77

5 - Operation

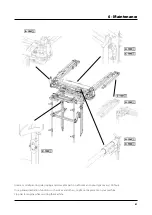

Nozzles

The standard nozzle can be closed individually by turning them 90º.

When open the direction can be adjusted within a range of +/- 15º.

A non-drip valve (A) is fitted to avoid chemical spillage the sections are

shut off.

The nozzle type (B) are a hollow cone nozzle, also known as ATR. They

are colour-coded and the working range is 5-15 bar.

This type of nozzle can also be used with hydro-pneumatic equipment.

ATTENTION! It is not advisable to exceed 15 bar with ATR

nozzles as the droplets would be too small, and the liquid will

either evaporate under hot conditions or be lost due to wind

drift.

Cleaning the tank and liquid system

1. Dilute remaining spray liquid in the tank with at least 10 parts of water and spray the liquid out in the crop/

orchard just sprayed.

2. Select and use the appropriate protective clothing. Select detergent suitable for cleaning and suitable

deactivating agents if necessary.

3. Rinse and clean mistblower and tractor externally. Use detergent if necessary.

4. Remove tank and suction filters and clean. Be careful not to damage the mesh. Replace suction filter top. Replace

filters when the sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Don’t forget the tank roof. Rinse and operate all components

and any equipment that have been in contact with the chemical. Before opening the distribution valves and

spraying the liquid out, decide whether this should be done in the field again or on the soakaway.

6. After spraying the liquid out, stop the pump and fill at least 1/5 of the tank with clean water. Note that some

chemicals require the tank to be completely filled. Add appropriate detergent and/or deactivating agent, e.g.

washing soda or Triple ammonia.

7. Start the pump and operate all controls enabling the liquid to come into contact with all the components. Leave

the distribution valves until last. Some detergents and deactivating agents work best if left in the tank for a short

period. Check the label.

8. Drain the tank and let the pump run dry. Rinse inside of the tank, again letting the pump run dry.

9. Stop the pump. If the pesticides used have a tendency to block nozzles and filters, remove and clean them

immediately.

10. Replace all the filters and nozzles and store the mistblower. If, from previous experiences, it is noted that the

solvents in the pesticide are particularly aggressive, store the sprayer with the tank lid open.

ATTENTION! It is advisable to increase the forward speed (double, if possible) and reduce the pressure to 1.5 bar

(20 psi) when spraying diluted remaining liquid in the field just sprayed.

ATTENTION! If a cleaning procedure is given on the chemical label, follow it closely.

ATTENTION! If the sprayer is cleaned with a high pressure cleaner, lubrication of the entire machine is

recommended.

A

B

Summary of Contents for ZENIT 400

Page 2: ......

Page 4: ......

Page 10: ...6...

Page 117: ......

Page 118: ...ILEMO HARDI S A U Poligono Industrial El Segre 712 713 25080 Lleida SPAIN...