6 - Maintenance

1. 2

Lubrication

General info

Although the metal parts of the mistblower have received a strong protective surface treatment, it is

recommended to apply a film of anticorrosion oil (e.g. CASTROL RUSTILLO or SHELL ENSIS FLUID) to all metal parts

to prevent discolouration of the enamel by the chemical products; it will also make it easier to clean the

mistblower.

÷

Note: The surface protectant treatment should be repeated every time the protective film is washed off.

To avoid contamination from dirt and condensed water, always keep lubricants clean, dry and cool - preferably at

a constant temperature.

Keep oil filling jugs, hoppers and grease guns clean, and clean the lubricating points thoroughly before applying

lubricant.

Avoid skin contact with mineral oil products for long periods.

Always follow the directions concerning recommended quantity. If no recommended quantity is given, feed the

lubricator until new grease becomes visible.

Pictogram in lubrication & oiling plans indicate the following:

•

Lubricant to be used

•

Operating hours before next lubrication

÷

Note: If the sprayer is cleaned with a high pressure cleaner full lubrication of the entire machine is

recommended.

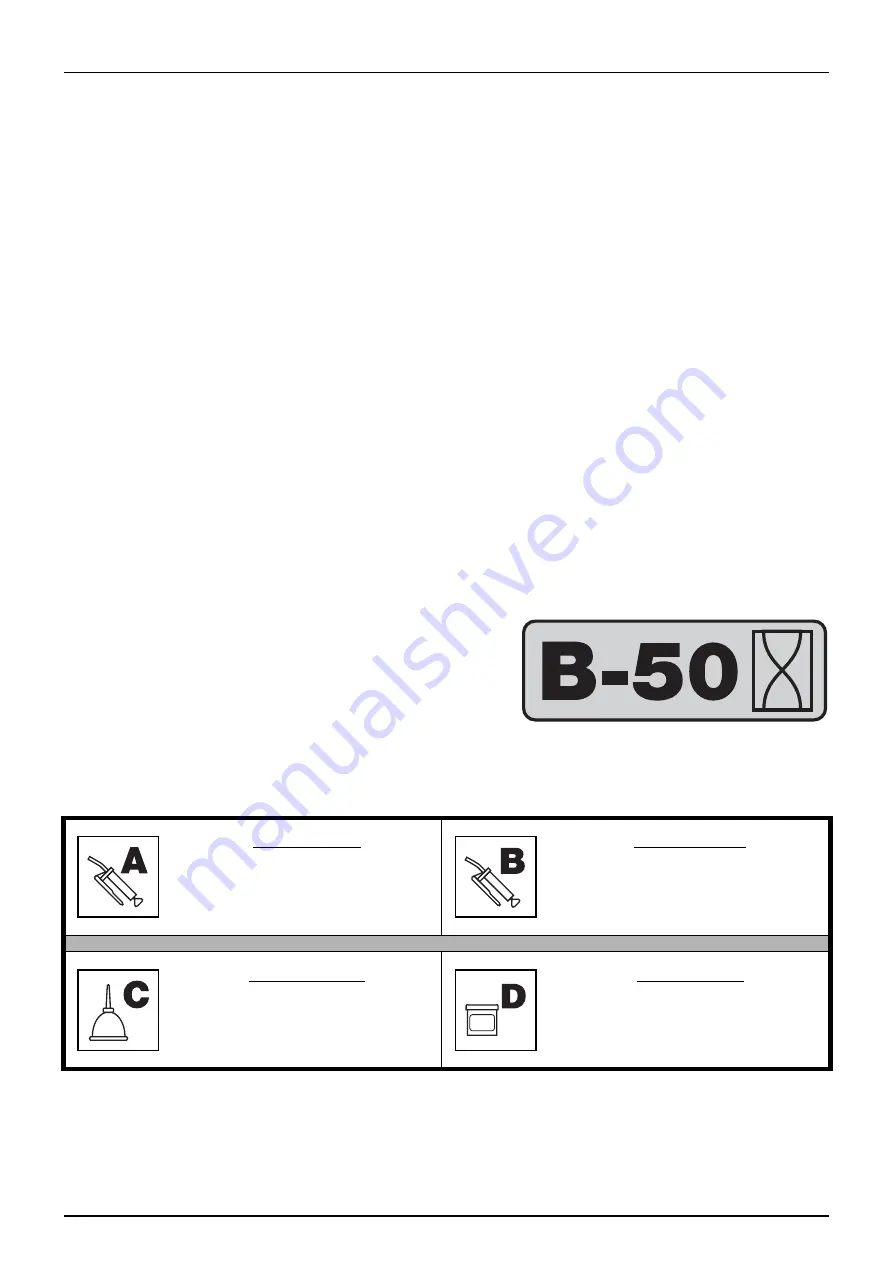

Lubrication Pictogram

The pictogram shown may be used to determine the lubricant

required for the job and the frequency that the task should be

carried out.

The example shown represents the following;

•

B = lubricant type - (Molybdenum-Dysulphide Grease)

•

50 = task frequency - (50 hour intervals)

Recommended lubricants

BALL BEARINGS

Castrol EPL2 Grease or equivalent.

SLIDE BEARINGS

Castrol Molybdenum-disulphide grease

or equivalent

OIL LUBE POINTS

Castrol EPX 80W/90 or equivalent

“O” RING SEALS

Castrol Non-mineral based Rubber

grease or equivalent

Summary of Contents for Mercury Covamax series

Page 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Page 10: ...Table of Contents TOC 8...

Page 18: ...2 Safety 2 6...

Page 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Page 92: ...7 Fault Finding 1 4...

Page 100: ...8 Technical Specifications 8 8...