76

5 - Operation

Filling/washing location requirements

When filling the sprayer with chemicals and water it is important to avoid spot contamination by spray chemicals in

order to protect the subsoil water resources.

A. If the mistblower is always filled at the same place, a special filling/washing location should be established. This

should have a hard, liquid-impenetrable surface (e.g. concrete) securing against seepage and edges securing

against run-off to the surrounding areas. The place should be drained to an adequate receptacle (e.g. slurry tank

or similar).

Any spillage or washings should be retained and diluted in order to be distributed on a larger area to ensure

minimal environmental impact and avoid build-up of larger chemical concentrations at one spot.

If no other requirements of distances exist, the following general recommendation of distance could be used. Not

closer than:

1) 50 metres from public water supplies for drinking purposes,

2) 25 metres from non-public water supplies for drinking purposes, treatment sumps and cesspools of drainage

systems, and

3) 50 metres from surface water (watercourses, lakes and coastal waters) and from nature reserves.

B. Alternatively the sprayer can be filled in the field where the spraying is to take place. If so, choose a different

location for each refilling.

If no other requirements of distances exist, the filling should not be established closer than:

1) 300 metres from public or non-public water supplies for drinking purposes and

2) 50 metres from surface water (watercourses, lakes and coastal waters), treatment sumps, cesspools of drainage

systems, and nature reserves.

ATTENTION! Legislation and requirements vary from country to country. Always follow local legislation in force at

any time.

NOTE! It is the responsibility of the sprayer owner/operator to comply with all relevant legislation. HARDI cannot

undertake any responsibilities for incorrect operation and use.

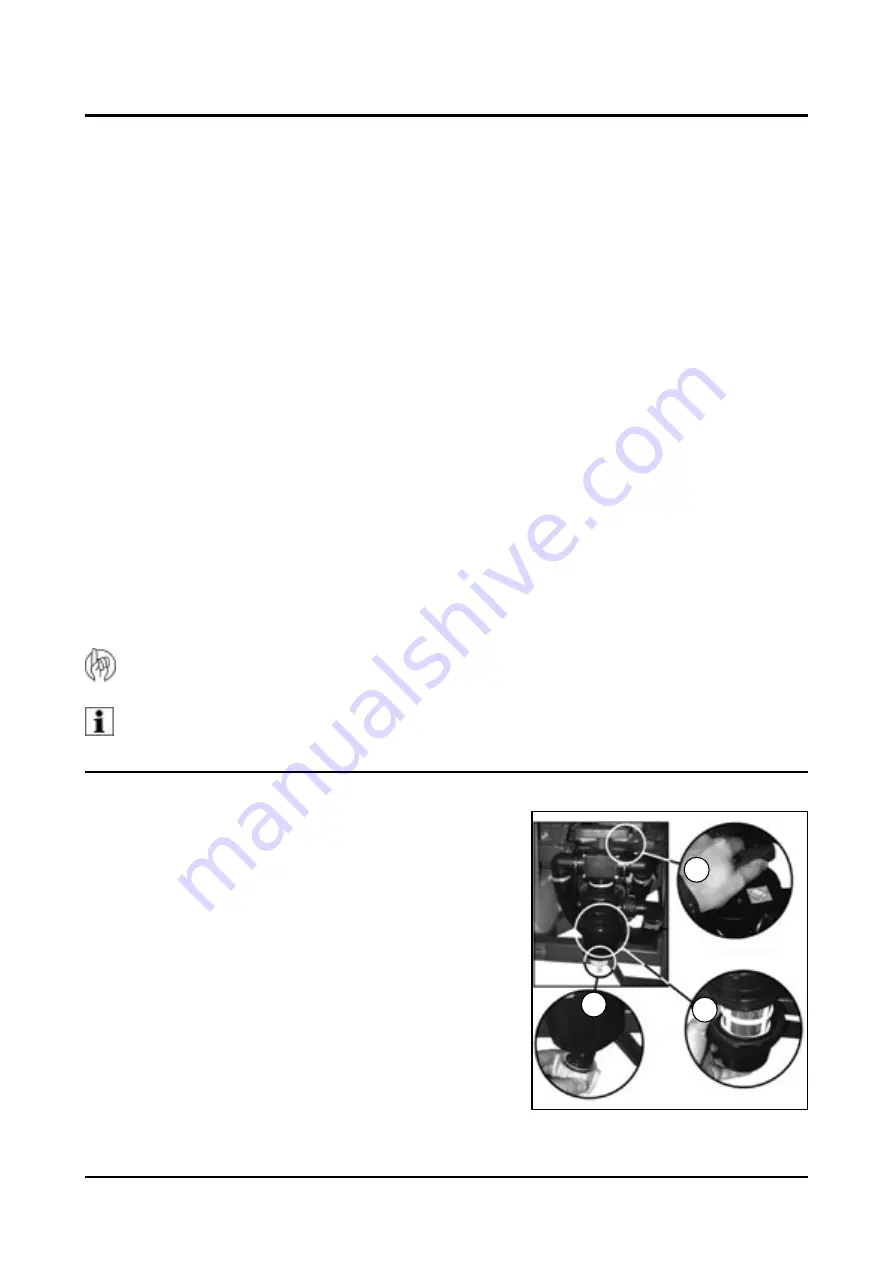

Suction Filter

This is located on the bottom left-hand side of the equipment and is

easy to access. To clean the filter you should do as follows:

1. Close the three-way valve.

2. Shut the valve of the filter (A) before dismantling the filter.

3. Undo the filter housing (B) to access the filter screen.

4. Clean the filter (C) and assemble in reverse order.

The filter should be cleaned after each spray job while remining spray

liquid is still agitated. This will prevent operational problems caused by

sediments.

A

B

C

Summary of Contents for ZENIT 400

Page 2: ......

Page 4: ......

Page 10: ...6...

Page 117: ......

Page 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...