21

Fault

Probable cause

Control / remedy

Air leak on suction.

Air in system.

Suction/nozzle filters

clogged.

Pump valves blocked

or worn.

Defect pressure

gauge.

Filters clogging.

Nozzles worn.

Tank is airtight.

Nozzle filters

beginging to clog.

Air is being sucked

into system.

Excessive liquid

agitation.

Damaged diaphragm.

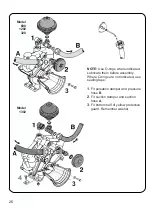

Check if red suction lid/O-ring are

sealing.

Check suction tube and fittings.

Check tightness of pump diaphragm

and valve covers.

Fill suction hose with water for initial

prime.

Clean filters.

Check yellow suction pipe is not

obstructed or placed too near the

tank bottom.

Check for obstructions and wear.

Check for dirt at inlet of gauge.

Clean all filters. Fill with cleaner

water.

Check flow rate and replace nozzles

if it exceeds 10%.

Check vent is clear.

Clean all filters.

Check tightness / gaskets / O-rings

of all fittings on suction side.

Reduce pump r/min.

Use foam damping addative.

Replace. See Changing of valves

and diaghragms.

No spray from

boom when

turned on.

Lack of

pressure.

Pressure

dropping.

Pressure

increasing

Formation of

foam.

Liquid leaks

from bottom of

pump.

Liquid system

Summary of Contents for NL Series

Page 1: ...NL Instruction book 674202 GB 10 1995 www hardi international com ...

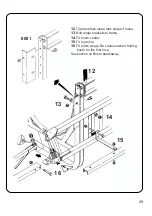

Page 15: ...13 1 X 40 2 A X 12 B X 40 3 X 20 16 17 17 6 10 19 ...

Page 16: ...14 4 X 40 5 X 40 15 15 ...

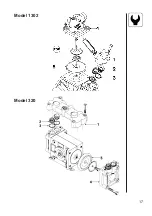

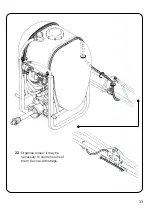

Page 19: ...17 Model 1302 Model 320 ...

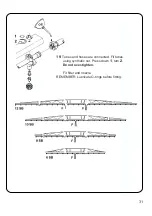

Page 35: ...33 22 Organise hoses it may be necessary to shorten some of them Secure with straps ...

Page 36: ...34 A6 600 foot ...

Page 37: ...35 320 A8 ...

Page 38: ...36 A10 1202 foot ...

Page 39: ...37 1303 foot A12 ...

Page 40: ...38 B5 Unit M 70 70 HT ...

Page 41: ...39 Distributor B6 ...

Page 42: ...40 B300 Damper HJ73 ...

Page 43: ...41 SB 6 8 10 m D3 ...

Page 44: ...42 D5 SB 12 m ...

Page 45: ...43 Boom tube 3 8 cap D901 ...

Page 46: ...44 E3 NK 300 400 ...

Page 47: ...45 NL NK 300 400 E102 ...

Page 48: ...46 E103 NL NK 600 800 ...

Page 50: ...48 Notes ...

Page 52: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...