GB 14 02 02 MA

Maintenance

F

FF

F

F

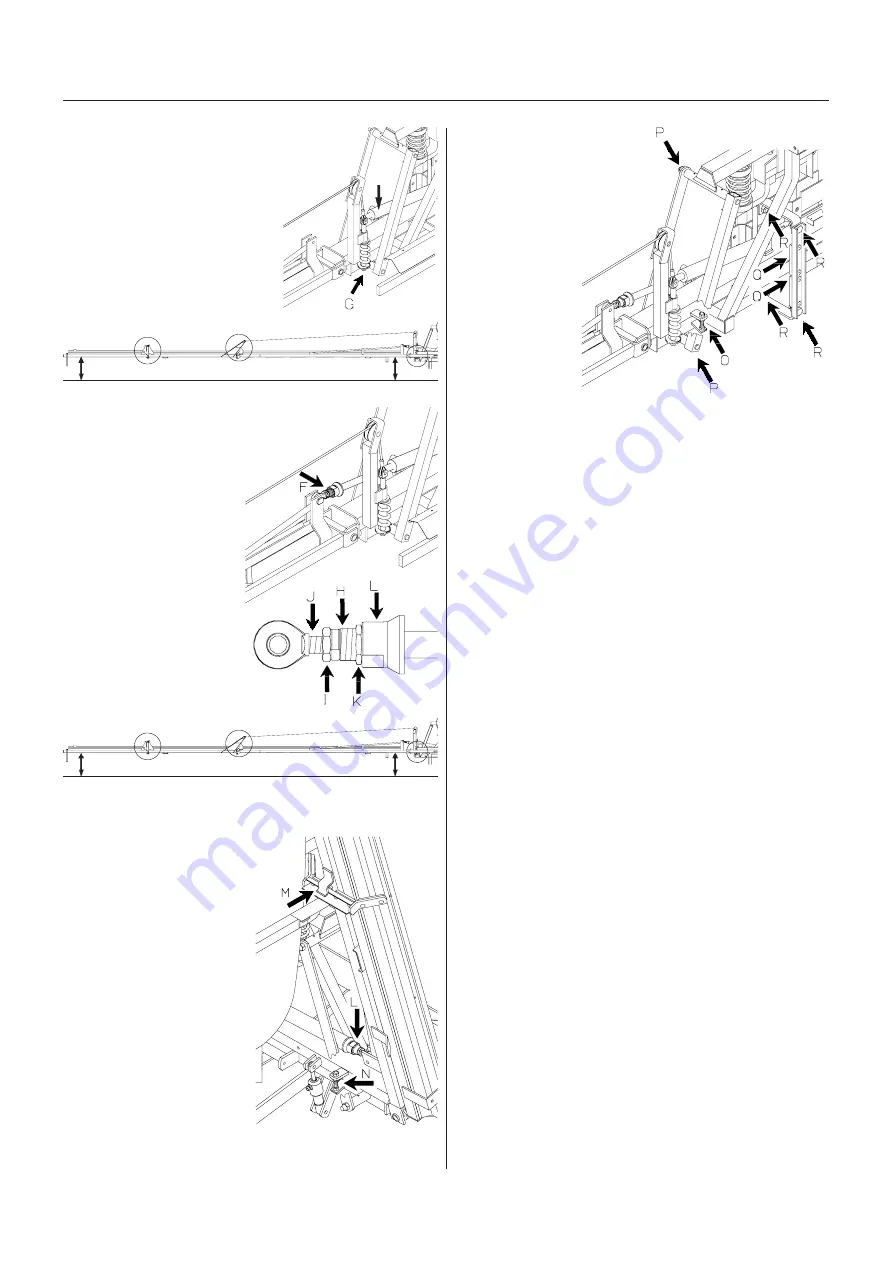

4. Wire

The wire function is to carry the boom

wings. Adjustment of the wire should be

undertaken with the boom unfolded

and the hydraulic rams

F

discon-

nected from the boom wings.

Tighten nut

G

so that the tip is

raised 12 cm for the 12 m boom

and 15 cm for the 15 m boom

from the horizontal line of the

centre section.

5. Parallel adjustment of inner section

1. Cautiously activate the hydraulic rams

F

so they are fully extended. Make

sure the extension

H

is screwed

in and tight.

2. Loosen counter nut

I

and adjust the ram eye

J

so that when connected,

the boom wings are

parallel with the centre

section. The ram must

force the boom tip down

so distance “X” is equal.

6. Adjustment for transport brackets

and air stream angle

Fold boom and lower cautiously into

transport brackets. Loosen coun-

ter nut

K

and adjust

L

so the

boom rests in the middle of

the brackets.

When the boom is lowered,

it must be firmly hooked onto

the transport bracket

M

.

Loosen counter nuts and

adjust bolt

N

so that the

boom hooks firmly into place

without exerting excessive

force on the boom wings.

Unfold the boom. Loosen

counter nut and screw bolt

O

in fully. Set air stream to

angle forward so the ram is

fully extended. Now adjust

bolt

O

up to the stop and turn furthermore ” a turn.

X + 12/15 cm

X cm

7. Trapeze suspension

For the trapeze to function it

must not be to tight. If it is to

loose the boom will yaw

(forward and back move-

ment). This results in a poor

spray distribution.

Adjust tension

P

so

the boom is not

too tight nor too

loose. Minor

adjustment in the

field may be

necessary.

Check distance

Q

.

The synthetic pads

should only just touch the centre beam. Relocate wash-

ers on each of the 4 bolts

R

if the distance is excessive.

IMPORTANT!

Check all counter nuts are tight after

adjustment.

Changing of

Changing of

Changing of

Changing of

Changing of v

v

v

v

valv

alv

alv

alv

alves and dia

es and dia

es and dia

es and dia

es and diaphr

phr

phr

phr

phra

aa

a

agms

gms

gms

gms

gms

Access to the pump is best from the rear of the sprayer.

A “

S

” shaped hook supplied with the sprayer is used to

mechanically secure the boom from lowering whilst

servicing the pump. Raise the boom with the hydraulic

boom lift and use the hook as shown.

X cm

X cm

WARNING!

Always secure

the boom before

servicing the

pump.

NOTE!

For

servicing model

361 pump, it is

best to remove

the lower anchor

bolt of the lift ram

and push the ram

over to one side.