6 - Maintenance

140

±

WARNING! Exceeding the maximum torque will result in these risks:

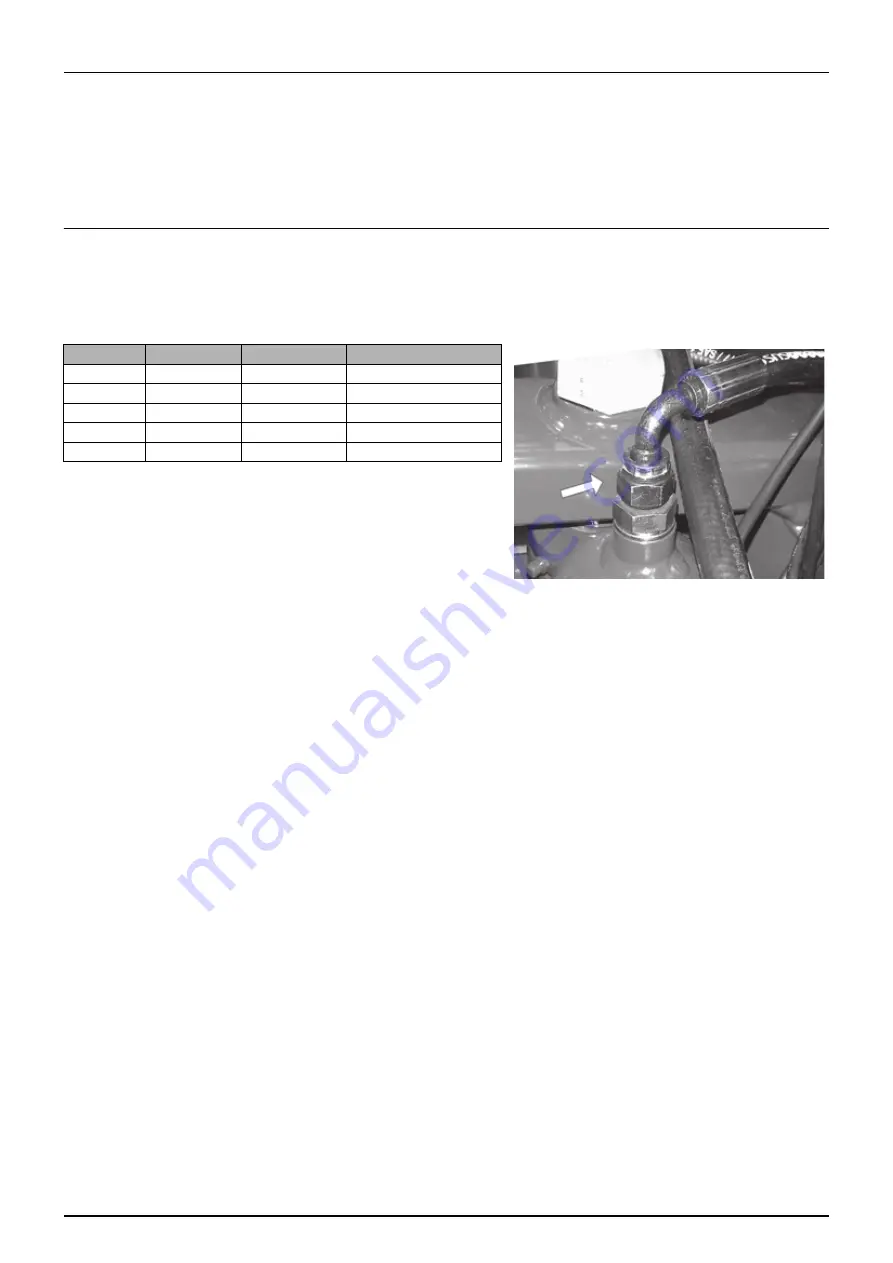

Tightening Hydraulic Hoses

When tightening hydraulic hoses as a part of periodic service or due to replacement of spare parts, it is important to apply

the correct torque. This will prevent accidents and prolong the lifetime of the parts connected with the hoses.

If not stated otherwise in this book, please tighten hydraulic hoses using the following torques:

€

DANGER! A hydraulic hose or joint leaking or coming apart with the oil under pressure can cause severe injuries to

persons standing nearby! The oil can be very hot, around 80 °C, and the oil streaming out can penetrate human skin.

Risk of burns on the skin, internal injuries and facial injuries.

±

WARNING! Applying too little torque will result in these risks:

±

WARNING! Applying too much torque will result in these risks:

±

WARNING! When assembling a hydraulic joint, this is often being twisted around in different directions to make it fit

between other components on the sprayer. Remember to finish off by applying the correct torque.

÷

NOTE! The sealing system for hoses and fittings is ORFS type (O-Ring Face Seal). This ensures a high level of sealing

and good vibration resistance. The fittings use the O-ring compression mechanism to seal.

•

Damaging or stripping the threads and deforming the bolt.

•

Bolt heads will be broken.

•

Bolted joints will come loose.

•

Accidents caused by assembled parts coming apart due to bolts breaking at a later time.

Hose Size

Thread Size

Spanner Size

Recommended Torque

1/4“

9/16“

19 mm

28 Nm

3/8“

11/16“

22 mm

44 Nm

1/2“

13/16“

24 mm

62 Nm

3/4“

1.3/16“

36 mm

130 Nm

1“

1.7/16“

41 mm

170 Nm

•

Hydraulic joints will leak due to the high oil pressure.

•

Hydraulic joints will rattle and thus fail under fatigue.

•

Hydraulic joints are being worn quickly and thus will not fulfil their design purpose.

•

Accidents caused by sudden loss of oil pressure due to hydraulic parts coming apart.

•

Damaging or stripping the threads and deforming the hydraulic joints.

•

Fittings will be broken.

•

Hydraulic joints will leaks.

•

Accidents caused by assembled parts coming apart due to bolts breaking at a later time.

Summary of Contents for NAVIGATOR VPZ

Page 4: ...1 EU Declaration 4...

Page 72: ...3 Description 72...

Page 135: ...6 Maintenance 135 Lubrication Plan Boom Wings 10...

Page 174: ...6 Maintenance 174...

Page 182: ...7 Fault Finding 182...

Page 195: ...8 Technical Specifications 195 Hydraulic Diagrams Hydraulics for Boom of 21 24 Meters...

Page 196: ...8 Technical Specifications 196 Hydraulics for Boom of 27 28 Meters...

Page 198: ...8 Technical Specifications 198...

Page 204: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 N rre Alslev DENMARK...