HARDY MANUFACTURING CO., INC (MODEL H25) PAGE 28

Section VII

7-5

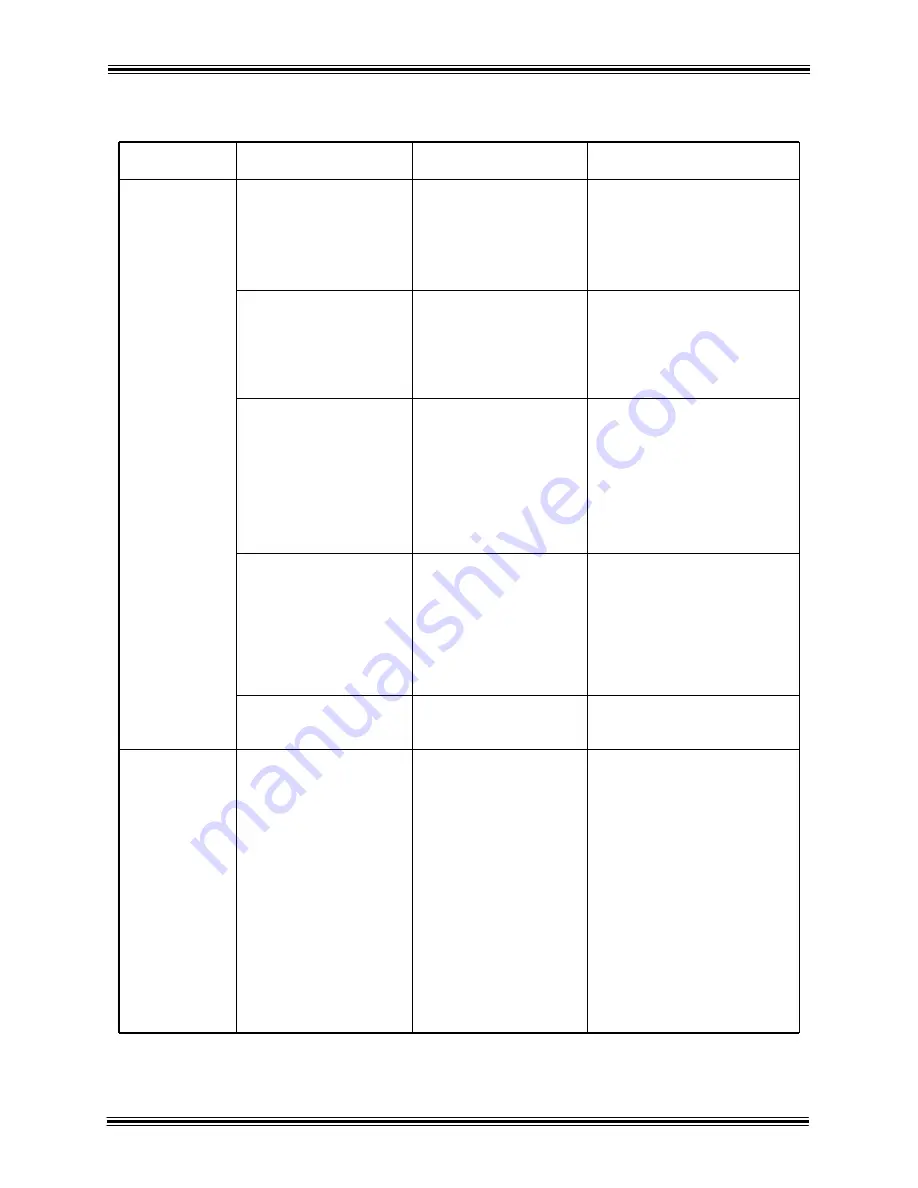

Trouble Shooting Guide H25

NO HEAT

Main power

supply and

ground fault

interrupter

receptacle “OK”

Water

temperature is

“COLD”

Aquastat

1 Defective Aquastat

1 Place a jumper wire across

terminal #4  on the

terminal strip. If blower and

Damper solenoid operates,

replace aquastat

Damper Solenoid

1 Defective damper

solenoid

1 When bypassing aquastat if

solenoid does not lift the lid

off the intake to the forced

air draft blower, replace the

solenoid.

Forced Air Draft Blower

Motor

Defective blower motor

1 Defective electrical

wiring

2 Air passage stoppage

3 Blower wheel clogged

1 Make sure all connections

are secure.

2 Clear air passages in

cleanout and damper blower

outlets

3 Clear blower wheel of any

lint, ashes or creosote build

up.

Ash Bin

1 Ash buildup in ash bin 1 Clean out ash bin. Ash bin

should be cleaned out each

week. Ash build up on grates

can cause grates to warp. If

grates warp they can be

turned over and allowed to

straighten.

Heater Stack

1 Ash and Creosote

Buildup

1 Clean heater stack of any ash

and creosote build up.

Excessive Wood

Usage

Firebox

1 Open

2 Defective door seals

3 Damper lid not closing

properly

4 T & P valve leaking

1 Close all doors and make

sure they are securely

fastened.

2 If the seal is bad it will need

replacing. Call your local

Hardy dealer to request rope

and silicone. See owners

manual, (heater operation

section) for replacing door

seals.

3 Remove any obstructions

causing lid not to close

properly.

4 If leaking, replace.

COMPLAINT

AREA OF TROUBLE

POSSIBLE CAUSES

CORRECTIVE ACTION

Summary of Contents for H25

Page 2: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 6: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 10: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 40: ...HARDY MANUFACTURING CO INC MODEL H25 PAGE 30 THIS PAGE INTENTIONALLY LEFT BLANK ...

Page 41: ...HARDY MANUFACTURING CO INC MODEL H25 PAGE 31 ...