5 - Operation

101

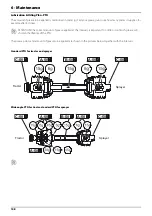

Rinsing when main tank is not empty

Rinsing the pump, operating units, spray lines, etc. in case of stop in spraying (e.g. because of rain), before main tank is empty.

Cleaning of the liquid system:

1.

Turn suction valve towards

. (Keep pressure valve in

-position).

2.

Close AgitationValve (no agitation).

3.

Engage the pump. Set the pump speed to approximately 300 rpm and increase the spraying pressure to 6 bar. Spray

the water from the rinsing tank into the field, until all nozzle tubes and nozzles have been flushed with clean water.

4.

Disengage the pump.

μ

ATTENTION! It is advisable to increase the forward speed (double, if possible) and reduce the spraying pressure to 1.5

bar, when spraying diluted remaining liquid in the field just sprayed.

Cleaning the sprayer on the outside

1.

Turn suction valve towards

and pressure valve towards ”Internal Tank Cleaning”.

2.

When another 1/3 of the contents in the rinsing tank is used, turn the suction valve towards

. Adjust the spraying

pressure to 8 - 10 bar.

3.

Turn pressure Agitation valve towards “External Cleaning Device” and wash the sprayer with the cleaning device

located on sprayer’s right side.

4.

Disengage pump again.

μ

ATTENTION! If the sprayer is cleaned with a high pressure washer, lubrication of the entire machine is recommended.

Outside Cleaning - Use of External Cleaning Device

Use the External Cleaning Device to wash everything on the outside of the sprayer.

1.

Unroll the hose from the reel.

2.

Engage pump speed to approximately 250 rpm.

3.

Turn the suction valve towards

and pressure valve towards

or not unused function.

4.

Turn valve towards

“External Cleaning Device” and clean the

sprayer.

5.

After cleaning, close the valve again.

6.

Roll the hose on the reel again.

μ

ATTENTION! If the safety valve is activated, then lower the PTO

speed to minimize the amount of rinsing water being lost into

the main tank.

μ

ATTENTION! If the sprayer is cleaned with a high pressure washer, lubrication of the entire machine is recommended.

Summary of Contents for RANGER PRO VH

Page 4: ...1 EU Declaration 4 ...

Page 10: ...Table of Contents 6 ...

Page 108: ...5 Operation 104 ...

Page 111: ...6 Maintenance 107 Boom Lubrication Oiling Plan Lubrication Oiling Plan Trailer Paralift ...

Page 142: ...6 Maintenance 138 ...

Page 164: ...Index 160 ...

Page 166: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...