Any-Weigh™ Series Floor Scales

28

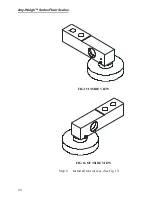

FIG. 23 DRAIN INSTALLATION DIMENSIONS

Step 4.

The hole will have to be deep enough to

accommodate the pit coping, plus the

thickness of the pit floor. (See Fig. 24)

FIG. 24 EXCAVATED PIT AND SUPPORT FOR

THE PIT FRAME

Step 5.

Set the frame in the hole supported at

about the correct height.

Step 6.

Set two 2 x 4 's on edge (longer than the

width of the hole) across the opening. (See

Fig. 7)

Step 7.

Use soft wire and make 2 loops by twist-

ing wire around each 2 x 4 and the frame

Step 8.

With the frame supported by the wire and

2 x 4's, use a spirit level to set the frame

flush with the surrounding floor, level the

frame to within 1/8”, corner to corner, side

to side and diagonally, and at the correct

height by twisting or untwisting the wires.

(See Fig. 7)

Step 9.

Concrete specifications:

•

At least 6” thickness of concrete is required

for pit floor in Non-Hostile applications.

11” (279.4mm)

Drain

4” (101.6mm)

Frame Assembly

2 x 4

Wire

Pit

Summary of Contents for Any-Weigh

Page 4: ......

Page 8: ...Any Weigh Series Floor Scales II ...

Page 52: ...Any Weigh Series Floor Scales ...