6 - Maintenance

140

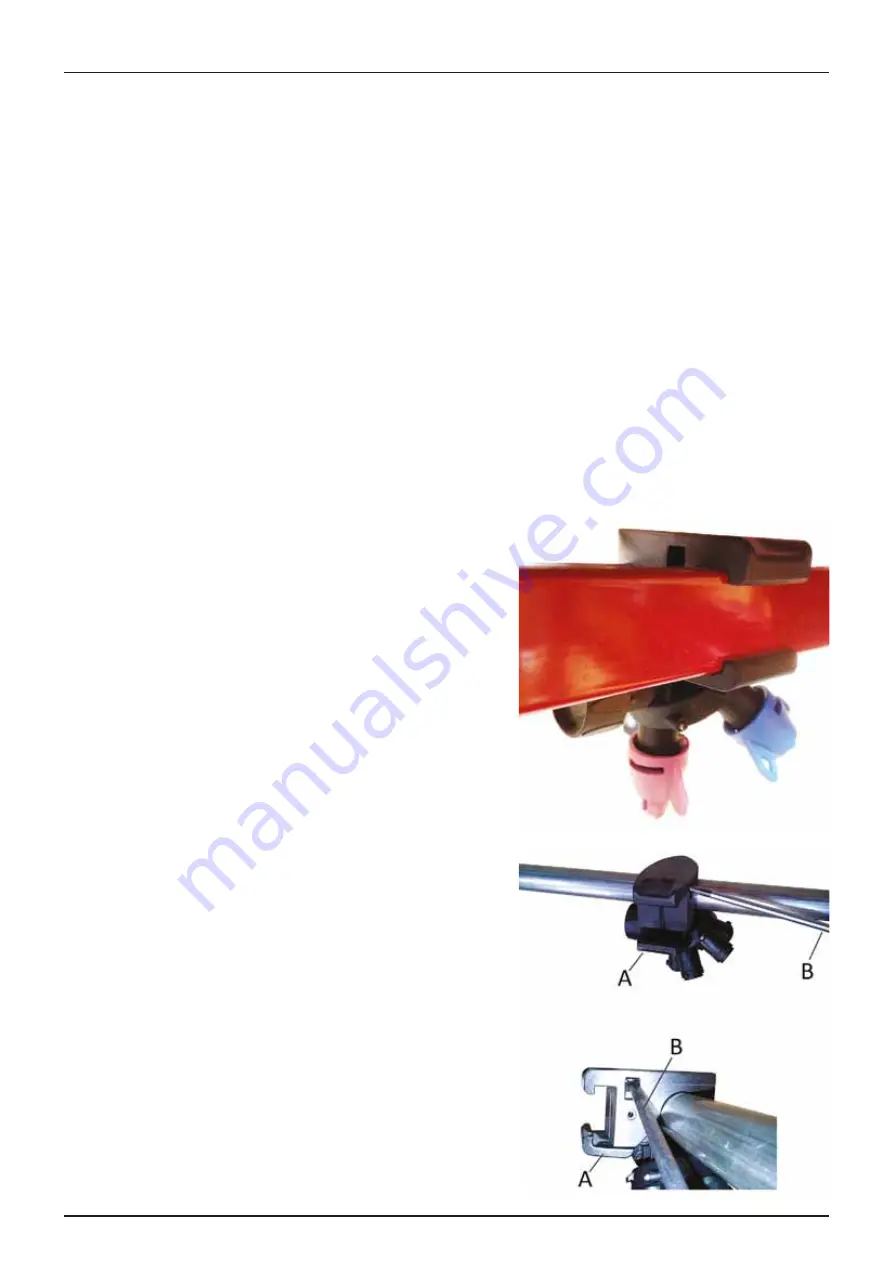

Nozzle Holder Assembly

If leaks of fluid occur in the nozzle holders on the spray boom, it is necessary to check the gaskets. The nozzle holder need

to be disassembled to locate the gaskets. Occasional maintenance of the gaskets and nozzle holders is recommended.

Poor sealings are usually caused by:

•

Missing O-rings

•

Damaged or incorrectly seated O-rings

•

Dry or deformed O-rings

•

Foreign objects.

In Case of Leaks

1.

Disassemble the pipe fitting.

2.

Check condition and position of O-ring. Replace it if damaged or cracked.

3.

Clean and lubricate the O-ring. Lubricate all the way around using a non-mineral lubricant.

4.

Reassemble the O-ring or gasket and pipe fittings. When tightening the fittings, a little mechanical leverage may be

used.

How To Disassemble Nozzle Holders

Nozzle holder assembled and mounted on the spray boom.

The black plastic parts are snapped together.

To disassemble, insert a slotted screwdriver (B) and press, until the

locking piece (A) snaps out.

Summary of Contents for MEGA VPZ MASTER

Page 4: ...1 EU Declaration 4...

Page 10: ...Table of Contents 10...

Page 42: ...2 Safety Notes 42...

Page 68: ...3 Description 68...

Page 118: ...5 Operation 118...

Page 121: ...6 Maintenance 121 Lubrication Plan Boom Centre Close up of Glide Shoes to be Lubricated...

Page 172: ...8 Technical Specifications 172...

Page 176: ...Index 176...

Page 178: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 N rre Alslev DENMARK...