Any-Weigh™ Series Floor Scales

25

Step 15.

Run the load sensor cable through the

channel to the summing box. Bundle up

any excess cable and store it in the chan-

nel. DO NOT CUT THE CABLE TO

MAKE IT FIT BETTER. If you cut the

cable, you will not get correct readings

from the load sensors.

Step 16.

Reconnect the cable wires according to the

color code in Step 3 to the correct load

sensor connector.

OPTIONAL PIT

FRAMES

About Pit Frames

The pit frame optional accessory is a one-piece

welded unit with no additional welding required.

There are 3 different type frames with many sizes for

each type. This accessory is designed for in-floor or

'flush' applications. In general, a hole is cut in the con-

crete, the pit-frame accessory is installed in the hole,

then concrete is poured around and under the frame.

Once cured, the scale platform is set into the frame

and installation can be completed.

Standard duty frames are available in mild steel or

stainless steel for all the floor scale sizes. The con-

crete work and frame setting is usually done by a con-

tractor, with a scale technician completing the project

by setting and installing the scale.

•

A soil bearing pressure of at least 1,000 lbs

per square foot is required. The corner pier

should be designed to support at least two

thirds of the total capacity of the scale.

•

A 3/4” diameter conduit for the scale inter-

face cable is recommended. The pit frame is

arranged with a 1 1/8” diameter hole for a

cable exit. Locate the conduit to match the

hole location.

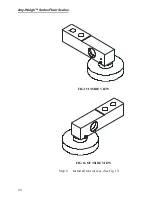

Step 1.

Place the pit frame in the approximate

position it will occupy on the floor. (See

Fig. 21)

Summary of Contents for Any-Weigh

Page 4: ......

Page 8: ...Any Weigh Series Floor Scales II ...

Page 52: ...Any Weigh Series Floor Scales ...