20

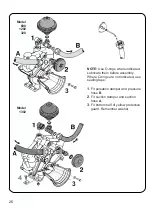

Operational problems

In cases where breakdowns have occurred the same factors always

seem to come into play:

●

Minor leaks on the suction side of the pump will reduce the pump

capacity or stop the suction completely.

●

A clogged suction filter will hinder or prevent suction so that the

pump does not operate satisfactorily.

●

Clogged up nozzle filters will result in increasing pressure at the

pressure gauge but lower pressure at the nozzles.

●

Foreign bodies stuck in the pump valves with the result that these

cannot close tightly against the valve seat. This reduces pump

efficiency.

●

Poorly reassembled pumps, especially diaphragm covers will allow

the pump to suck air resulting in reduced or no capacity.

Therefore ALWAYS check:

1. Suction and nozzle filters are clean.

2. Hoses for leaks and cracks, paying particular attention to suction

hoses.

3. Gaskets and O-rings are present and in good condition.

4. Pressure gauge is in good working order. Correct dosage depends

on it.

5. Operating unit functions properly. Use clean water to check.

Summary of Contents for NL Series

Page 1: ...NL Instruction book 674202 GB 10 1995 www hardi international com ...

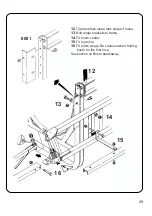

Page 15: ...13 1 X 40 2 A X 12 B X 40 3 X 20 16 17 17 6 10 19 ...

Page 16: ...14 4 X 40 5 X 40 15 15 ...

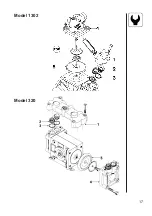

Page 19: ...17 Model 1302 Model 320 ...

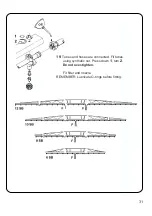

Page 35: ...33 22 Organise hoses it may be necessary to shorten some of them Secure with straps ...

Page 36: ...34 A6 600 foot ...

Page 37: ...35 320 A8 ...

Page 38: ...36 A10 1202 foot ...

Page 39: ...37 1303 foot A12 ...

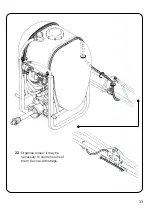

Page 40: ...38 B5 Unit M 70 70 HT ...

Page 41: ...39 Distributor B6 ...

Page 42: ...40 B300 Damper HJ73 ...

Page 43: ...41 SB 6 8 10 m D3 ...

Page 44: ...42 D5 SB 12 m ...

Page 45: ...43 Boom tube 3 8 cap D901 ...

Page 46: ...44 E3 NK 300 400 ...

Page 47: ...45 NL NK 300 400 E102 ...

Page 48: ...46 E103 NL NK 600 800 ...

Page 50: ...48 Notes ...

Page 52: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...