9

65mm FlexC

™

Collet System Style DL

Instructions B-152C

Hardinge Inc. One Hardinge Drive, Elmira, New York U.S.A.

1

4902-

1

507 800.843.8801 (Canada 800.468.5946) www.shophardinge.com

Par

t No

. BC -0009500-0152

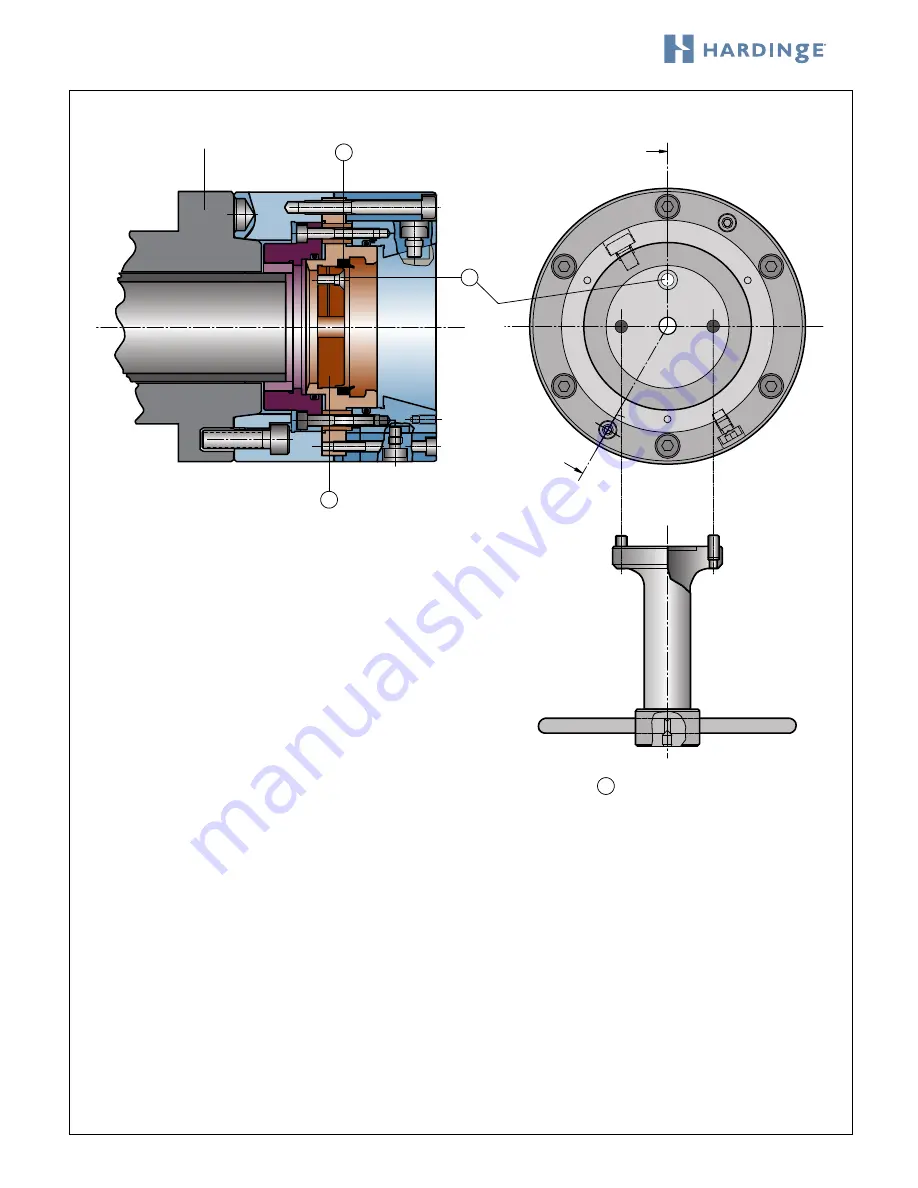

Spindle

B

A

SECTION A-B

17

19

6

10 PART STOP WRENCH

Removing or Changing the Work Stop

Follow the previous instructions to remove the collet head

before changing the work stop. The collet head must be in

the unclamp position. Reach in and remove the seal #17

and set it aside.

Turn the locking screw #19 counterclockwise to loosen the

threads to allow the removal of the work stop #6. It is not

necessary to remove the locking screw.

A work stop wrench #10 is supplied with the spindle

mount assembly to remove the work stop. Align and insert

the pins of the wrench into the holes in the face of the

work stop. Turn the wrench counterclockwise to unscrew

the work stop. If you feel resistance you must go back and

loosen the locking screw #19.

The work stop has an M12 thread in the center to secure a custom work stop for required workpiece applications.

To reassemble, simply follow the same instructions in reverse order. Insert the work stop with the two pin holes facing out.

Tighten the locking screw by hand to ensure that there will be no movement in the dead-length

®

work stop. Remember to

replace the seal #17 before inserting your collet head. Failure to use the seal may cause malfunction of the collet system.