6 - Maintenance

59

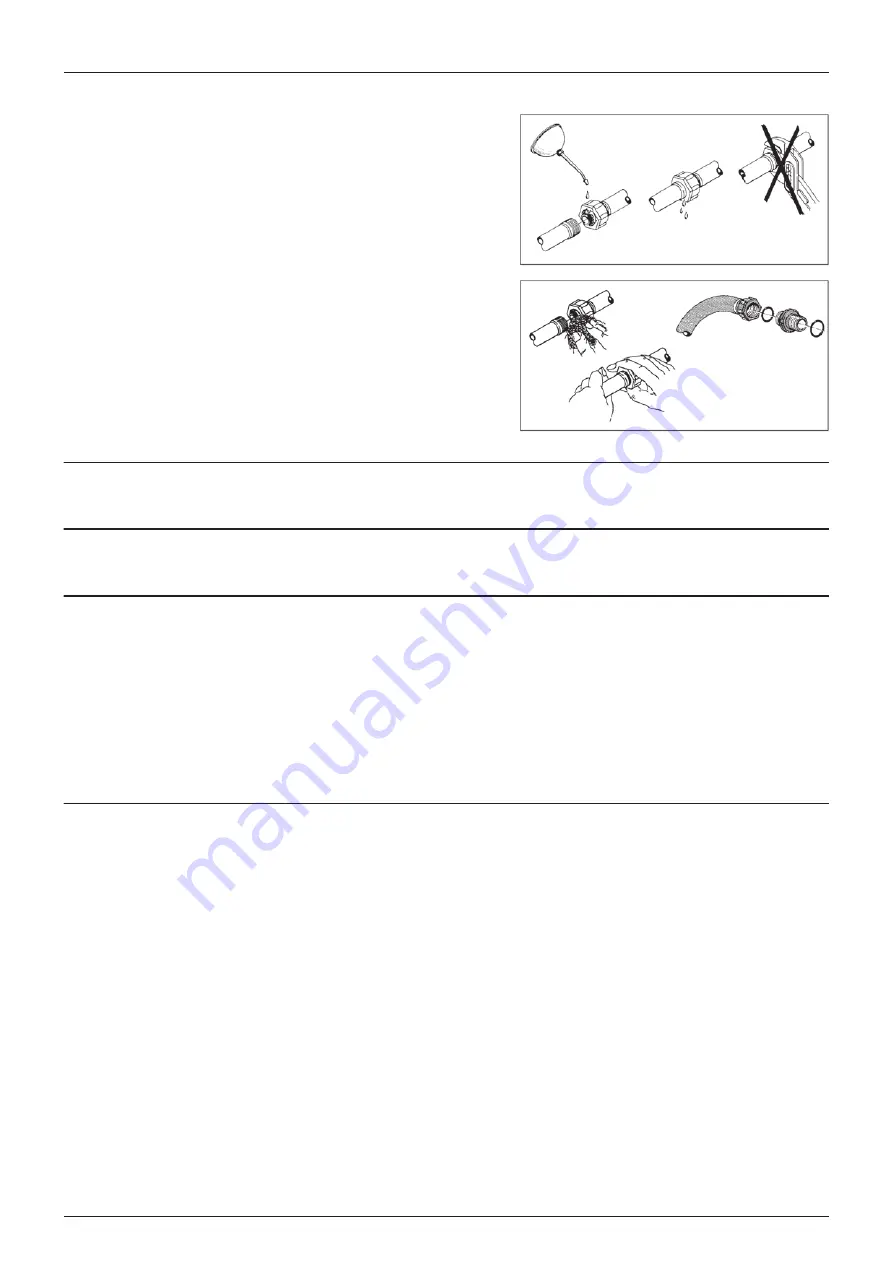

Nozzle tubes and fittings

Poor seals are usually caused by:

•

Missing O-rings or gaskets

•

Damaged or incorrectly seated O-rings

•

Dry or deformed O-rings or gaskets

•

Foreign bodies

In case of leaks:

DO NOT overtighten. Disassemble, check condition and position of O-

ring or gasket. Clean, lubricate and reassemble.

The O-ring must be lubricated ALL THE WAY ROUND before fitting on to

the nozzle tube. Use non-mineral lubricant.

For AXIAL connections, a little mechanical leverage may be used. For

RADIAL connections only tighten by hand.

Shield renewal on transmission shaft

See the manufacturer’s instruction book.

Replacement of transmission shaft cross journals

See the manufacturer’s instruction book.

Change of bulbs

1.

Switch off the light.

2.

Loosen the screws on the lamp and remove the cover or lens.

3.

Remove the bulb.

4.

Fit a new bulb, refit the cover and tighten the screws.

μ

ATTENTION! If halogen bulbs are used, never touch the bulb with your fingers. Natural moisture in the skin will cause

the bulb to burn out when the light is switched on. Always use a clean cloth or tissue when handling halogen bulbs.

Safety valve activation

To make the fluid system work perfectly over time, it is good practice to regularly provoke opening of the safety valve.

€

This avoids clogging and ensures proper function of the safety valve. This is done by turning the pressure valve to an

unused function when pump is running. This is good practice for all but particularly for sprayers without optional

equipment.

Summary of Contents for MASTER PRO VHH

Page 6: ...Table of Contents 6 ...

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 50: ...5 Operation 50 ...

Page 52: ...6 Maintenance 52 Boom lubrication oiling plan Lift lubrication oiling plan ...

Page 70: ...7 Fault finding 70 ...

Page 76: ...8 Technical specifications 76 Charts Boom hydraulic Z ...

Page 78: ...8 Technical specifications 78 ...

Page 82: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...