6 - Maintenance

95

Off-Season Storage

Off-Season Storage Program

To preserve the sprayer intact and to protect its components, the following off-season storage program is carried out.

Before storage

When the spraying season is over, you should devote some extra time to the sprayer. If chemical residues are left over in the

sprayer for longer periods, it may reduce the life of its individual components.

1.

Clean the sprayer completely - inside and outside - as described under “Cleaning” on page 69. Make sure that all valves,

hoses and auxiliary equipment have been cleaned with detergent and flushed with clean water afterwards, so that no

chemical residues are left in the sprayer.

2.

Replace any damaged seals and repair any leaks.

3.

Empty the sprayer completely, and let the pump work for a few minutes. Operate all valves and handles to drain as

much water off the spraying circuit as possible. Let the pump run until air comes out of all nozzles. The rinsing tank is

also drained.

4.

Pour approximately 50 litres of antifreeze mixture, consisting of 1/3 anti-freeze and 2/3 water, into the tank.

5.

Engage the pump and operate all valves and functions, operating unit, chemical inductor etc., allowing the antifreeze

mixture to be distributed around the entire circuit. Open the operating unit main valve ON/OFF and distribution valves,

so that the antifreeze is sprayed through the nozzles as well. The antifreeze will also prevent O-rings, seals, diaphragms

etc. from drying out. On sprayers with a FlexCapacity pump, this must also be engaged and flushed.

6.

Lubricate all lubricating points according to the lubricating intervals.

7.

When the sprayer is dry, remove rust from scratches or damage in the paint, if any, and touch up the paint.

8.

Remove the glycerine-filled pressure gauges and store them frost-free in vertical position.

9.

Apply a thin layer of anti-corrosion oil (e.g. SHELL ENSIS FLUID, CASTROL RUSTILO or similar) on all metal parts. Avoid

oil on rubber parts, hoses and tyres.

10.

Fold the boom in transport position and relieve pressure from all hydraulic functions.

11.

All electric plugs and sockets are to be stored in a dry plastic bag to protect them against moisture, dirt and corrosion.

12.

Remove the control boxes and computer display from the tractor. Store them dry and clean (indoor) in a non-

condensing environment.

13.

Wipe hydraulic snap-couplers clean and fit the dust caps.

14.

Apply grease to all hydraulic ram piston rods, which are not fully retracted in the housing, to protect against corrosion.

15.

Chock the wheels, to prevent moisture damage and deformation of the tyres. Tyre blacking can be applied to the tyre

walls to preserve the rubber.

16.

Drain air brake tank for condensed water.

17.

To protect against dust, the sprayer can be covered by a tarpaulin. Ensure ventilation to prevent condensation.

Summary of Contents for NAVIGATOR FORCE

Page 4: ...1 EU Declaration 4 ...

Page 12: ...2 Safety Notes 12 ...

Page 54: ...4 Sprayer setup 54 ...

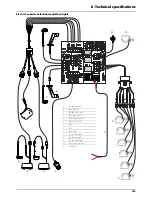

Page 76: ...6 Maintenance 76 Boom lubrication oiling plan ...

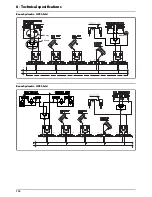

Page 112: ...8 Technical specifications 112 ...

Page 116: ...Index 116 ...

Page 118: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...