20

HARDI

®

New NAVIGATOR OPERATOR’S MANUAL

Emergency operation

In case of electrical failure, it is still possible to man u al ly

override all func tions of the operating unit. To operate

manually, disconnect the multiplug from the ECP or

ECPC control box fi rst and operate the handles by

hand. It is possible to change pressure and turn booms

on or off.

Note:

Since the ON/OFF switch normally op er ates by

shutting off all boom dis tri bu tion valves, you will need

to manually shut off all distribution valves to shut off the

complete control unit manually.

IMPORTANT! When the sprayer is stored, the ECP

or ECPC control box and the multiplug must be

pro tect ed against moisture and dirt. A plastic bag

may be used to protect the multi plug. Store the

control box in a clean dry place.

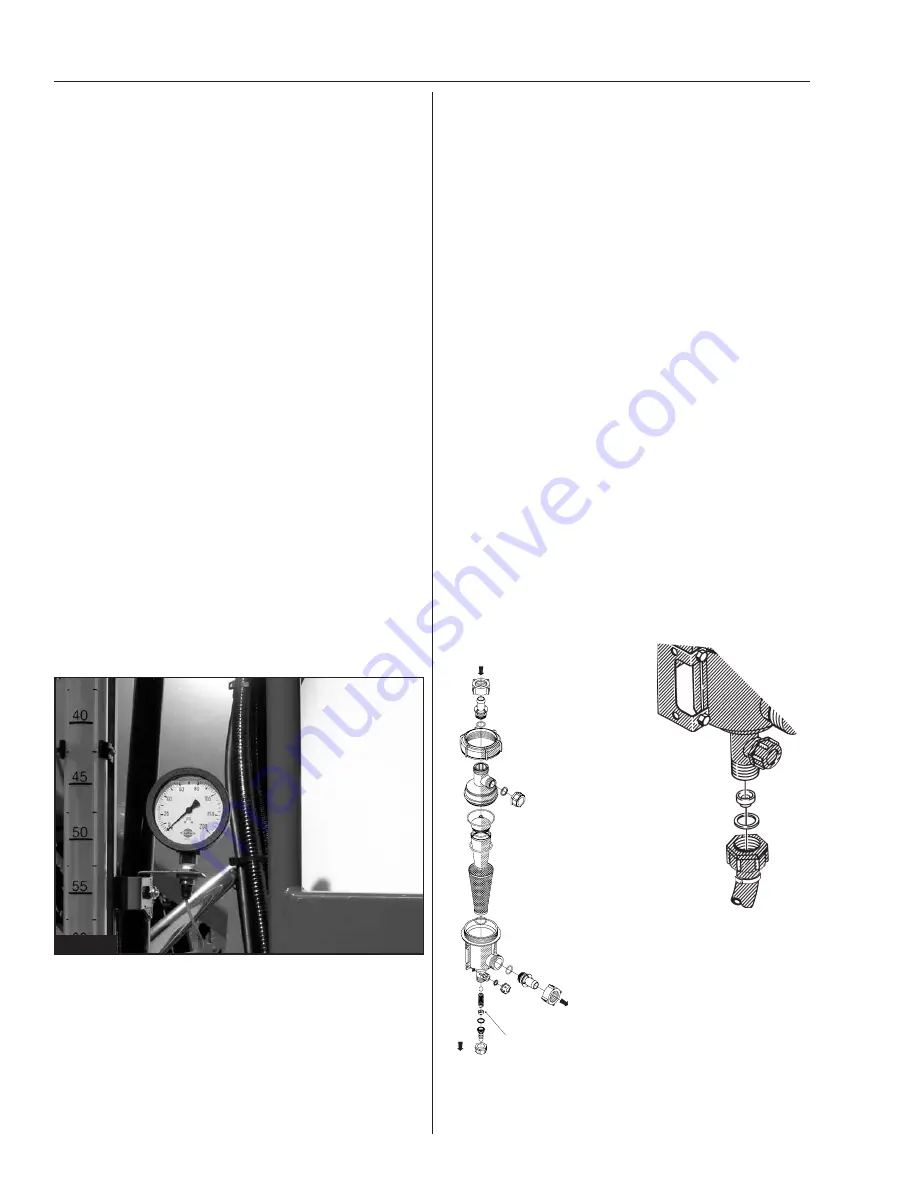

Remote 4” pressure gauge (optional)

The remote pressure gauge is located on the front

handrail (

Fig 20). This gauge measures the working

pressure in the boom tubes as close to the nozzles as

possible. This pressure reading will always be slightly

lower than the reading at the operating unit pressure

gauge.

The outputs stated in the nozzle charts are always

based on the pressures measured at the nozzle.

Always adjust pressure when calibrating and spraying

according to readings at the Remote pressure gauge.

Filters

Filters should always be used, and their function

checked regularly. The mesh size of the fi lter

should always be smaller than the fl ow average of

the nozzles used. Therefore, pay attention to the

correct com bi na tion of fi lters and mesh size. The

recommended suc tion fi lter is 50 mesh - this allows

good fl ow to the pump with little restriction. The

standard self cleaning fi lter is 100 mesh.

Refer to the chart below for correct fi lter rec om men da tions.

ISO Flat Spray

Suction Self Cleaning In-Line Nozzle

Nozzle Size Filter Filter Filter Filter

075-01-015-02

50 100 100 100

025-03

50 80 80 80 (50)

04 and larger

30 80 (50) 50 50

Suction fi lter screens do wear from dirt and chemical

particles. If nozzle fi lters continually block with chem i cal

particles, then use the next size coarse nozzle fi lter.

Self cleaning fi lter (ECP only)

IMPORTANT!

Note direction of restrictor in (

Fig 21).

Correct restrictor choice

It is important to have a large fl ow through the fi lter.

This is achieved by choosing restrictor size in relation

to the liquid consumption of the spray boom and pump

output.

Four restrictors are supplied. Use the green one

(largest orifi ce) fi rst.

Disconnect the hose (

Fig 21) at the self cleaning fi lter,

place the restrictor in the hose and reconnect.

If the required working pressure cannot be obtained,

the restrictor is too large. Choose a smaller one;

Starting with black, then white and fi nally red.

Operation

A

B

C

F

E

D

334200 RED 334201 WHITE

334202 BLACK 334203 GREEN

A= From Pump

B= Double Filter Screen

C= Guide Cone

D= To Operating Unit

E= Replaceable Restrictor

F= Return to Tank

Fig 21

Fig. 20

Summary of Contents for New NAVIGATOR 1100

Page 1: ...New NAVIGATOR 67020803 10 04 Operator s Manual ...

Page 2: ......

Page 34: ...32 HARDI New NAVIGATOR OPERATOR S MANUAL 7 Maintenance 6 C 500h B 50h ...

Page 57: ...55 HARDI New NAVIGATOR OPERATOR S MANUAL Notes ...

Page 58: ...56 HARDI New NAVIGATOR OPERATOR S MANUAL Notes ...

Page 59: ......