4 - Sprayer Setup

68

Track Width, Axles and Wheels

Procedure for Altering the Track Width

The track width of the sprayer can be altered in steps.

11.

Measure the current track width (centre of right tyre to centre of

left tyre). Each side must be extended or retracted half the desired

alteration.

12.

Connect the sprayer to the tractor and engage the tractor parking

brake.

13.

Place stop wedges in front of and behind the right wheel. Jack up

the left wheel and support with trestles.

14.

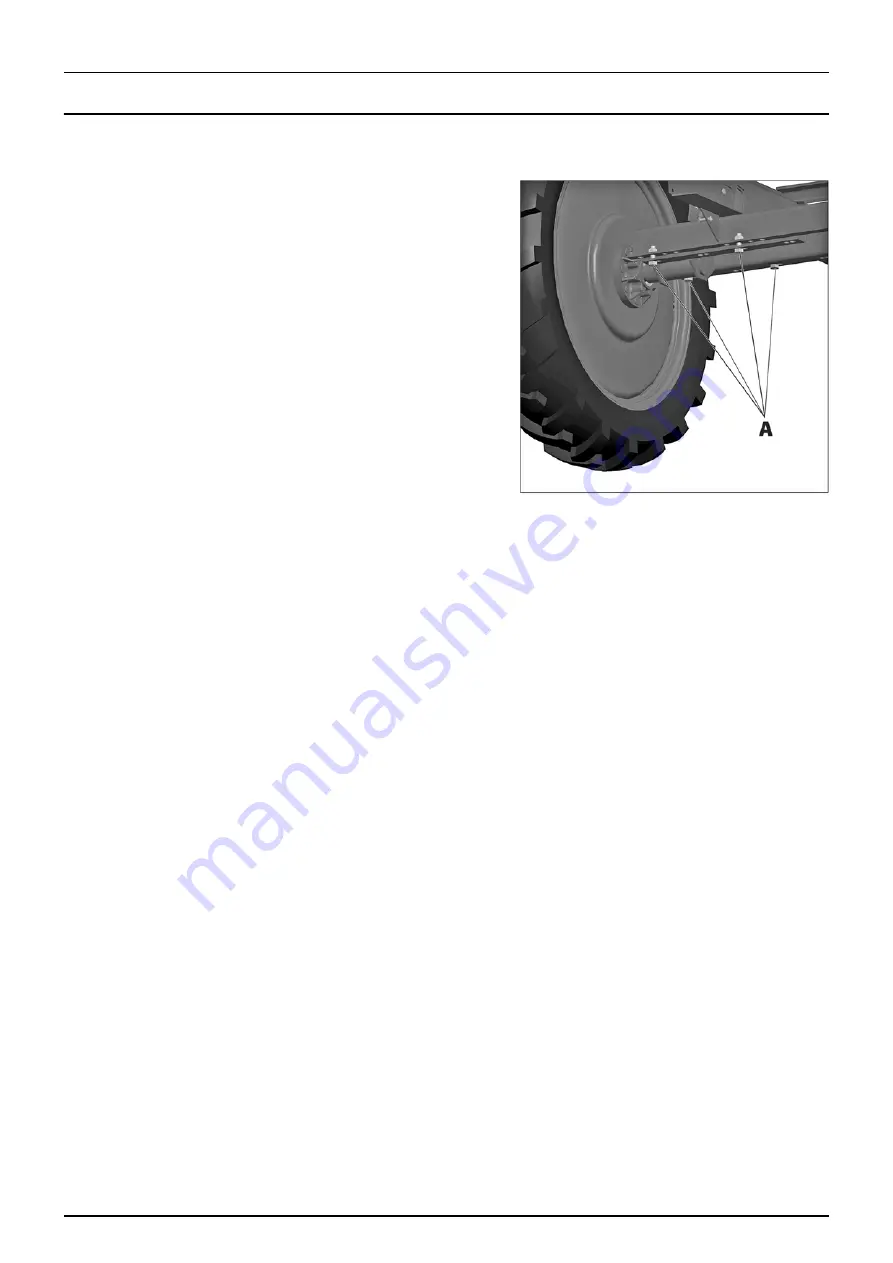

Loosen the bolts (A) for left wheel axle.

15.

If a handbrake is installed, loosen the pointed screw on the brake

operating arm.

16.

Extend or retract the axle. A sack barrow and a rod will facilitate the

operation.

17.

Tighten the clamp bolts (A) with a torque of 250 Nm. Lower the

wheel to the ground.

18.

Repeat the procedure on the right wheel.

19.

Check if the distance from centre tyre to centre of rear frame is equal at the right and left side.

20.

Retighten bolts and wheel bolts to the specified torque after 8 working hours.

μ

ATTENTION! The wider the track width, the better the stability of the sprayer. Use the widest possible track width.

±

WARNING! Place the jack under the axle and lift the wheel to remove load from the clamps before tightening the

clamp bolts to the specified torque.

Summary of Contents for RANGER PRO VH

Page 4: ...1 EU Declaration 4 ...

Page 10: ...Table of Contents 6 ...

Page 108: ...5 Operation 104 ...

Page 111: ...6 Maintenance 107 Boom Lubrication Oiling Plan Lubrication Oiling Plan Trailer Paralift ...

Page 142: ...6 Maintenance 138 ...

Page 164: ...Index 160 ...

Page 166: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...