6 - Maintenance

1. 5

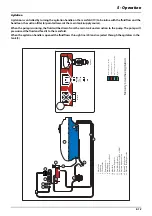

O-Ring and Filter lubrication

Whenever dismantling any filter or hose pipe take care not to

pinch the o-rings fitted to them. When replacing the pipe fitting,

smear the o-ring with oil or grease so that it falls easily into place

in its groove.

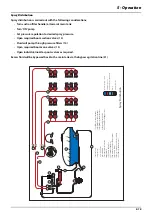

Gearbox lubrication

The gearbox has a sight gauge that should be checked regularly

and the oil should be changed every 250 hours.

The gearbox contains 1 litre of SAE-20/50 multigrade oil

•

Item 1 - Sight Gauge

•

Item 2 - Oil Fill

•

Item 3 - Oil Drain Plug

To allow for easy access when filling the gearbox with oil, a remote

filling tube is fitted fron the fill point on top of the gearbox and

extends to the boom centre frame where it has a capped fitting in

an easily accessible area.

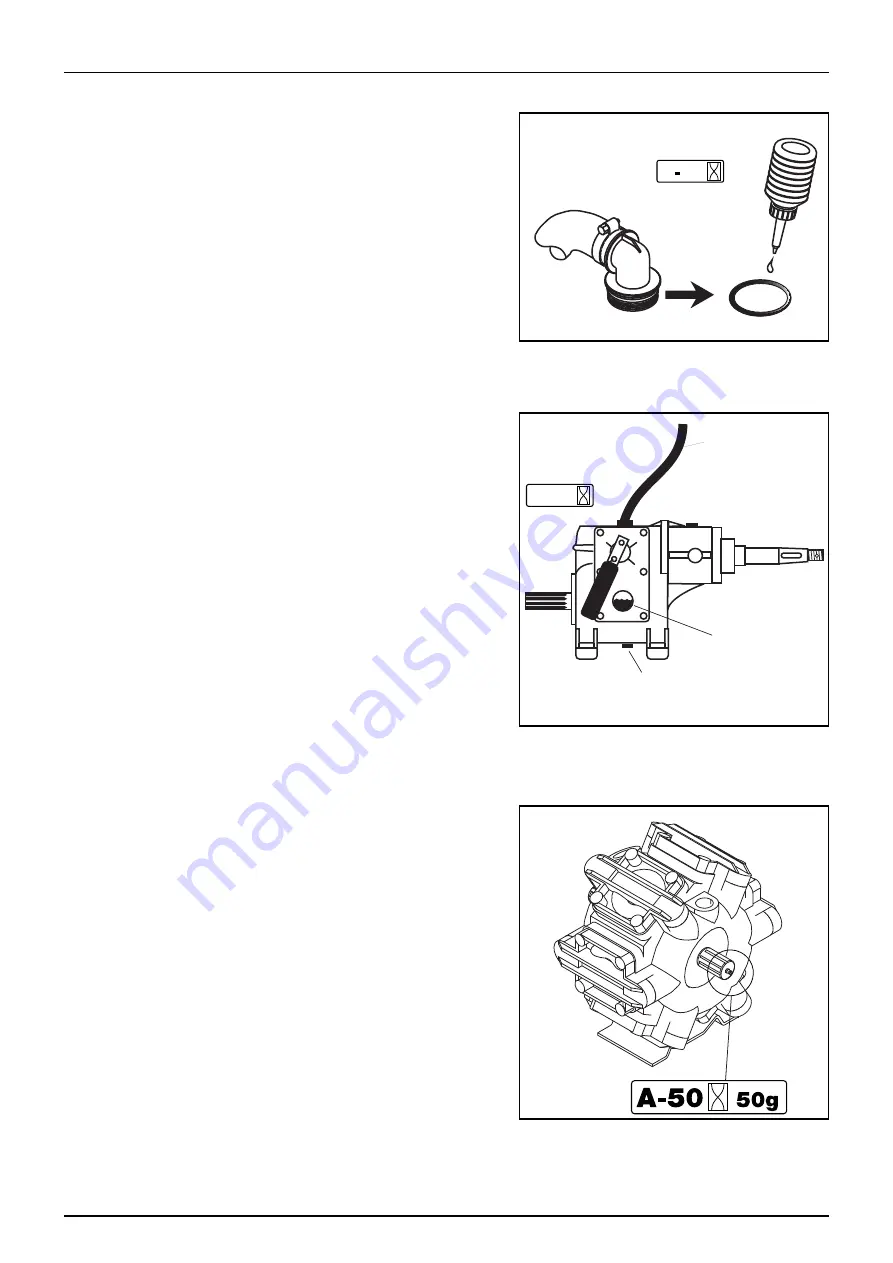

Pump Maintenance

On HARDI 363 pumps, grease the pump, every 50 working hours or

once a month, through the grease nipple situated on the end of

the input shaft. The grease goes along the grooves in the shaft to

reach the crankcase where it is distributed around bearings,

conrods, etc.

AR high pressure series pumps use wet sump lubrication. It is

recommended to check oil level before starting and change oil

after the first 50 hours of operation then regularly at 500 hour

intervals with SAE 30W oil. For servicing and troubleshooting

please refer to AR Pumps documentation or their website.

D 50

SIGHT GAUGE

DRAIN PLUG

FILL - 1 LITRE CAPACITY

250

SAE 20/50

REMOTE FILLING TUBE

Summary of Contents for Mercury Covamax series

Page 1: ...MERCURY COVAMAX Operator Instruction Manual 67002404 100 HAU 08 2009 www hardi com au...

Page 10: ...Table of Contents TOC 8...

Page 18: ...2 Safety 2 6...

Page 88: ...6 Maintenance 1 18 Maintenance Activity Record Date Service Performed...

Page 92: ...7 Fault Finding 1 4...

Page 100: ...8 Technical Specifications 8 8...