5 -

O

pe

r

a

tion

5.8

A

dj

ust

me

nt

o

f

E

VC

o

pe

r

a

tin

g

unit

Before spraying, adjust the EVC operating unit using clean water (with-

out chemicals).

1. Choose the correct nozzle for the spray job by turning the TRIPLET

nozzle bodies. Make sure that all nozzles are the same type and capaci-

ty. See the “Spray Technique” book.

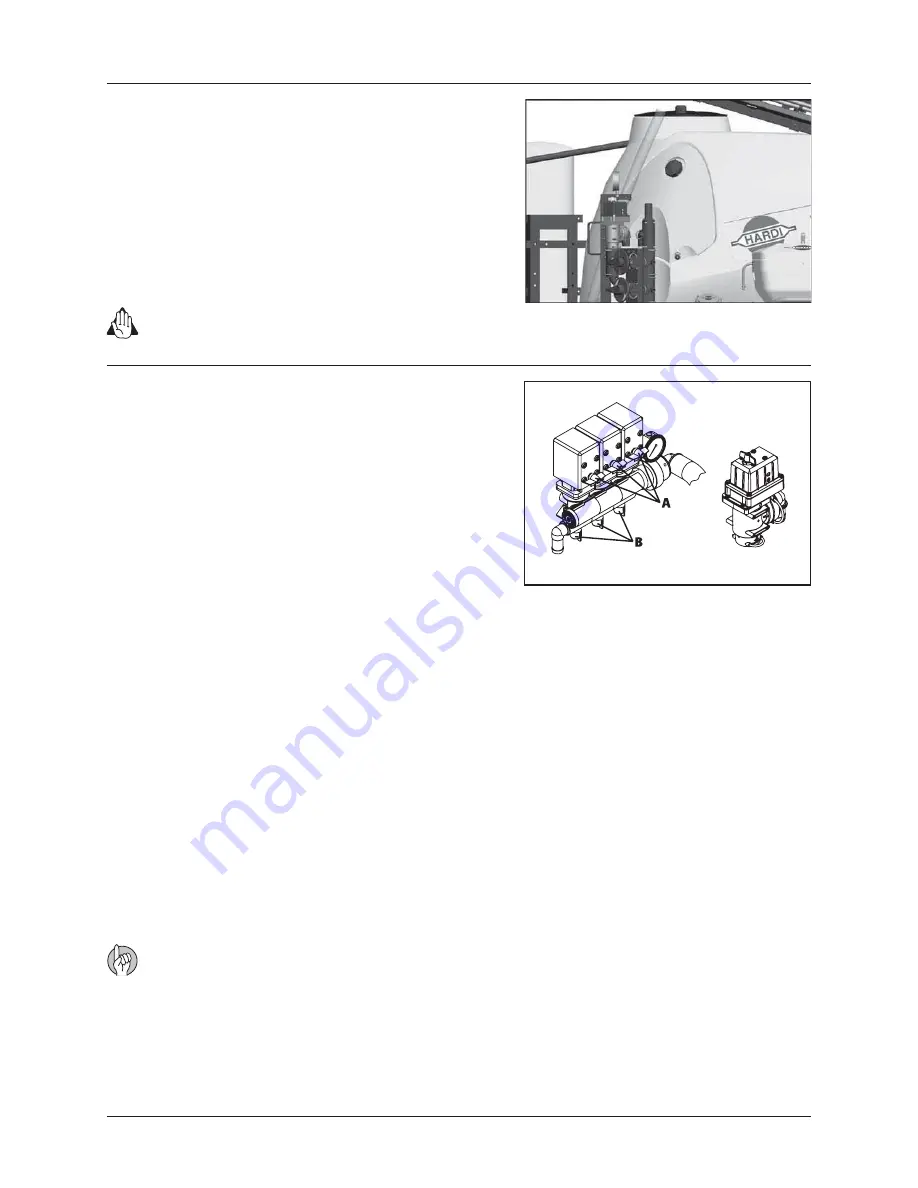

2. Make sure all distribution valves (A) are turned on.

3. Set pressure regulation valve to minimum pressure (activate pressure

regulation switch “down” until emergency handle stops rotating).

4. Put the tractor in neutral and adjust the P.T.O. revolutions to the num-

ber of revolutions that will typically be used while spraying. Remember

the number of revolutions on the P.T.O. must be kept between 300-600

r.p.m. (540 r.p.m. pump) or 650-1100 rpm (1000 r.p.m. pump).

5. Activate pressure regulation switch “up” until the required spraying

pressure is shown on the pressure gauge.

Adjustment of pressure equalization:

1. Disconnect power to the control box to allow for manual operation of

the boom distribution valves. Adjustments will be made one section at

a time until all valves have been adjusted.

2. Note the pressure on the pressure gauge. This reading will be used

throughout the adjustment.

3. Manually close one of the distribution valves by turning the green

handle (A).

4. Turn the adjusting screw (B), under the valve just closed, until the

pressure gauge again shows the same pressure as before (clockwise for

higher pressure, counterclockwise for lower pressure).

5. Turn the distribution valve (A) back on.

6. Adjust the other sections of the distribution valve in the same way.

WARNING! Although the clean water tank is only filled with

clean water, this water must never be used for drinking.

A clean water tank is integrated into the front left corner of the main

tank (behind the MANIFOLD system). It is accessed for filling at the

sprayer’s left side when entering the platform. Remove tank lid, fill

with clean water and replace tank lid.

For use of water, turn the ball valve lever to open tap. The ball valve

is located at the bottom of the clean water tank on sprayer’s left

side. The water from this tank is for hand washing, cleaning of

clogged nozzles, etc. Only fill the clean water tank with clean water.

Capacity: 4.8 gal. (18 liters).

F

i

ll

in

g

o

f

c

lea

n

wa

t

e

r

t

a

nk

ATTENTION! HEREAFTER ADJUSTMENT OF PRESSURE EQUALIZATION WILL ONLY BE NEEDED WHEN:

1. YOU CHANGE TO NOZZLES WITH OTHER CAPACITIES

2. THE NOZZLE OUTPUT INCREASES AS THE NOZZLES WEAR

Summary of Contents for Ranger Series

Page 1: ...GLOBAL RANGER Instruction book 67021203 Version 1 00 US 07 2006 ...

Page 2: ......

Page 4: ......

Page 10: ...1 Welcome 1 2 ...

Page 14: ...2 Safety notes 2 4 ...

Page 54: ...6 Maintenance 6 2 Trailer lubrication oiling plan ...

Page 70: ...6 Maintenance 6 18 ...

Page 82: ...8 Technical specifications 8 8 Boom hydraulics HZ Boom hydraulics HY Charts ...

Page 83: ...8 Technical specifications 8 9 Boom hydraulics DH ...

Page 84: ...8 Technical specifications 8 10 ...

Page 87: ......