GB 08 00 MA

Operation - liquid system

Adjustment of

Adjustment of

Adjustment of

Adjustment of

Adjustment of EV

EV

EV

EV

EVC oper

C oper

C oper

C oper

C opera

aa

a

ating unit

ting unit

ting unit

ting unit

ting unit

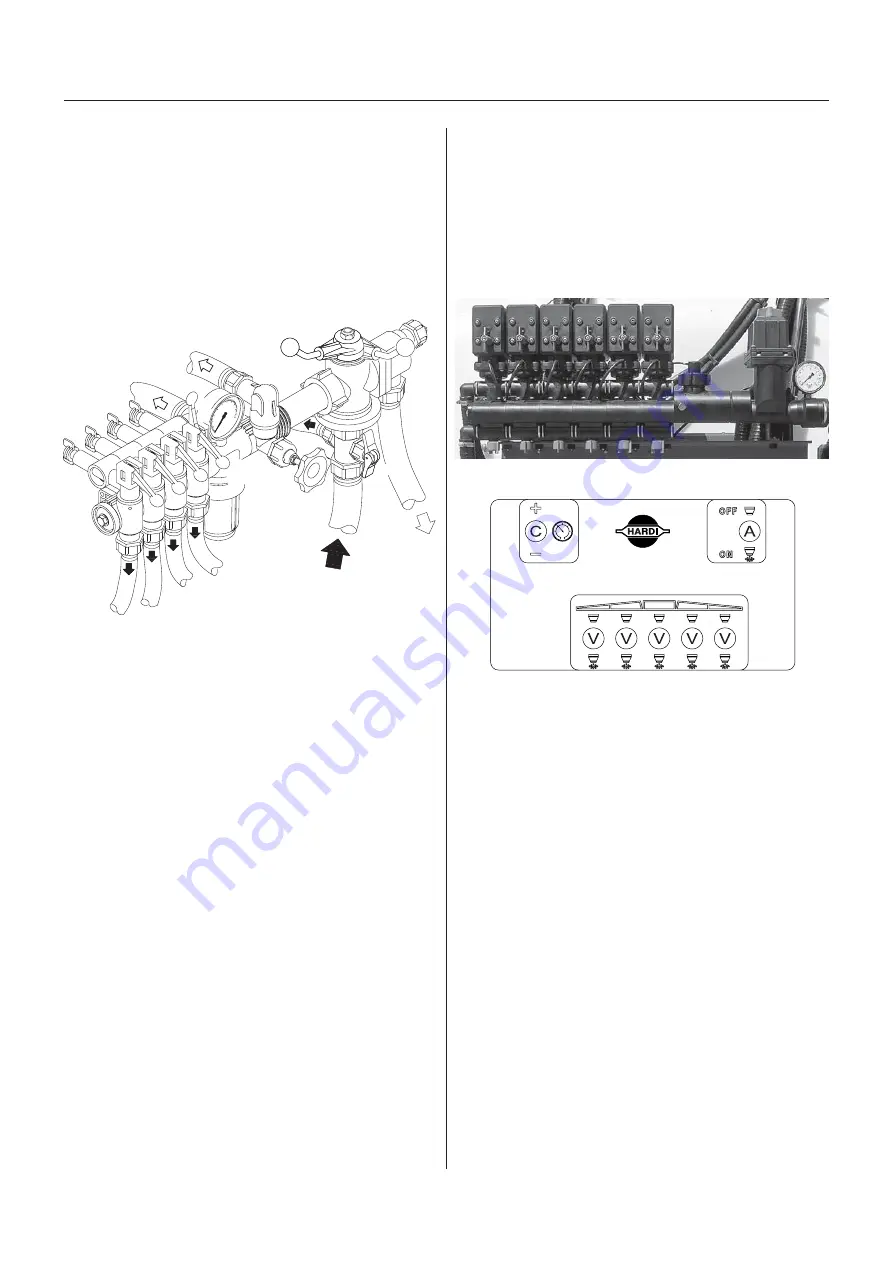

Before spraying, the EVC operating unit is adjusted

using clean water (without chemicals).

1. Choose the correct nozzle for the spray job by turning

the TRIPLET nozzle bodies. Make sure that all

nozzles are the same type and capacity. See the

“Spray Technique” book.

2. On-off switch

A

is activated against green.

3. All distribution valve switches

V

are activated against

green.

4. Pressure regulation switch

C

is activated until emer-

gency handle stops rotating (minimum pressure).

5. Put the tractor in neutral and adjust the P.T.O. and

thereby the number of revolutions of the pump

corresponding to the intended travelling speed.

Remember the number of revolutions on the P.T.O.

must be kept between 300-600 rpm (pump 540 r/min)

or 650-1100 rpm (pump 1000 r/min).

6. Pressure regulation switch

C

is activated until the

required pressure is shown on the pressure gauge.

Adjustment of pressure equalisation

1. Close the first distribution valve switch

V

.

2. Turn the adjusting screw(s) until the pressure gauge

again shows the same pressure.

3. Adjust the other sections of the distribution valve in

the same way.

2

B

A

4

B

A

5

3

1

Adjustment of

Adjustment of

Adjustment of

Adjustment of

Adjustment of the oper

the oper

the oper

the oper

the opera

aa

a

ating unit

ting unit

ting unit

ting unit

ting unit

Adjustment of

Adjustment of

Adjustment of

Adjustment of

Adjustment of BK oper

BK oper

BK oper

BK oper

BK opera

aa

a

ating unit

ting unit

ting unit

ting unit

ting unit

1. Choose the correct nozzle. Make sure that all nozzles

are the same type and capacity. See “Spray Tech-

nique” book.

2. Open or close lever

1

depending on whether pressure

agitation is required. (Remember pressure agitation

takes 5% to 10% of pump output).

3. Turn main ON/OFF handle

2

to ON position

A

.

4. Set all hand levers

3

on the distribution valve to ON

position

A

.

5. Turn the HARDI-MATIC valve

4

anti-clockwise to its

extreme position.

6. Put the tractor in neutral and adjust the P.T.O. thereby

the number of revolutions of the pump corresponding

to the intended travelling speed.

NOTE!

The P.T.O. revolutions must be kept between

300-600 r/min.

7. Adjust the HARDI-MATIC valve

4

so that the pressure

gauge indicates the recommended pressure.

ADJUSTMENT OF PRESSURE EQUALIZATION:

8. Place the first lever

3

on the distribution valve in OFF

position

B

.

9. Turn the adjusting screw

5

until the pressure gauge

again shows the same pressure.

10.Adjust the other sections of the distribution valve in

the same way.

Hereafter adjustment of pressure equalization will

only be needed if you change to nozzles of other

capacities.

11.Operating the control unit while driving:

To stop the liquid flow to the boom turn the ON/OFF

handle

2

to OFF position

B

. This returns the pump

output to the tank through the return system. The

diaphragm anti-drip valves ensure instantaneous

closing of all nozzles. To stop the liquid flow to one or

T020-0019

more boom sections, turn lever

3

of the distribution

valve to OFF position

B

for the section to be closed.

The pressure equalization ensures that the pressure

does not rise in the sections which are to remain

open.

T020-0044