GB 16 02 MA

Fault finding

FAULT

Operating unit not function-

ing

PROBABLE CAUSE

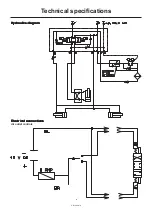

Blown fuse(s).

Wrong polarity.

Valves not closing properly.

No power.

CONTROL/REMEDY

Check mechanical function of microswitches.

Use cleaning/lubricating agent if the switch

does not operate freely.

Check motor. 450-500 milli-Amperes max.

Change motor, if over.

Brown - pos. (+). Blue - neg. (-).

Check valve seals for obstructions.

Check microswitch plate position. Loosen

screws holding plate a

1

/

2

turn.

Wrong polarity. Check that brown is pos. (+),

Blue is neg. (-).

Check print plate for dry solders or loose

connections.

Check fuse holder are tight around fuse.

EV

EV

EV

EV

EVC Oper

C Oper

C Oper

C Oper

C Opera

aa

a

ating unit

ting unit

ting unit

ting unit

ting unit

Emer

Emer

Emer

Emer

Emerg

g

g

g

genc

enc

enc

enc

ency oper

y oper

y oper

y oper

y opera

aa

a

ation of

tion of

tion of

tion of

tion of BK/EC and EC

BK/EC and EC

BK/EC and EC

BK/EC and EC

BK/EC and EC

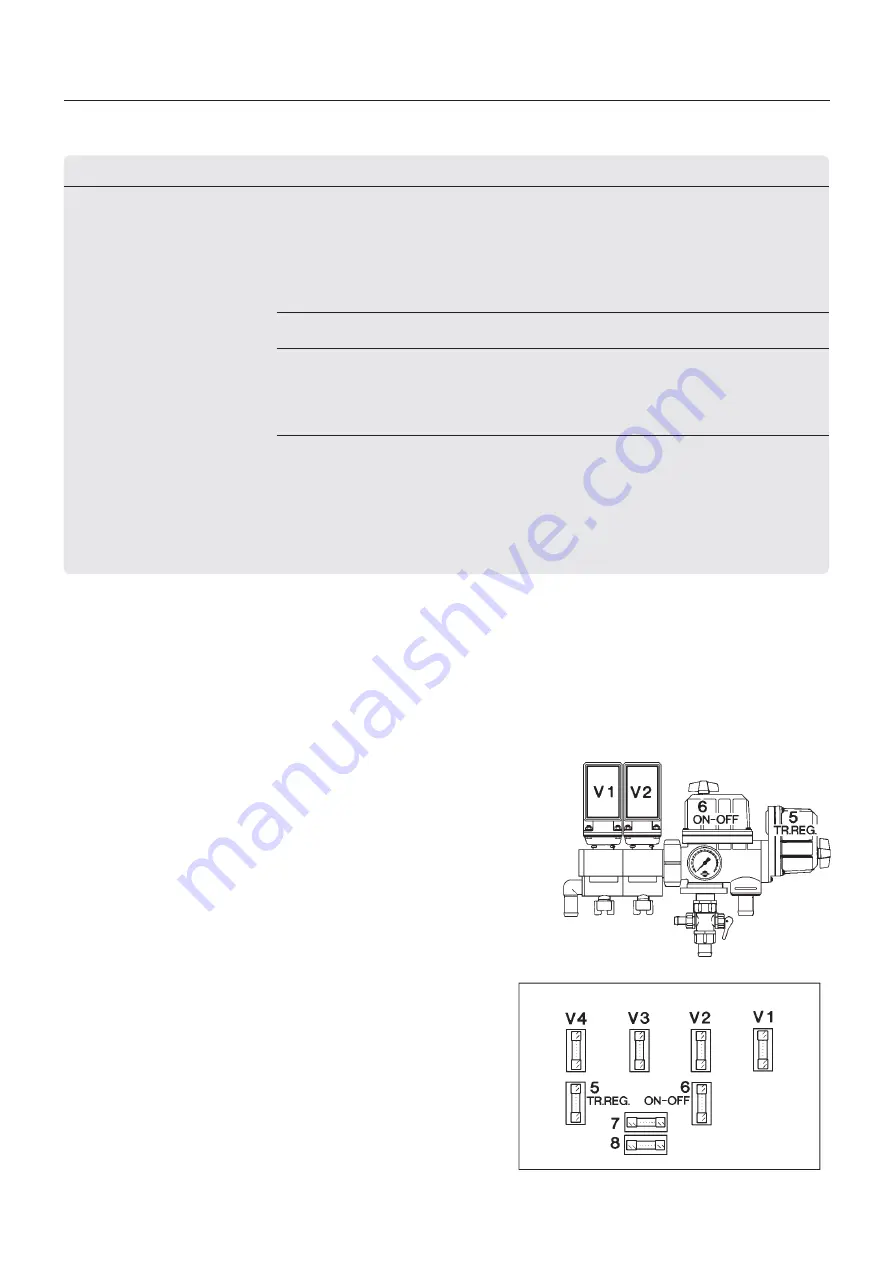

In case of power failure it is possible to operate all functions of the operating unit manually. First disconnect the multiplug

from the control box. Now manually turn the emergency control knobs.

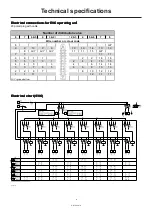

The problem may be due to a blown fuse. The fuses are placed in the control box and are marked according to

functions. Fuses 7 and 8 are spare fuses.

Fuse type T 500 mA HARDI ref. no. 261125