6 - Maintenance

100

Change of Light Bulb

1.

Switch off the light.

2.

Loosen the screws on the lamp and remove the cover or lens.

3.

Remove the bulb.

4.

Fit a new bulb, refit the cover and tighten the screws.

μ

ATTENTION! If halogen bulbs are used, never touch the bulb with your fingers. Natural moisture in the skin will cause

the bulb to burn out, when the light is switched on. Always use a clean cloth or tissue when handling halogen bulbs.

Venting the Boom Hydraulics

If the hydraulic cylinders or hoses have been dismantled, it is necessary to vent the cylinders after reassembly.

€

DANGER! Failing to vent the hydraulic system when needed may result in violent boom movements and poor boom

performance. Risk of damage to the boom parts or foreign objects nearby. Risk of severe injuries or death.

μ

ATTENTION! To vent the hydraulic cylinders you must loosen the hydraulic hose connected to the cylinder to let the

air out this way. Note that ORFS fittings are used - be careful not to damage the sealing O-ring, when venting oil.

μ

ATTENTION! The following venting instructions are for the optional double acting tilt cylinders only. For the single

acting lift cylinder, the venting is easily completed: After service, apply hydraulic pressure to the cylinder, retract and

extend the piston approx. 5 times, and the air is then removed from the system automatically.

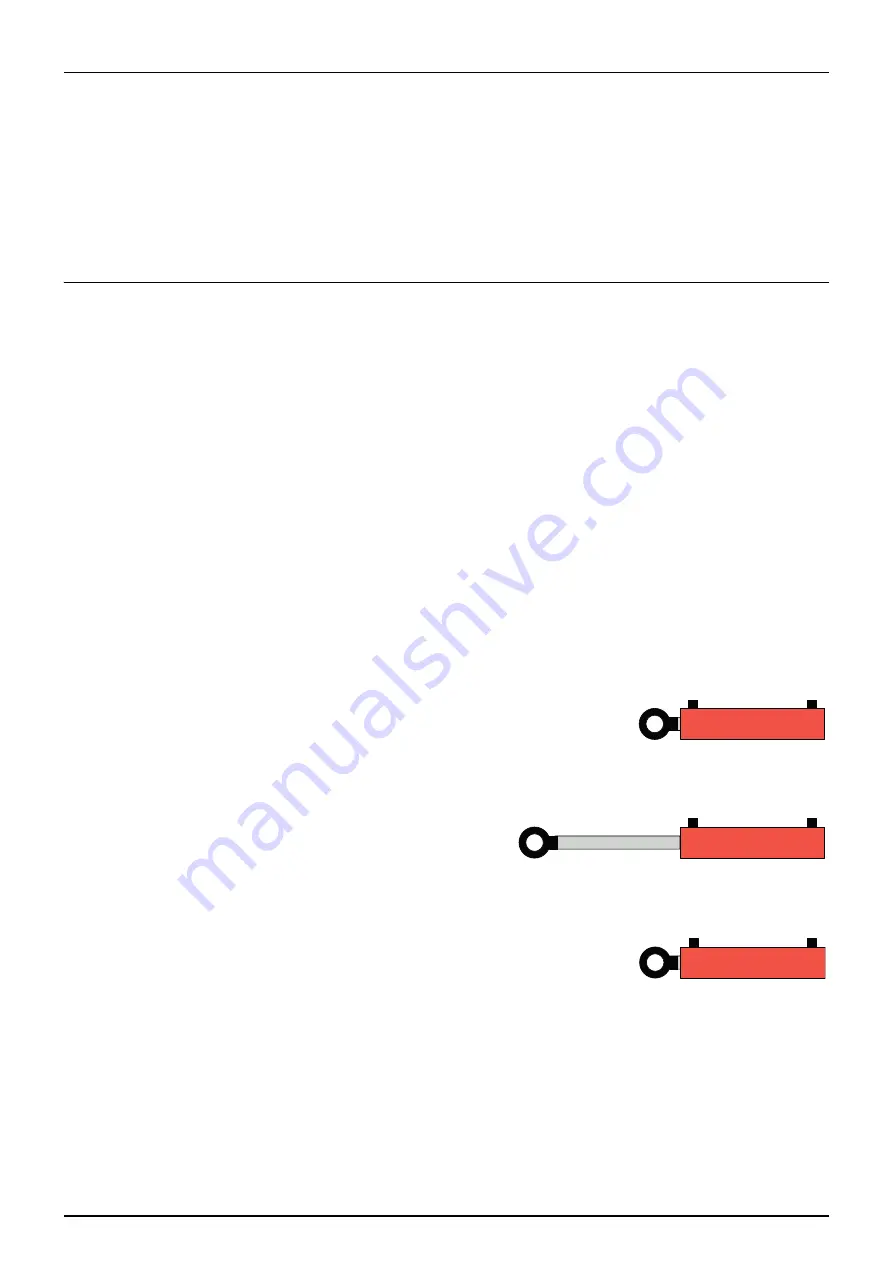

Sequence of Cylinders for Venting

To complete an efficient venting of air in the system, this sequence should be followed.

1.

Left tilt cylinder.

2.

Right tilt cylinder.

Venting Procedure

Follow these steps to complete the venting. Both venting screws or

valves (A and B) are closed to begin with.

1.

Cylinder piston is retracted.

2.

Loosen hydraulic hose connected to (A).

3.

Activate the hydraulic oil pressure and extend the piston fully.

4.

Tighten hose at (A).

5.

Loosen hydraulic hose connected to (B).

6.

Activate the hydraulic oil pressure and retract the piston fully.

7.

Tighten hose at (B).

8.

Repeat steps 3 - 10 a few times until air bubbles are no longer

visible.

9.

Venting is completed for this cylinder.

10.

Check your hydraulic oil level - top up if needed.

€

DANGER! Be careful when operating the cylinders. Make sure that no unauthorized persons are in the working area,

when folding or unfolding the boom! When retracting the pistons into the cylinders, keep fingers, tools and clothes

away from the piston. Risk of getting trapped between moving boom parts or folded boom sections resulting in

severe injuries or death.

μ

ATTENTION! A helping hand is useful to complete the venting procedure.

A

A

B

B

A

B

Summary of Contents for NK MB Series

Page 8: ...1 Identification 8 ...

Page 52: ...3 Description 52 ...

Page 62: ...4 Sprayer Setup 62 ...

Page 84: ...5 Operation 84 ...

Page 87: ...6 Maintenance 87 Boom Lubrication Oiling Plan Lift Lubrication Oiling Plan ...

Page 116: ...9 EC Declaration 116 ...

Page 120: ...Index 120 ...

Page 122: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...