6 - Maintenance

63

Service and Maintenance intervals

10 hours service - Spraying circuit

Fill with clean water, operate all functions and check for leaks using higher spray pressure than normal. Check nozzle spray

patterns visually using clean water.

10 hours service - Nozzle filters

Check and clean.

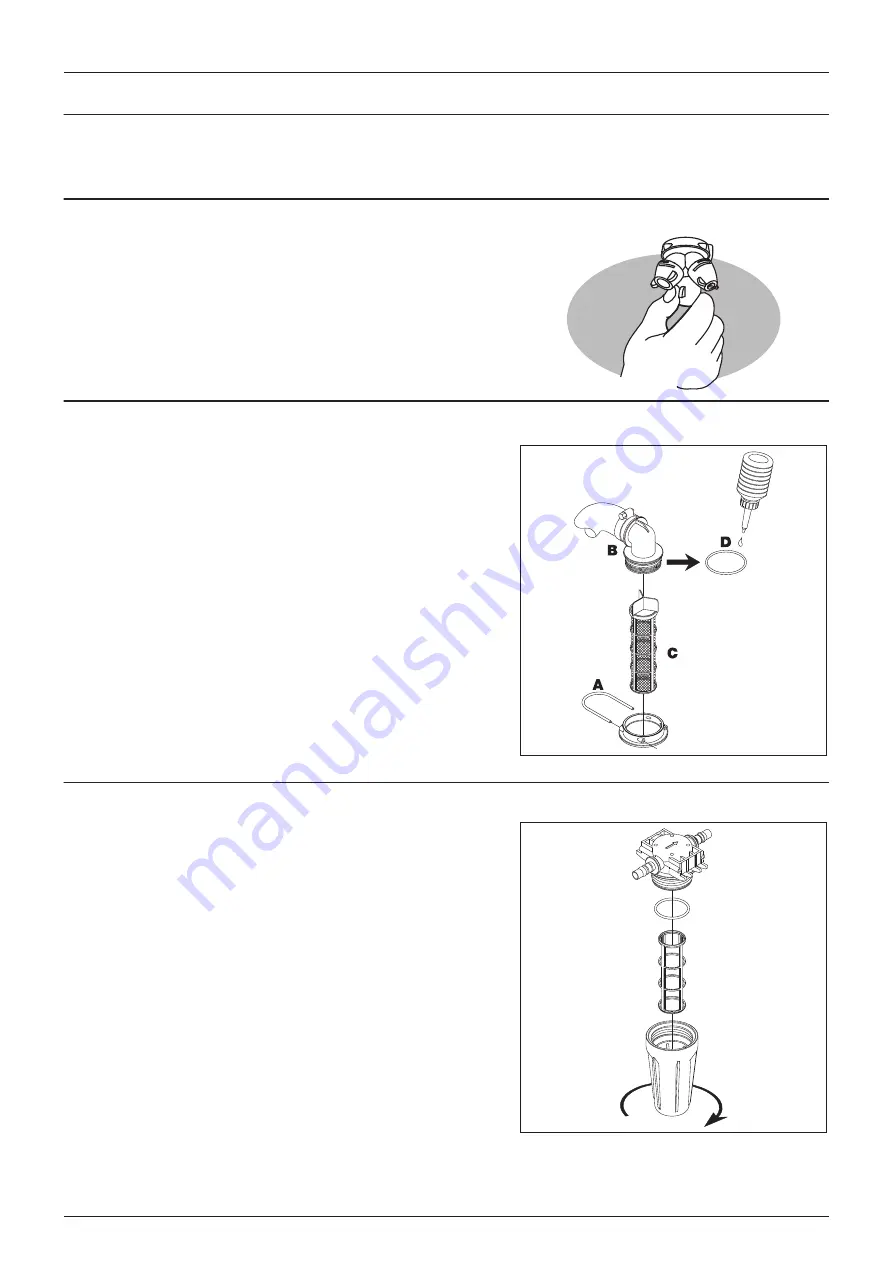

10 hours service - Suction filter

To service the suction filter:

1.

Pull out the steel clip (A).

2.

Lift the suction hose fitting (B) from housing.

3.

Filter guide and filter (C) can now be removed.

To reassemble:

4.

Press the guide onto filter end.

5.

Place the filter into housing with guide facing up.

6.

Ensure the O-ring (D) on the hose fitting is in good condition and

lubricated.

7.

Refit the suction hose (B) and steel clip (A).

±

WARNING! Always wear protective clothing and gloves before

opening the filter!

10 hours service - In-Line filter (optional)

If the boom is equipped with In-Line Filters, unscrew the filter bowl to

inspect and clean the filter. When reassembling, the O-ring should be

greased.

Alternative filter meshes are available. See section on Technical

specifications - Filters and nozzles.

±

WARNING! Be careful not to splash out liquid when unscrewing

the filter bowl.

±

WARNING! Always wear protective clothing and gloves before

opening the filter!

Summary of Contents for RANGER EAGLE

Page 8: ...1 EC Declaration 8 ...

Page 12: ...2 Safety notes 12 ...

Page 26: ...3 Description 26 ...

Page 40: ...4 Sprayer setup 40 ...

Page 60: ...5 Operation 60 ...

Page 84: ...6 Maintenance 84 ...

Page 95: ...8 Technical specifications 95 Charts Boom hydraulic Z Boom hydraulic Y ...

Page 96: ...8 Technical specifications 96 ...

Page 100: ...HARDI INTERNATIONAL A S Helgeshøj Allé 38 DK 2630 Taastrup DENMARK ...