5 - Operation

62

Safety precautions - crop protection chemicals

Always be careful when working with crop protection chemicals!

±

WARNING! Always wear proper protective clothing before handling chemicals!

Personal protection

Depending on chemical type, protective gear/equipment should be worn to avoid contact with the chemicals, e.g.:

•

Gloves

•

Waterproof boots

•

Headgear

•

Respirator

•

Safety goggles

•

Chemical resistant overall

±

WARNING! Protective clothing/equipment should be used when preparing the spray liquid, during the spray job and

when cleaning the sprayer. Follow the chemical manufacturer’s instructions given on the chemical label and/or local

legislation.

±

WARNING! It is always advisable to have clean water available, especially when filling the sprayer with the chemical.

±

WARNING! Always clean the sprayer carefully and immediately after use.

±

WARNING! Only mix chemicals in the tank according to directions given by the chemical manufacturer.

±

WARNING! Always clean the sprayer before changing to another chemical.

Filling chemicals through tank lid

The chemicals are filled through the tank lid - Note instructions on the chemical container!

±

WARNING! Be careful not to slip or splash chemicals when carrying chemicals up to the tank lid!

μ

ATTENTION! Due to risk of spillage and spot contamination it is not allowed in several countries to fill chemicals

directly through the tank lid. Use the TurboFiller for all induction of chemicals instead.

1.

Make sure the spray control unit is switched off.

2.

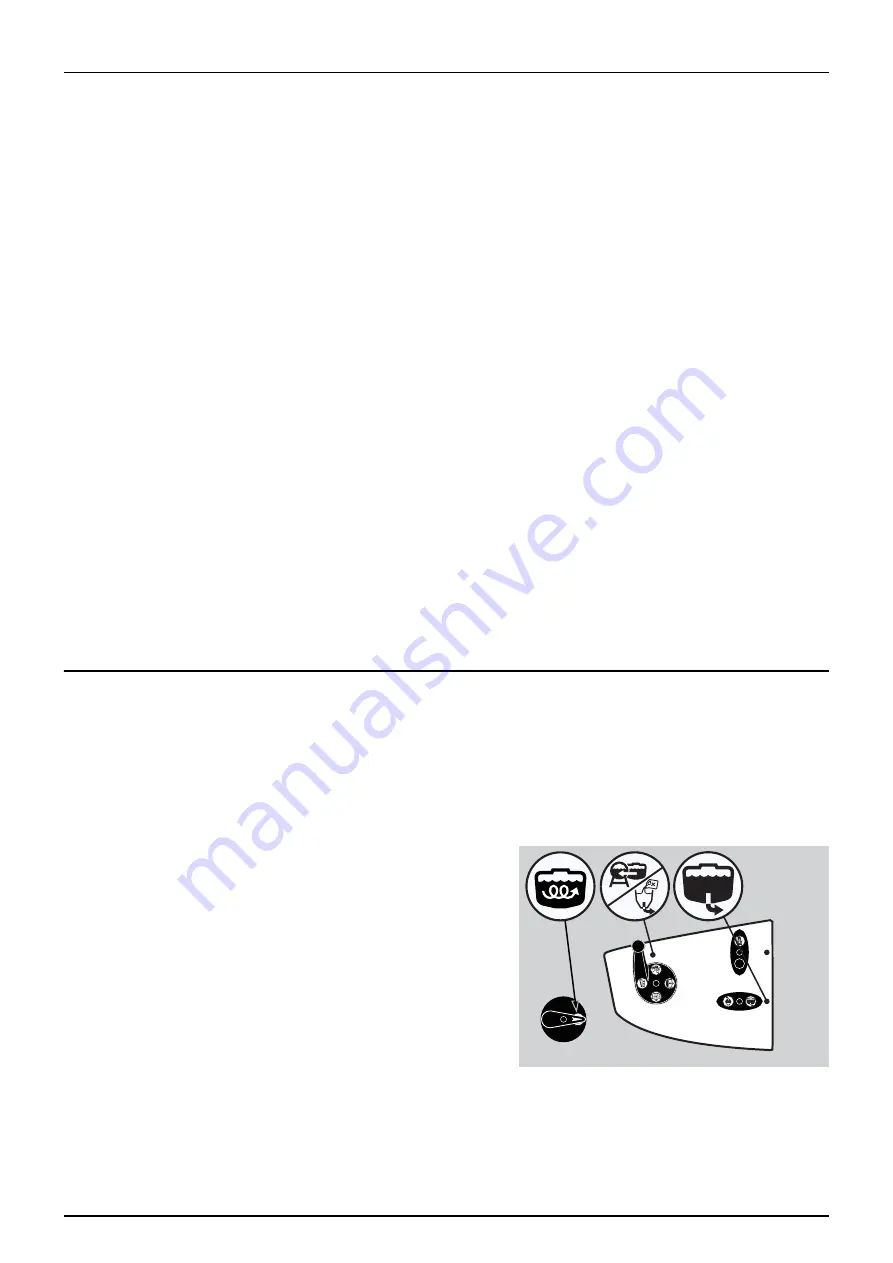

Set suction valve towards “Suction from main tank”, Agitation valve

towards “Agitation”. Turn pressure SmartValve towards “Spraying”.

3.

Engage the pump and set P.T.O. revolutions to 540 r.p.m.

4.

Add the chemicals through the main tank hole.

5.

When the spray liquid is well mixed, turn handle on the pressure

SmartValve towards “Spraying” position. Keep P.T.O. engaged so

the spray liquid is continuously agitated until it has been sprayed

on the crop.

€

DANGER! Before turning Pressure SmartValve to “Pressure

draining/TurboFiller” it is very important to be sure that the quick coupler lid is correct and completely mounted to

the filling stud into its locked position. Failure to do so may cause risk of contamination and injury from quick coupler

lid being “shot” off when pressurized! If not possible to mount lid completely, lubricate the rubber seal and the grip

hooks.

÷

NOTE! Local legislation may not allow filling through the tank lid, but will require use of the chemical inductor instead.

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...