74

5 - Operation

Adjusting the BK/2 Operating Unit

ATTENTION! It is very important that the operating unit is well

adjusted. Before using the equipment for the first time, it is

necessary to adjust the constant pressure valves at each section

valve.

During this procedure, the individual return capacity of each section

is adjusted, so that it returns the same amount of liquid that would

normally be sprayed through all the nozzles at the section when open.

This avoids variations in pressure when one or both sections are shut.

The adjustment procedure is the following:

1. Open both sections via the lever taps.

2. Set the pressure at, for example, 3 bar.

3. Close one of the Sections.

4. Adjust the constant pressure valve of the closed section valve until the pressure gauge indicates 3 bar again.

5. Open the section valve again and repeat this procedure for the other section valve.

6. Verify the adjustment by opening both sections at the same time or one by one. If the operating unit is correctly

adjusted the pressure always remains unchanged.

ATTENTION! It is recommended to carry out this adjustment as close to the intended working pressure as

possible.

ATTENTION! Carry out this adjustment every so often as somebody may accidentally change the position of the

pressure equalisation valve

ATTENTION! once the pressure adjustment has been performed, it only needs readjustment when:

1. Another nozzle with a different capacity is used.

2. The nozzle output has increased due to wear.

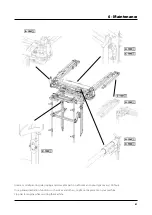

MC/2 operating unit

This high-pressure manual operating unit is used in configurations with

piston or diaphragm pumps.

It consists of a pressure valve with a built-in pressure gauge.

To adjust the pressure, turn the black handle. To increase the pressure,

turn the handle clockwise. To decrease pressure, turn it anti-clockwise.

The spray can be controled from the tractor using the two remote

levers.

Each lever controls one section valve. You can select one section, two

sections or no sections open.

A

Summary of Contents for ZENIT 400

Page 2: ......

Page 4: ......

Page 10: ...6...

Page 117: ......

Page 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...