4 - Sprayer setup

53

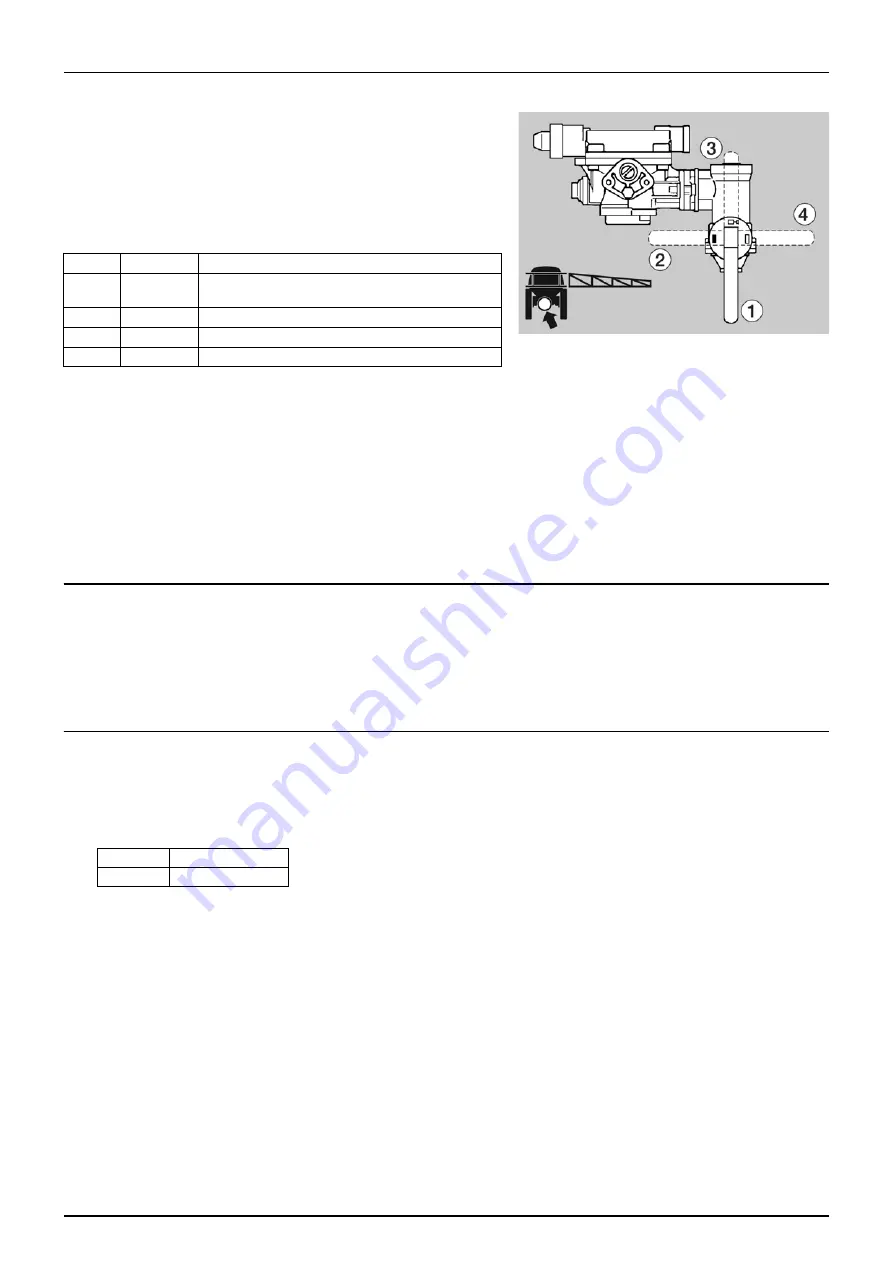

Air activated brakes (optional)

This system requires a tractor with compressor and air brake system with

outlet(s) for trailer brakes.

If the air hose(s) are disconnected with air in the brake air tank, control

pressure will be dumped and the brakes will engage fully.

If the sprayer e.g. must be moved, the load apportioning valve must be

set. Remember to reset the handle to brake position again afterwards.

*If axle load exceeds 5250 kg. position 2 is required to be used.

μ

ATTENTION! When parking the sprayer, always engage the parking brake, as the air brakes will only be engaged as

long as there is air in the tank! Cover the couplings with the dust flaps when hoses are disconnected.

μ

ATTENTION! The load apportioning valve must be set at the position corresponding to the load on the trailer, for

obtaining optimal air pressure to the trailer brakes.

±

WARNING! Driving with wrong load apportioning valve setting, will make the brakes under- or overapply, which can

cause hazardous situations.

Single-line brakes (optional)

1.

Flip the snap coupler protection flap away.

2.

Connect the snap coupler to the tractor outlet (black).

3.

Let the compressor fill the sprayer’s air reservoir.

4.

Check brake circuit for leaks.

Dual-line brakes (optional)

1.

Flip the snap coupler protection flaps away.

2.

Connect the two snap couplers for supply and control to the tractor outlets. The couplers are colour coded and

secured against incorrect attachment:

3.

Let the compressor fill the sprayer’s air reservoir.

4.

Check brake circuits for leaks.

Position

State

Use

1

Relieved

Move sprayer with air in the tank and without the air hose(s)

connected to the tractor. Disengages the brakes.

2

Full

Use when driving with full tank.

3

Half full*

Use when driving with tank half full.

4

Empty

Use when driving with empty tank.

Red

Supply line (RH)

Yellow

Control line (LH)

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...