6 - Maintenance

57

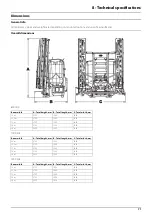

Cone check/renewal for EVC distribution valve

Periodically check the distribution valves for proper sealing. Do this by

running the sprayer with clean water and open all distribution valves.

Cautiously remove the clip (A) and pull out the hose (B) for the return

line. When the housing is drained, there should be no liquid flow

through the return line.

If there is any leakage, the valve cone (E) must be changed.

1.

Remove the clip (C)

2.

Lift the motor housing off the valve housing.

3.

Unscrew the screw (D) and replace the valve cone (E).

4.

Reassemble in reverse order.

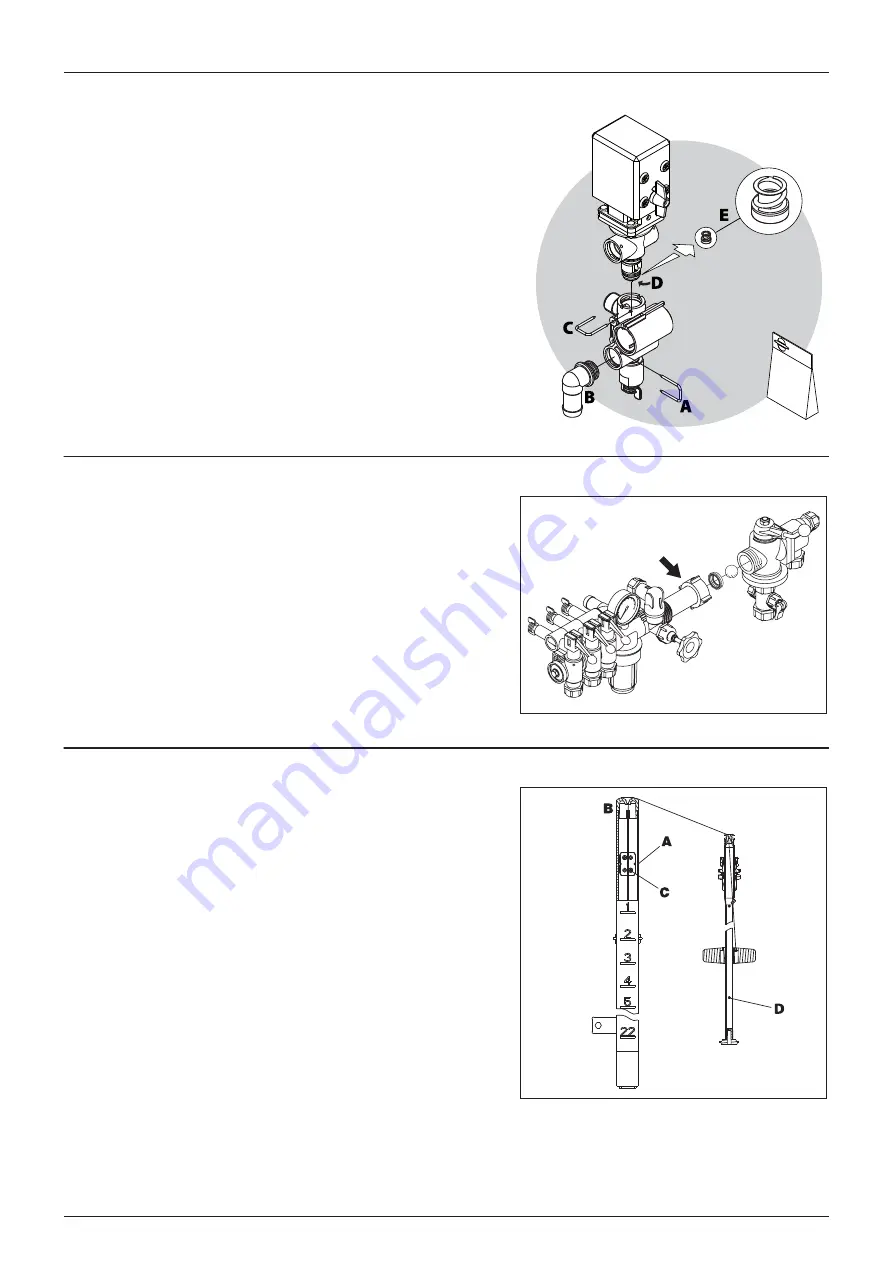

Changing the ball seat in BK operating unit

If the main ON/OFF valve does not seal properly (dripping nozzles when

main ON/OFF valve is closed), the ball and seat should be checked.

Remove the 2 bolts fixing the main ON/OFF-pressure valve unit to the

bracket, unscrew the union nut (arrow) and pull the valve away from the

distribution valves. Check the ball for sharp edges and scratches, and

check the ball seat for cracks and wear - replace if necessary.

Level indicator adjustment

The level indicator reading should be checked regularly. When the tank

is empty, the float should lie on the stop pin (D), of the rod, and the O-

ring on the indicator should be positioned at the top position line (A).

If any deviation is found, pull out the plug (B), loosen screws (C), and

adjust the length of the cord.

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...