5 - Operation

91

•

In order to shut all nozzles, set the main ON/OFF (3) to OFF

position. This returns the pump output to the tank through the

return system. The diaphragm non-drip valves ensure

instantaneous closing of all nozzles.

•

In order to close one or more sections of the boom, switch the

relevant distribution valve (8) to off position (upwards). The

pressure equalization (DF4, if installed) ensures that the pressure

does not rise in the sections, which remain open.

•

On the sprayer, the suction valve should be turned towards

“suction from main tank” and the pressure valve should be turned

towards “spraying”. Turn the agitation valve to “agitation” if needed.

Summary of Contents for RANGER PRO VH

Page 4: ...1 EU Declaration 4 ...

Page 10: ...Table of Contents 6 ...

Page 108: ...5 Operation 104 ...

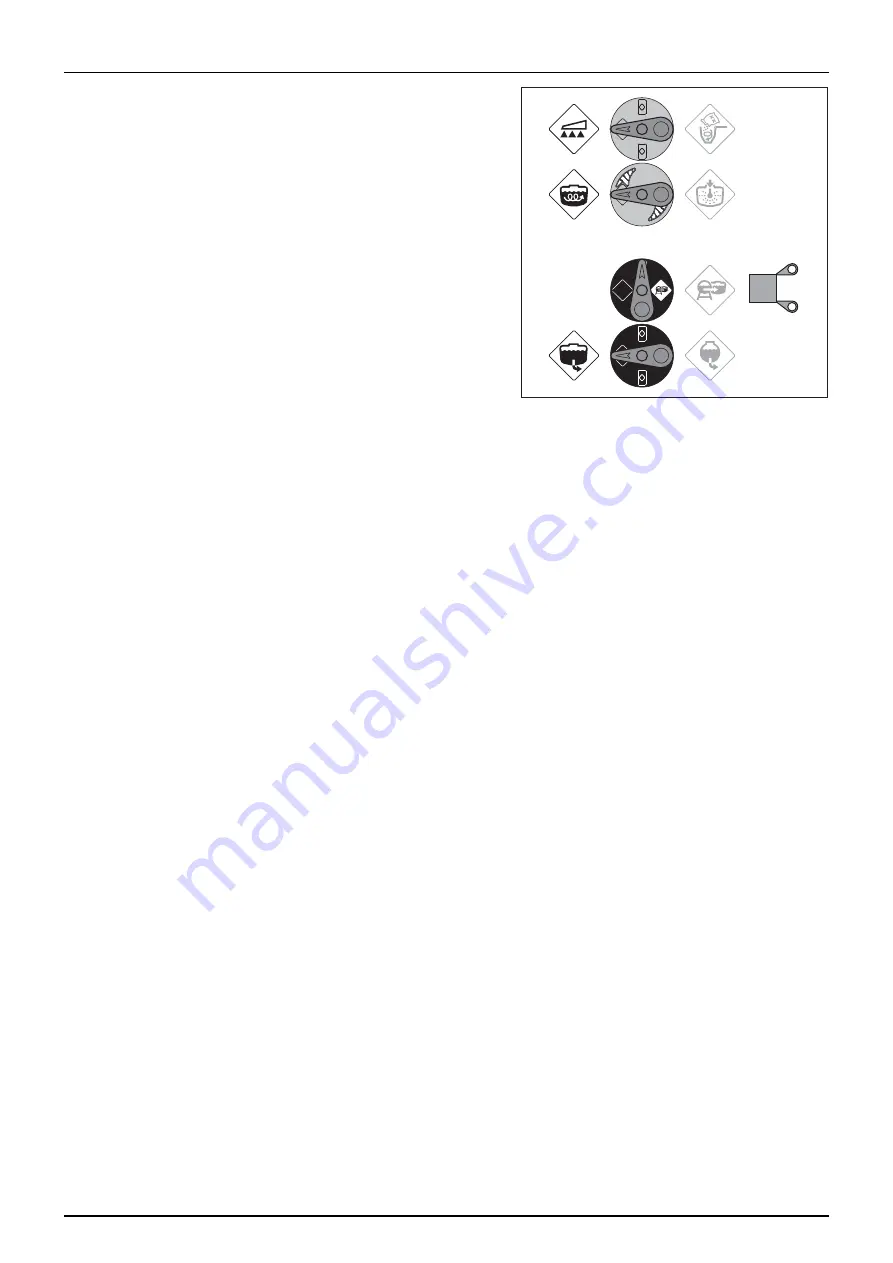

Page 111: ...6 Maintenance 107 Boom Lubrication Oiling Plan Lubrication Oiling Plan Trailer Paralift ...

Page 142: ...6 Maintenance 138 ...

Page 164: ...Index 160 ...

Page 166: ...HARDI INTERNATIONAL A S Herthadalvej 10 DK 4840 Nørre Alslev DENMARK ...