6 - Maintenance

67

250 hours service - Air brake filters (optional)

1.

Clean the area around air filter(s) and disconnect air hose from the

tractor.

2.

Hold one hand under the filter housing, and pull out the retainer

clip (A). The filter cartridge assembly will be pushed out by the

springs inside the filter housing.

3.

Clean the filter cartridge. Use water and an appropriate detergent

or compressed air.

4.

Dry the parts and reinstall in the order shown. The O-ring should

be lightly lubricated with silicone grease before installation.

±

WARNING! Never dismantle the filter without having the tractor

disconnected and pressure relieved.

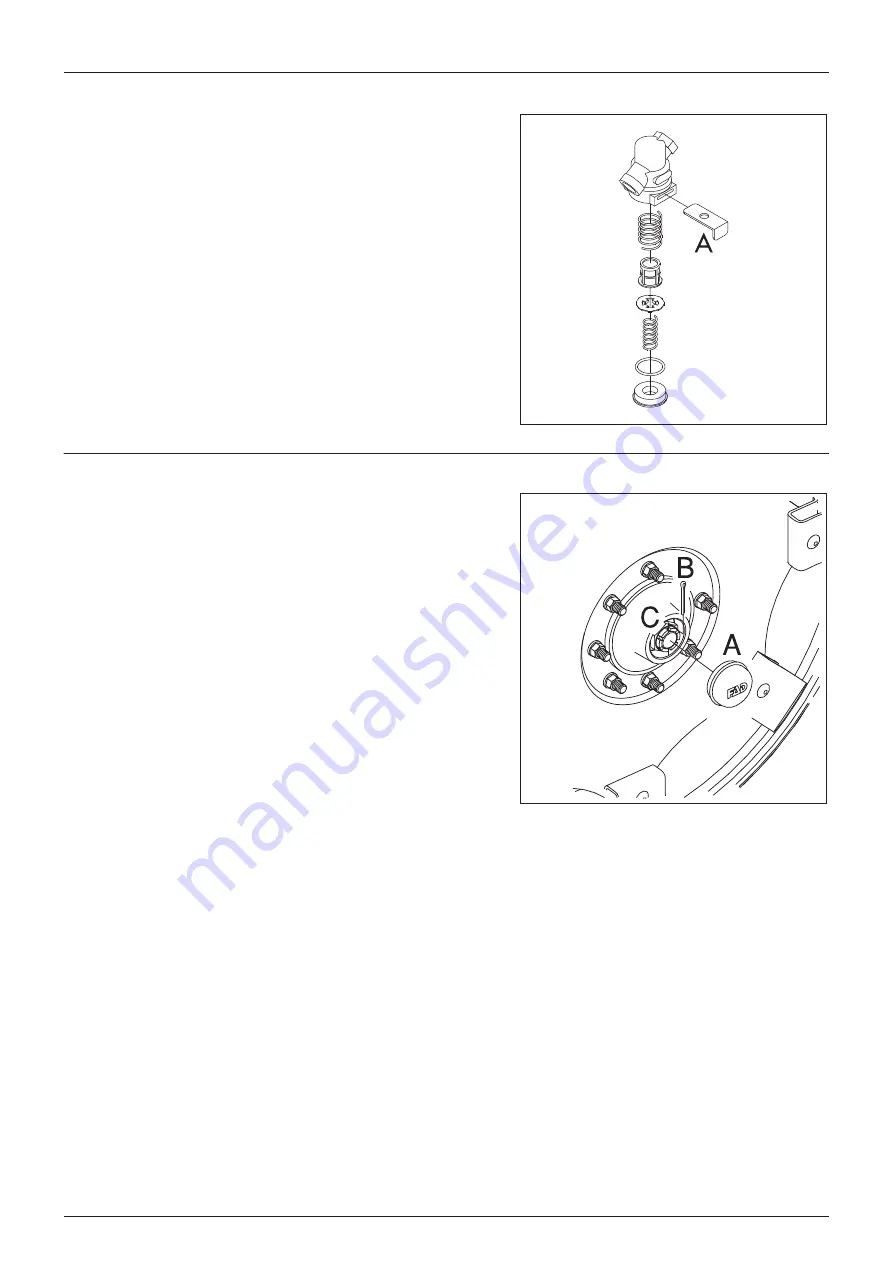

250 hours service - Wheel bearings

Check for play in the wheel bearings:

1.

Place stop wedges in front of and behind LH wheel and jack up RH

wheel.

2.

Rock the RH wheel to discover possible play in the bearings.

3.

If any play, support the wheel axle to prevent the trailer from falling

down from the jack.

4.

Remove hub cap (A) and cotter pin (B). Turn the wheel and tighten

the castellated nut (C) until a slight resistance in the wheel rotation

is felt.

5.

Loosen the castellated nut until the first notch - horizontal or

vertical - is aligned with the cotter pin hole in the shaft.

6.

Fit a new cotter pin and bend it.

7.

Fit the hub cap to the hub again.

8.

Repeat the procedure on LH wheel.

÷

NOTE! Some hub caps are attached with screws. Make sure the seal is intact or replace if worn!

Summary of Contents for RANGER EAGLE

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 26: ...3 Description 26 ...

Page 40: ...4 Sprayer setup 40 ...

Page 60: ...5 Operation 60 ...

Page 84: ...6 Maintenance 84 ...

Page 95: ...8 Technical specifications 95 Charts Boom hydraulic Z Boom hydraulic Y ...

Page 96: ...8 Technical specifications 96 ...

Page 100: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...