4 - Sprayer Setup

57

Transmission Shaft

Operator Safety

1.

Always read the manufacturer’s instruction book before applying any changes to the transmission shaft!

2.

Always STOP THE ENGINE and remove the ignition key, before carrying out maintenance or repairs to the transmission

shaft or implement.

3.

Always STOP THE ENGINE before attaching the transmission shaft to the tractor power take-off (PTO) - most tractor PTO

shafts can be rotated by hand to facilitate spline alignment, when the engine is stopped.

4.

When attaching the shaft, make sure that the snap lock is FULLY ENGAGED - push and pull the shaft until it locks.

5.

Always keep protection guards and chains intact and make sure that it covers all rotating parts, including CV-joints at

each end of the shaft. Do not use without protection guard.

6.

Do not touch or stand on the transmission shaft, when it is rotating - keep your safety distance at 1.5 meter. Also NEVER

cross over a rotating PTO shaft to reach the other side of the sprayer.

7.

Prevent protection guards from rotating by attaching the chains allowing sufficient slack for turns.

8.

Make sure that protection guards around the tractor PTO and the implement shaft are intact.

€

DANGER! A ROTATING TRANSMISSION SHAFT WITHOUT PROTECTION GUARDS IS FATAL!

PTO Installation

First installation of the transmission shaft is done in the following way:

1.

Attach the sprayer to the tractor and set the sprayer height in the

position with the shortest distance between the tractor and the

sprayer pump PTO shafts.

2.

Stop the engine and remove the ignition key.

3.

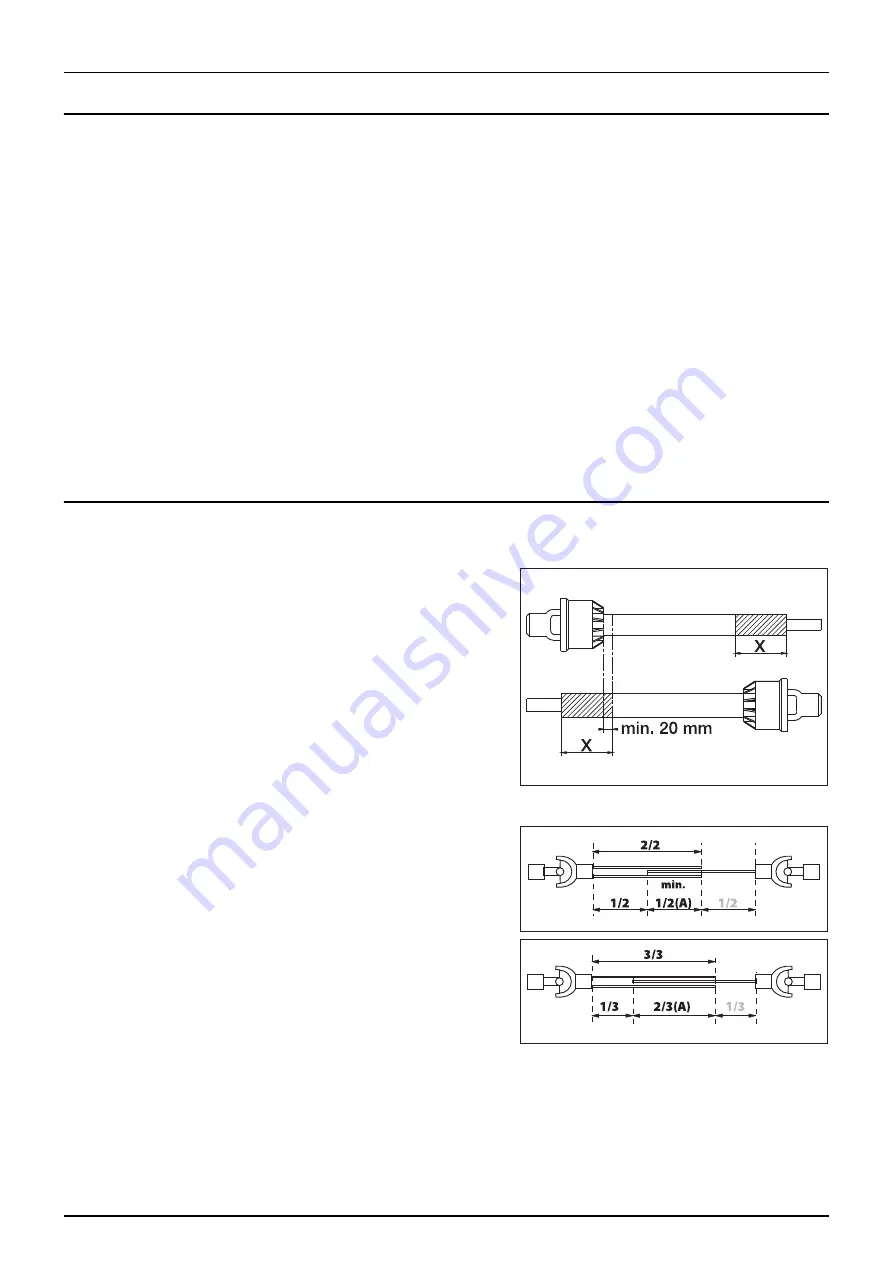

If the transmission shaft needs to be shortened, pull the shaft

apart. Fit the two shaft parts to the tractor and the sprayer pump

and measure how much the shaft needs to be shortened. Also

mark the protection guards with the same length to be shortened.

±

WARNING! Only shorten the shaft if it is absolutely necessary!

The shaft must always have minimum overlap (A) of 1/2 of the sawn

shaft length.

The recommended overlap (A) is 2/3 of the sawn shaft length.

Summary of Contents for NK MB Series

Page 8: ...1 Identification 8 ...

Page 52: ...3 Description 52 ...

Page 62: ...4 Sprayer Setup 62 ...

Page 84: ...5 Operation 84 ...

Page 87: ...6 Maintenance 87 Boom Lubrication Oiling Plan Lift Lubrication Oiling Plan ...

Page 116: ...9 EC Declaration 116 ...

Page 120: ...Index 120 ...

Page 122: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...