5 - Operation

102

BoomFlush

When having the BoomFlush valves fitted to the end(s) of boom piping, the cleaning procedure is as follows:

1.

Follow the cleaning procedure to clean the sprayer the first two times.

2.

Open all BoomFlush valves by hand.

3.

Continue the cleaning procedure to clean the sprayer for the third time.

4.

Close BoomFlush valves.

±

WARNING! To prevent contamination of the soil, the BoomFlush valves must only be opened at the last step of

cleaning!

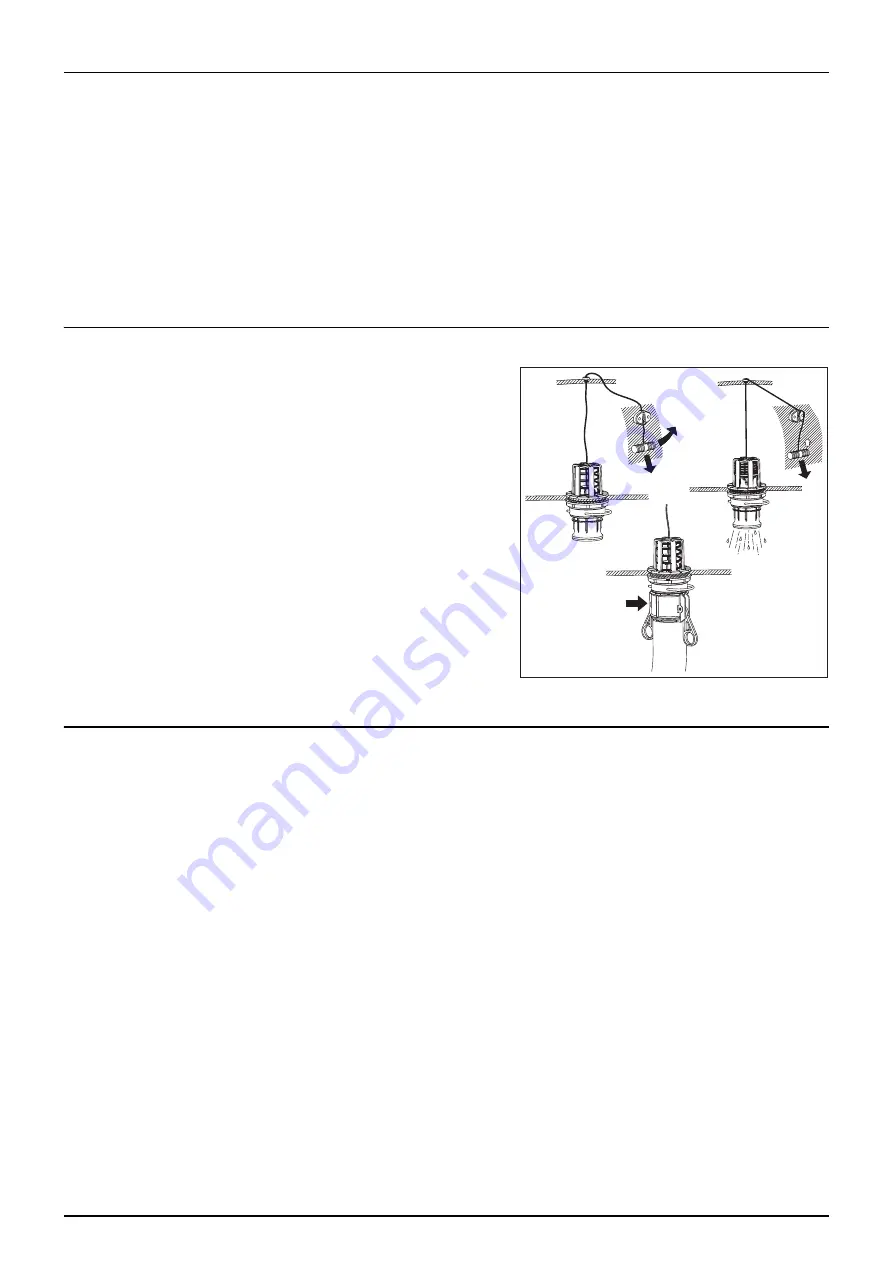

Using the Drain Valve

The drain valve is operated from the platform just beside the main tank

lid.

1.

Pull the string to open the drain valve.

2.

The valve is spring-loaded, but can be kept open by pulling the

string upwards in the V-shaped slit.

3.

To release, pull the string downward and the valve will close

automatically.

If draining residues, e.g. liquid fertilizer into a reservoir, a snap coupler

with hose can rapidly be connected to the drain valve, and the liquid is

safely drained.

Technical Residue

An amount of spray liquid will inevitably remain in the system. It cannot be sprayed properly on the crop, as the pump takes

in air, when the tank is just about empty.

This technical residue is defined as the remaining amount of liquid in the system, when the first clear pressure drop appears

on the pressure gauge.

The residual dilutable volume is approx. 17 litres. See the section “Technical Specifications” for more details.

The residues in the tank should be diluted immediately in a ratio of 1:10 with clean water. Afterwards it should be sprayed

on the crop just sprayed with increased driving speed.

In addition, also pump, linkage and armature can be separately rinsed with water from the rinsing tank. However, it must be

ensured that the liquid in the spray lines are in unchanged concentration. Therefore there should be an untreated field area

available to spray this liquid out.

Follow national regulations when disposing of chemical residues.

Summary of Contents for RANGER PRO VH

Page 4: ...1 EU Declaration 4 ...

Page 10: ...Table of Contents 6 ...

Page 108: ...5 Operation 104 ...

Page 111: ...6 Maintenance 107 Boom Lubrication Oiling Plan Lubrication Oiling Plan Trailer Paralift ...

Page 142: ...6 Maintenance 138 ...

Page 164: ...Index 160 ...

Page 166: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...