5 - Operation

65

μ

ATTENTION! If not flushed with clean water, the hopper rinsing device uses spray liquid for rinsing the hopper!

Cleaning the TurboFiller must always be done, when the spray job is ended, and together with cleaning the entire

sprayer. A cleaning after the last filling, and before spraying, does not ensure a clean TurboFiller!

8.

Close TurboFiller suction valve, when the hopper has been rinsed. Close the lid.

9.

If closed, turn the AgitationValve towards “Agitation”.

10.

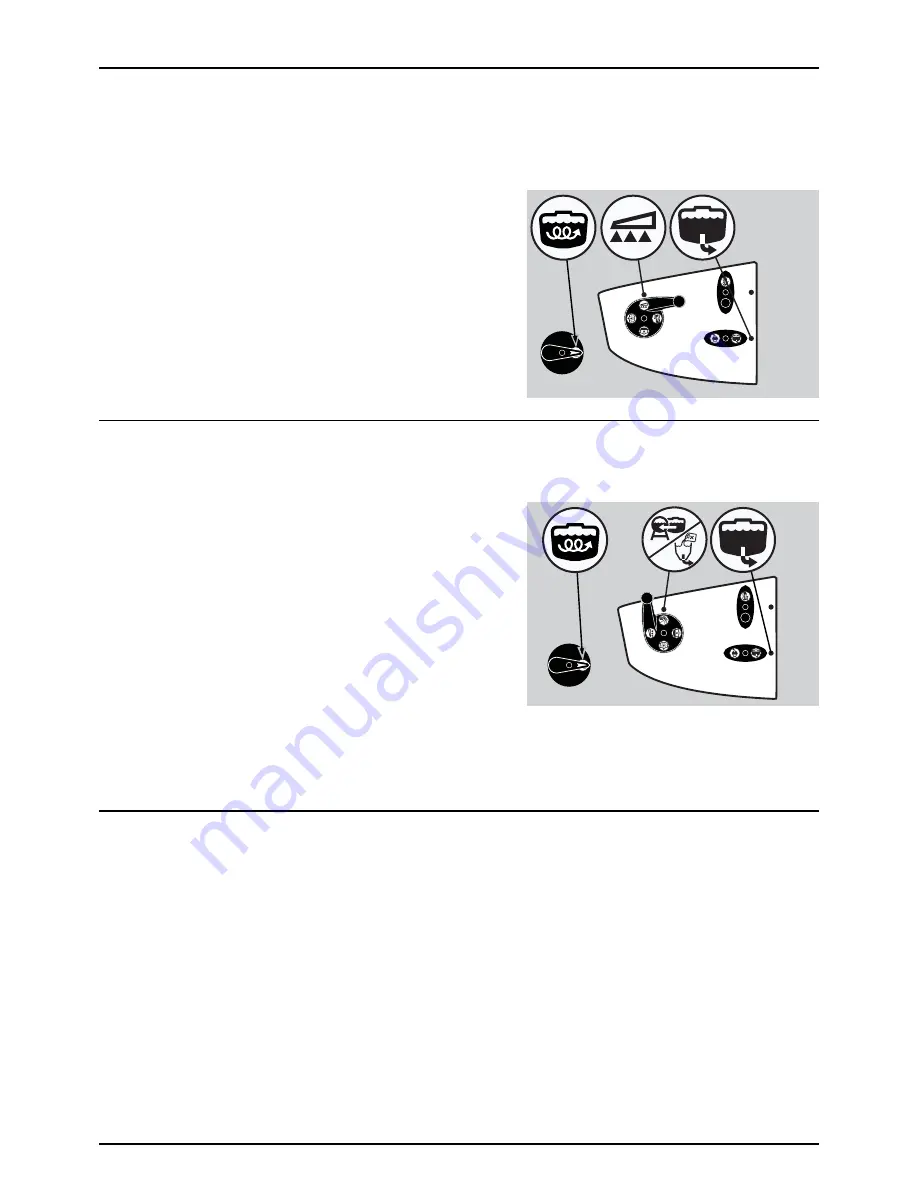

When the spray liquid is well agitated, turn handle of the pressure

SmartValve towards “Spraying” position. Keep PTO engaged, so

that the spray liquid is continuously agitated, until it has been

sprayed on the crop.

Agitation before Resuming a Spray Job

If a spray job has been interrupted for a while, severe sedimentation may occur depending on the chemicals being used.

Before resuming the spray job, it might be necessary to agitate sediment material.

1.

Turn the handle at the suction valve towards “Suction from main

tank”. Turn the pressure alve towards “Pressure

draining/TurboFiller” and turn the Agitation valve towards

“Agitation”. Other valves closed.

2.

Engage the pump and set PTO speed to 540 rpm or 1000 rpm

(depending on pump model).

3.

Agitation has started and should be continued for at least 10

minutes.

4.

The spray job can now be resumed. Turn pressure SmartValve

towards “Spraying” and start spraying.

€

DANGER! Before turning Pressure SmartValve to “Pressure draining/TurboFiller” it is very important to be sure that the

quick coupler lid is correct and completely mounted to the filling stud into its locked position. Failure to do so may

cause risk of contamination and injury from quick coupler lid being “shot” off when pressurized! If not possible to

mount lid completely, lubricate the rubber seal and the grip hooks.

Parking the Sprayer

To avoid spot contamination, the sprayer should always be parked at either the washing/filling location or under roof.

This prevents rainfall from washing down chemical residues from the sprayer's surfaces.

•

Parking at the washing/filling location will retain residues.

•

Always park the machine out of reach of children, animals and unauthorized persons.

Summary of Contents for NAVIGATOR FORCE

Page 4: ...1 EU Declaration 4 ...

Page 12: ...2 Safety Notes 12 ...

Page 54: ...4 Sprayer setup 54 ...

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

Page 112: ...8 Technical specifications 112 ...

Page 116: ...Index 116 ...

Page 118: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...