6 - Maintenance

1. 9

250 Hour Servicing

Readjustment of Boom- 250 hour intervals

The boom should be checked and adjusted every 250 hours or as necessary, details of adjusting procedures are

covered in the occasional maintenance section.

Hydraulic Circuit- 250 hour intervals

Check the hydraulic circuit for leaks and repair if necessary.

€

DANGER: Never use hands to check for hydraulic leaks, use a piece of cardboard or similar.

±

WARNING: Hoses for boom lift must be replaced every 5 years.

Hoses and Tubes- 250 hour intervals

Check all hoses and tubes for possible damage, pinching and proper attachment. Replace damaged hoses or tubes.

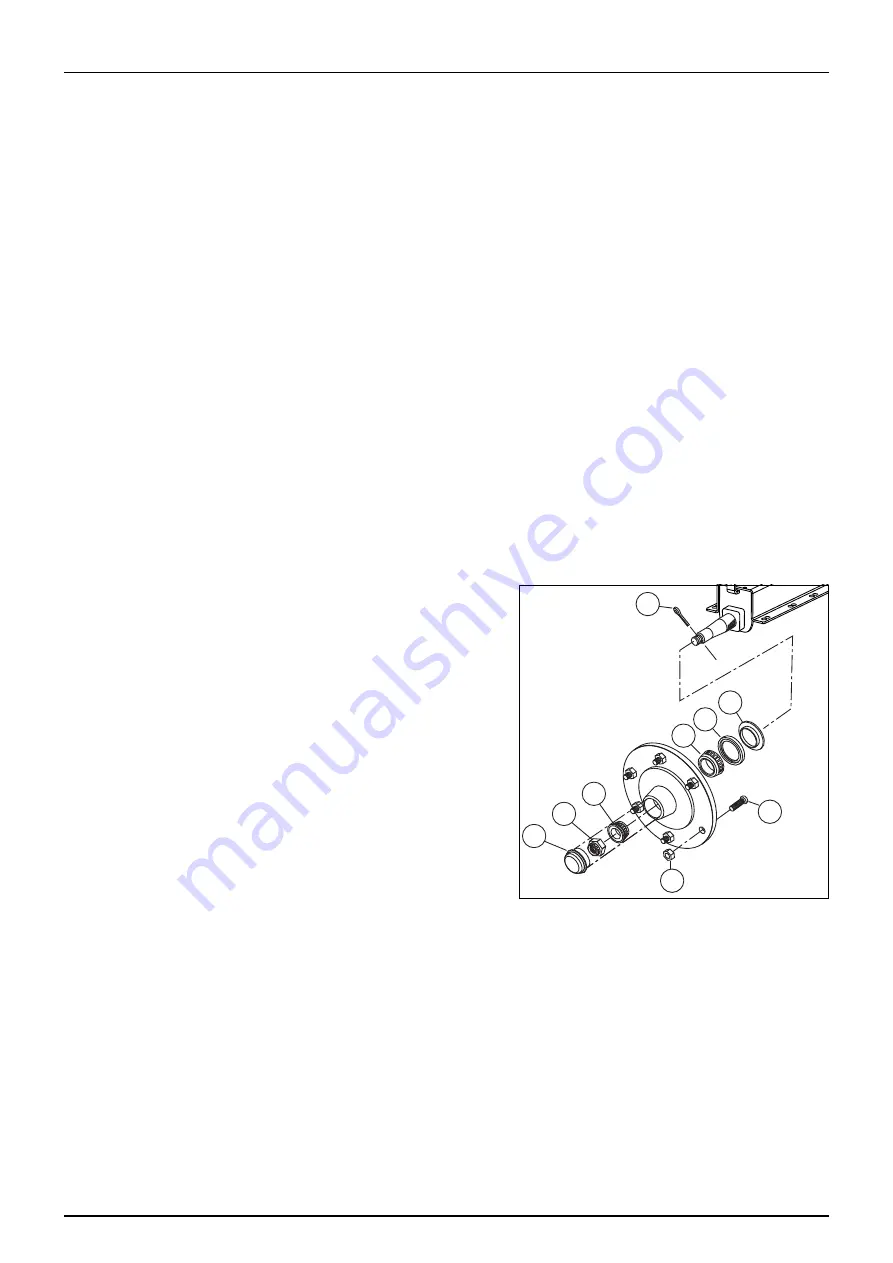

Wheel Bearings - 250 hour intervals

±

WARNING: If you do not feel totally confident changing wheel bearings, contact your HARDI® dealer’s

workshop.

Check for play in the wheel bearings:

•

Place stop wedges in front of and behind LH wheel and jack

up RH wheel.

•

Rock the RH wheel to discover possible play in the bearings.

•

If any play is found, support the wheel axle to prevent the

trailer from moving.

•

Remove hub cap (1) and cotter pin (9). Turn the wheel and

tighten the castle nut (2) until a slight resistance in the wheel

rotation is felt.

•

Loosen the castle nut until the first notch - horizontal or

vertical - is aligned with the cotter pin hole in the shaft.

•

Fit a new cotter pin (9) and bend it over the end of the axle.

•

Fill the hub cap with fresh grease and screw it on to the hub

again.

Repeat the procedure on LH hub assembly.

Refit wheels and torque wheel nuts to 330Nm (243 ft.lb)

1

2

3

4

5

6

7

8

9

Summary of Contents for Mercury Covamax series

Page 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Page 10: ...Table of Contents TOC 8...

Page 18: ...2 Safety 2 6...

Page 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Page 92: ...7 Fault Finding 1 4...

Page 100: ...8 Technical Specifications 8 8...