5 - Operation

72

Rinsing when main tank is not empty

Rinsing the pump, operating unit, spray lines, etc. in case of stop in spraying before main tank is empty (e.g. beginning rain

etc.).

Cleaning of the liquid system:

1.

Turn suction valve towards

. (Keep pressure SmartValve in

-position).

2.

Close AgitationValve (no agitation).

3.

Engage the pump and spray the water from the rinsing tank in the field until all nozzle tubes/nozzles have been

flushed with clean water.

4.

Disengage pump again.

μ

ATTENTION! It is advisable to increase the forward speed (double, if possible) and reduce the pressure to 1.5 bar (20

psi) when spraying diluted remaining liquid in the field just sprayed.

1.

Cleaning the sprayer on the outside

Turn suction valve towards

and pressure SmartValve towards ”Internal Tank

Cleaning”.

2.

When another 1/3 of the contents in the rinsing tank is used, turn the suction valve towards

.

3.

Turnpressure Agitation valve towards “External Cleaning Device” and wash the sprayer with the cleaning device

located on sprayer’s right side.

4.

Disengage pump again.

μ

ATTENTION! If the sprayer is cleaned with a high pressure cleaner, lubrication of the entire machine is recommended.

Technical residue

Inevitably a quantity of spray liquid will remain in the system. It cannot be sprayed properly on the crop, as the pump takes

in air when the tank is about to be empty.

This Technical Residue is defined as the remaining liquid quantity in the system as the first clear pressure drop on the

pressure gauge is read.

The residues in the tank should be diluted immediately in the relationship 1:10 with water and afterwards be sprayed to the

crop just sprayed with increased driving speed. In addition, also pump, linkage and armature can be separately rinsed with

water from the rinsing tank. It is to be made certain however that the liquid in the spray lines are in unchanged

concentration. Therefore there should be an untreated patch available to spray this out.

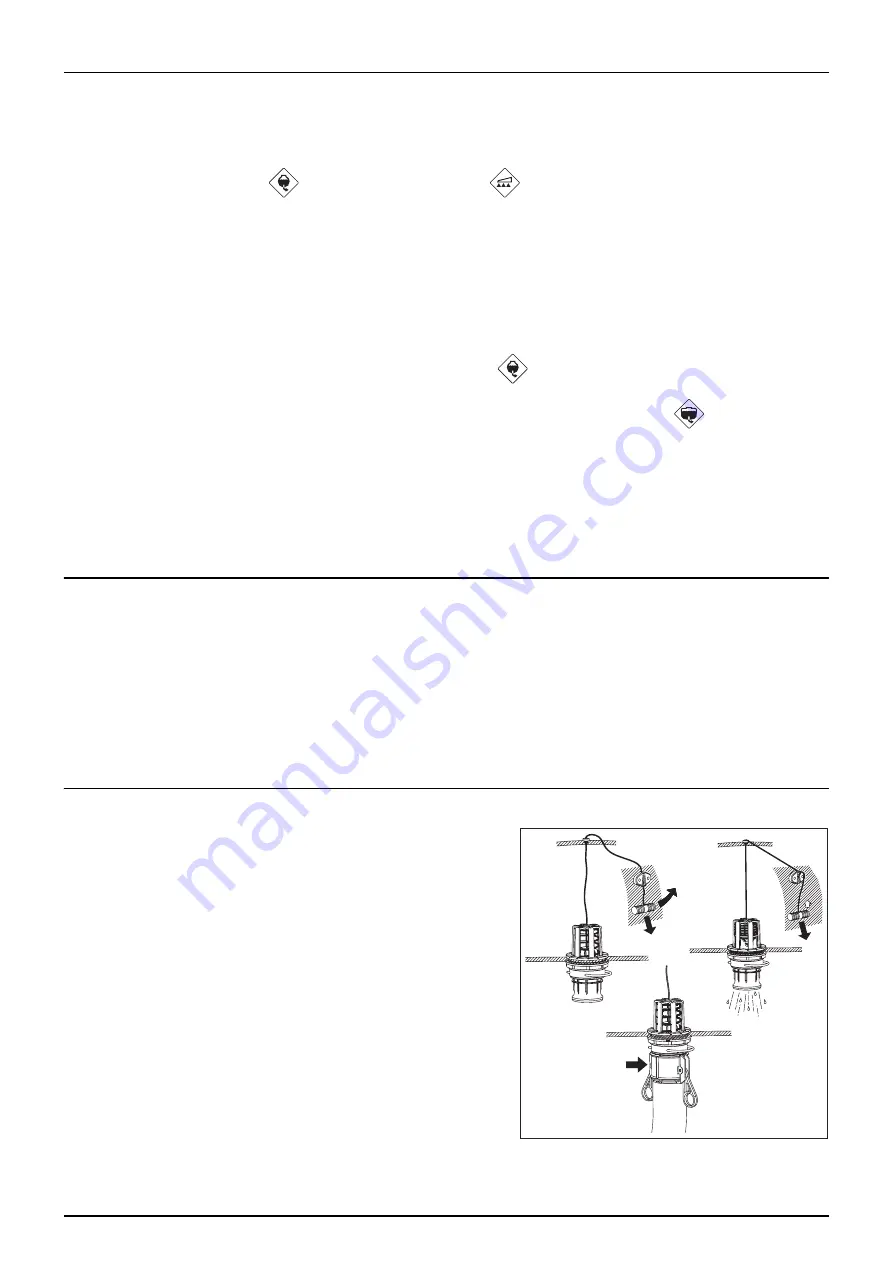

Using the drain valve

The drain valve is operated from platform just beside the main tank lid.

Pull the string to open the drain valve. The valve is spring-loaded, but

can be kept open by pulling the string upwards in the V-shaped slit. To

release, pull the string downward and the valve will close automatically.

If draining residues, e.g. liquid fertilizer into a reservoir, a snap-coupler

with hose can rapidly be connected to the drain valve and the liquid

safely drained.

Summary of Contents for NAVIGATOR DELTA

Page 4: ...1 EC Declaration 4 ...

Page 10: ...Table of Contents 10 ...

Page 14: ...2 Safety notes 14 ...

Page 32: ...3 Description 32 ...

Page 54: ...4 Sprayer setup 54 ...

Page 74: ...5 Operation 74 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 104: ...7 Fault finding 104 ...

Page 120: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...