8 - Technical Specifications

113

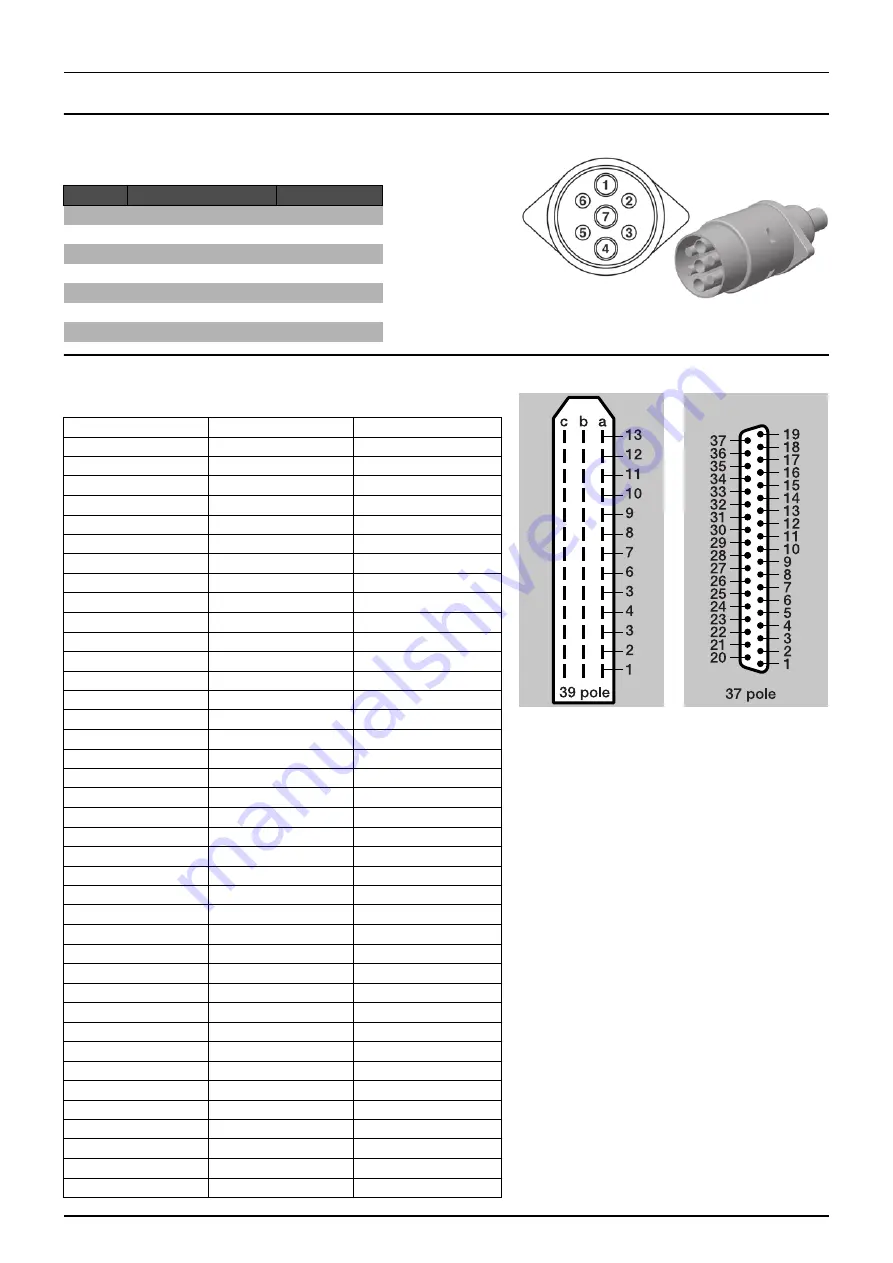

Electrical Connections

Rear Lights

The wiring is in accordance with ISO 1724.

Electrical Connections for SPRAY II

39- or 37-poled plug with cable.

Position

Designation

Wire colour

1

Left direction indicator

Yellow

2

Free (max. 55 W)

Blue

3

Ground

White

4

Right direction indicator

Green

5

Right rear position lamp

Brown

6

Stop lamps

Red

7

Left rear position lamp

Black

39-pole

37-pole

SPRAY II

1a

5

S1+

1b

6

S1-

1c

26

End nozzle L

2a

7

S2+

2b

8

S2-

2c

25

End nozzle R

3a

9

S3+

3b

10

S3-

3c

29

+12V sensor

4a

11

S4+

4b

12

34-

4c

4

PWM 1TX

5a

14

S5+

5b

15

S5-

5c

27

GND

6a

16

S6+

6b

17

S6-

6c

13

Optional 5 Reg. feedback

7a

18

S7+

7b

19

S7-

7c

33

Option 1 4-20mA

8a

37

S8+

8b

36

S8-

8c

32

Option 2 Frq

9a

35

S9+/Air angle 0-5V

9b

34

S9-/Fan speed 0-5V

9c

not connected

Option 3/Tank gauge

10a

21

On/off+

10b

22

On/off-

10c

not connected

PWM Output option

11a

23

P

11b

24

Pressure-

11c

28

Flow

12a

20

Foam blop 0-5V

12b

1

Option 4 Rx

12c

31

Speed

13a

3

FM L

13b

2

FM R

13c

30

Gnd sensor

Summary of Contents for NK MB Series

Page 8: ...1 Identification 8 ...

Page 52: ...3 Description 52 ...

Page 62: ...4 Sprayer Setup 62 ...

Page 84: ...5 Operation 84 ...

Page 87: ...6 Maintenance 87 Boom Lubrication Oiling Plan Lift Lubrication Oiling Plan ...

Page 116: ...9 EC Declaration 116 ...

Page 120: ...Index 120 ...

Page 122: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...