53

HARDI

®

N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

6.2 Filters

IMPORTANT: Wear protective clothing when servicing & handling

components that have been in contact with spray liquid.

Clean fi lters ensure :

• Sprayer components such as valves, diaphr agms and operat ing unit

are not hindered or damaged during operation.

• Nozzle blockages do not occur while spray ing.

• Long life of pump. A blocked suction fi lter will result in pump cavit-

ation.

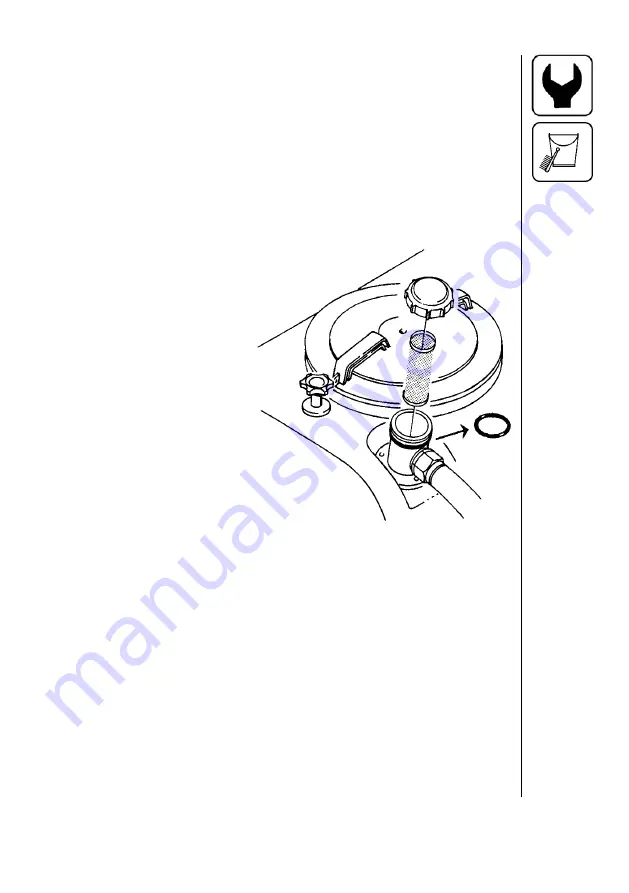

Suction fi lter

The main fi lter protecting spray er com po nents is

the suc tion fi l ter at the top of the tank. Check

it reg u lar ly. Make sure the O-ring on the

fi lter housing is in good condition and

lubricated*.

Pressure fi lter (BK-3 Control Unit only)

The BK-3 Control unit is equipped with a built-in pressure fi lter.

Unscrew the base to check and clean the fi lter. Make sure the O-ring

on the fi lter housing is in good condition and lubricated*.

*HARDI

®

recommends using a vegetable based oil to prolong the life of

the O-ring.