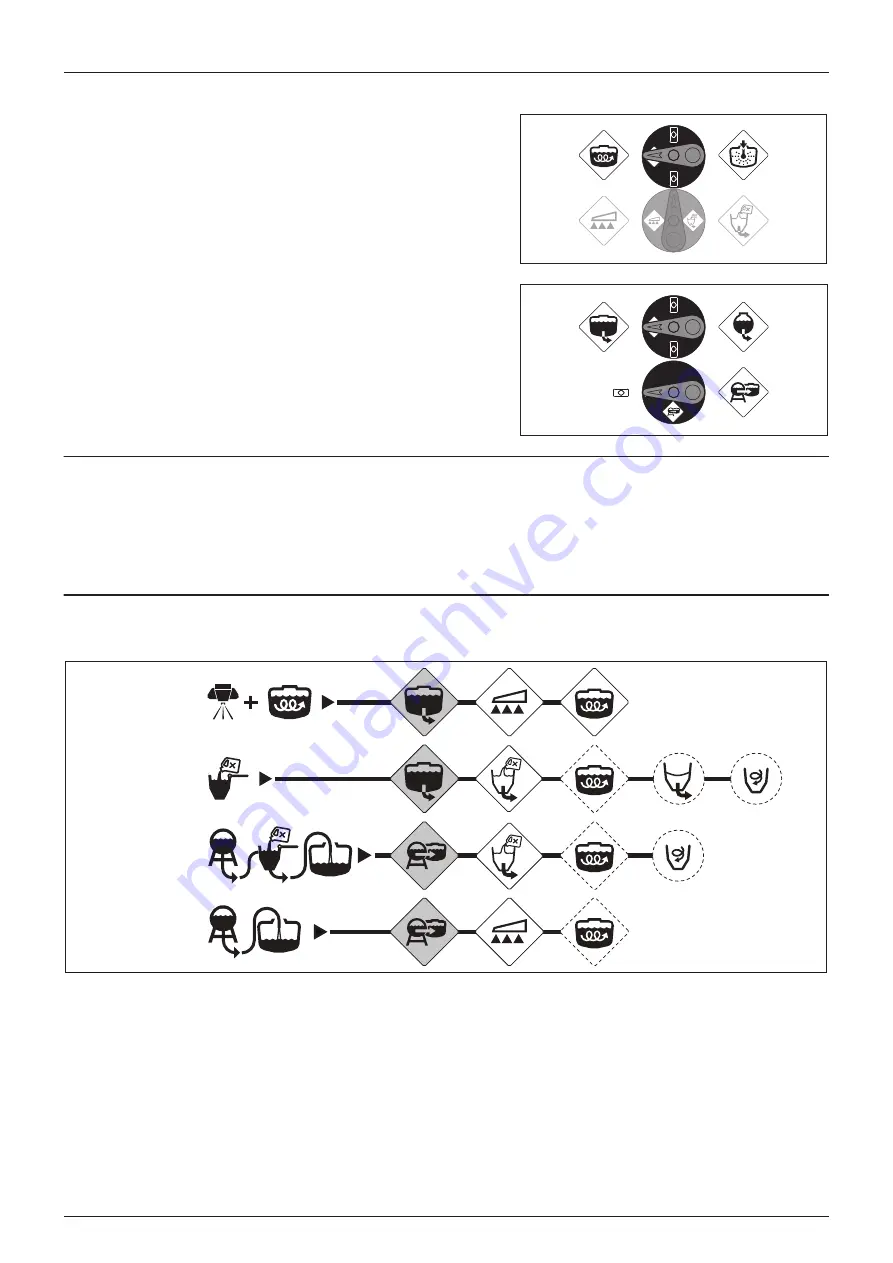

Quick reference - Operation

In the following diagrams handle positions for different options are described.

μ

ATTENTION! When setting the handles in situation 4, the regulation valve also needs to be closed, for the external

filling to work properly.

1

2

3

4

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...