IV

HARGASSNER Heating technology for

Biomass

A 4952 Weng OÖ Tel.: +43/7723/5274-0 Fax: +43/7723/5274-5 office@hargassner.at

53

Cleaning, Maintenance

2

Cleaning and maintenance

Boiler monitoring and cleaning intervals are based on the operation hours

and fuel quality.

Observe country-specific regulations and the inspection and sweeping inter

-

vals dictated by these.

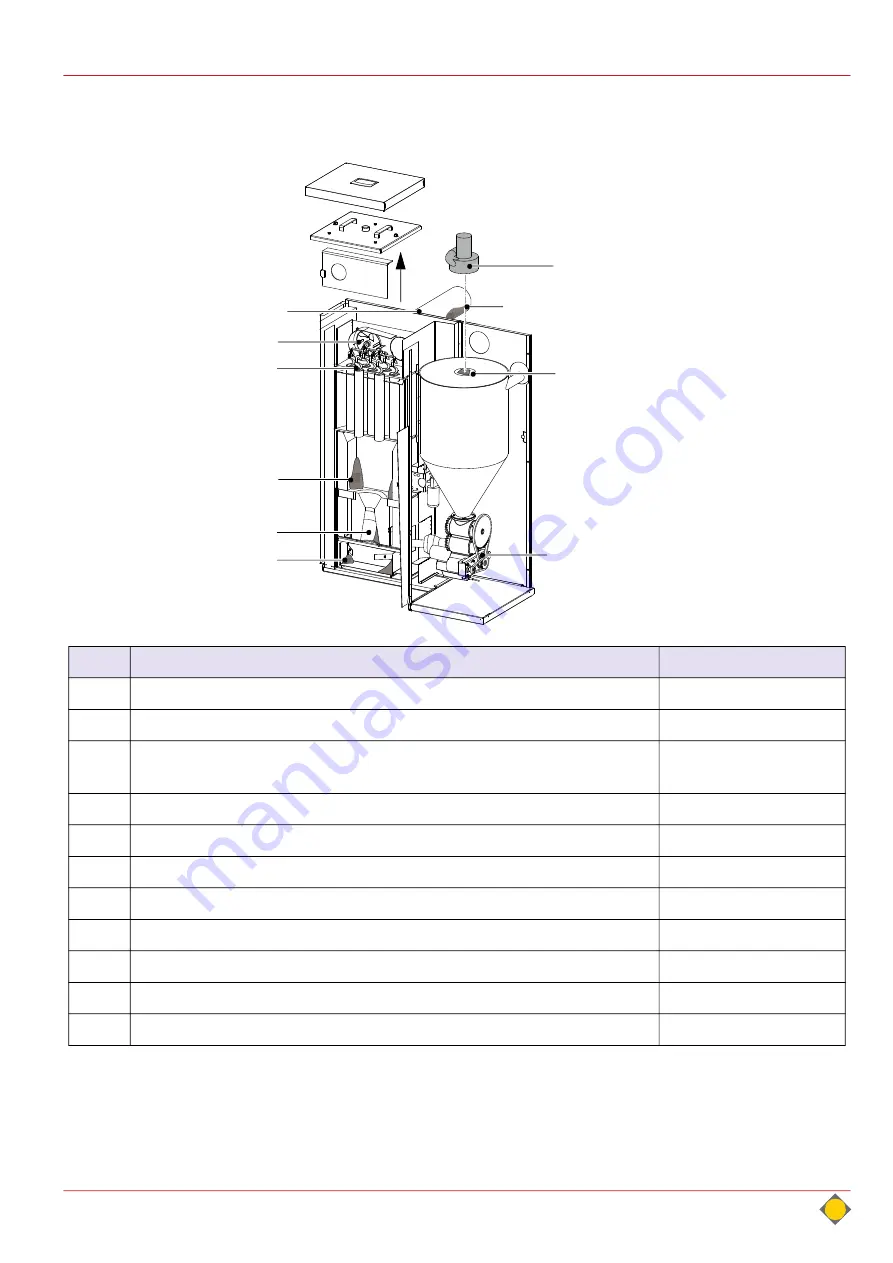

Pos. Tasks of maintenance

Interval

( a = annually

a

)

a. At least once annually, at the latest after 4000 full-load hrs, 8000 partial-load hrs or after a message has appeared on the

control panel

1

Tap off the turbulators and clean the turbulator space

1x a

2

Clean flue pipe

2x a

3

Clean post-combustion chamber with poker

(visual check via inspection glass)

1x a

(as required)

4

Clean combustion chamber with poker

1 x a (as required)

5

Remove ash box and clean out the ash under the grate

1x a

6

Dismount exhaust fan and clean housing and impeller

1x a

7

Grease stoker chain and check chain tension

1x a

8

Clean pellet vacuum turbine

1x a

9

Clean the pellet vacuum turbine filter.

1x a

10

Disconnect, remove and clean the lambda sensor

1x a

11

Ash box emptying

as required

1

2

3

4

5

6

7

8

9

10

Summary of Contents for Classic 12

Page 64: ......