5 - Operation

53

Parking the sprayer

To avoid spot contamination the sprayer should always be parked at either the washing/filling place or under roof. This avoid

rainfall to flush down chemical residues from the sprayer's surfaces.

•

Parking at the washing/filling location will retain residues.

•

Always park the machine out of reach of children, animals or unauthorized persons.

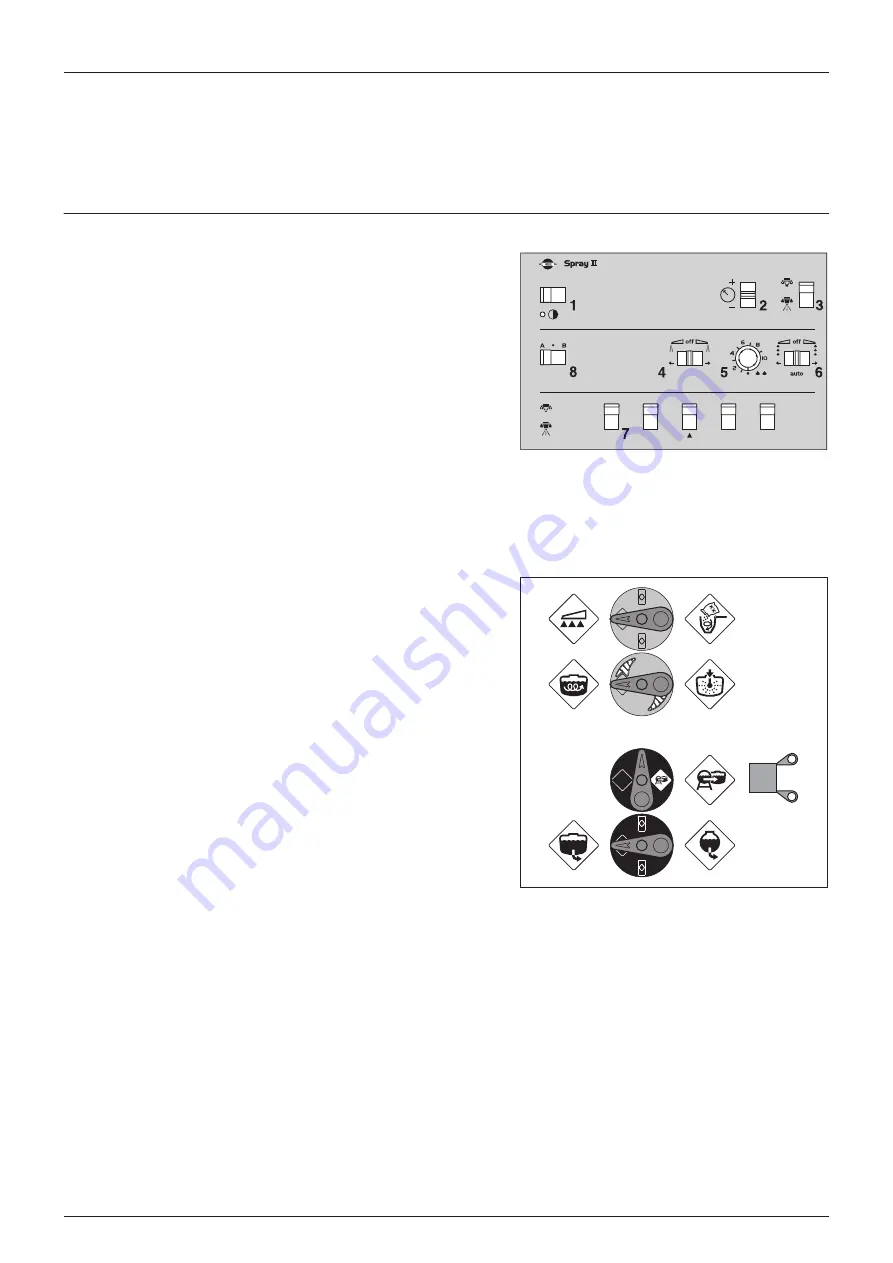

Operating the control unit while spraying

The switches of the spray control unit control the following functions:

1.

Power ON/OFF. Turns the spraybox power on or off.

2.

Spray pressure regulation. Regulates the main spray pressure.

3.

Main valve ON/OFF. Turns all sections on or off. Lever up is OFF and

down is ON.

4.

End nozzle (Left/OFF/Right). If end nozzles are fitted, they can be

turned on for each side. Middle position is OFF.

5.

Foam marker blob interval. Regulates the blob interval for the

optional foam marker.

6.

Foam marker (Left/OFF/Right). Turns the optional foam marker on for each side. Middle position is OFF.

7.

Section valves. Turns single sections on or off. Lever up is OFF and down is ON.

8.

Optional function (A/OFF/B). If extra equipment is added, it can be controlled from here. Middle position is OFF.

•

In order to close the entire boom, switch main ON/OFF (3) to OFF

position. This returns the pump output to the tank through the

return system. The diaphragm Non-drip valves ensure

instantaneous closing of all nozzles.

•

In order to close one or more sections of the boom, switch the

relevant distribution valve (7) to off position (upwards). The

pressure equalisation ensures that the pressure does not rise in the

sections that remain open.

•

On the sprayer the suction valve should be turned toward “Suction

from Main tank” and the pressure valve should be turned toward

“Spraying”. Turn the agitation valve to “Agitation” if necessary.

Summary of Contents for RANGER EAGLE

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 26: ...3 Description 26 ...

Page 40: ...4 Sprayer setup 40 ...

Page 60: ...5 Operation 60 ...

Page 84: ...6 Maintenance 84 ...

Page 95: ...8 Technical specifications 95 Charts Boom hydraulic Z Boom hydraulic Y ...

Page 96: ...8 Technical specifications 96 ...

Page 100: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...