CLUTCH

USER MANUAL

21

EN

1. TRACEABILITY &

MARKINGS

See section 1.

2. FIELD OF

APPLICATION

These instructions explain the correct use of your

equipment. Only certain techniques and uses are

described. The warning symbols inform you of

some potential dangers related to the use of your

equipment, but it is impossible to describe them

all. Check cmcpro.com for updates and additional

information. You are responsible for heeding each

warning and using your equipment correctly. Any

misuse of this equipment will create additional

dangers. Contact CMC if you have any questions or

difficultyunderstandingtheseinstructions.

Standards

Descent Control Device, Belay Device, Pulley per

NFPA 1983 (2017 ED)

Descent Control Device per ANSI/ASSE Z359.4

- 2013

Responsibility

Before using this device, you must:

• Read and understand these user instructions

and warnings.

•

Getspecifictraininginitsproperuse.

• Familiarize yourself with its capabilities and

limitations.

• Understand and accept the risks involved.

• Have a rescue plan in place to deal with any

emergencies that could arise during use of

the device.

•

Bemedicallyfitforactivitiesatheight.Becapable

to control your own security and any possible

emergency situations.

Specifictrainingintheactivitiesdefinedinthefield

of application is essential before use. This device

must only be used by competent and responsible

persons, or those placed under the direct and visual

control of a competent and responsible person.

Gaining an adequate expertise in appropriate

techniques and methods of protection is your own

responsibility. You personally assume all risks and

responsibilities for all damage, injury or death,

which may occur during or following incorrect use

of this device in any manner whatsoever. If you

are not able, or not in a position to assume this

responsibility or to take this risk, do not use this

equipment.

This device must not be loaded beyond its strength

rating, nor be used for any purpose other than that

for which it is designed.

This equipment does not need to be a personal

issue item.

WARNING: Activities involving the use

of this device are inherently dangerous.

You are responsible for your own actions,

decisions and safety.

WARNING: Inert suspension in a harness

can result in serious injury or death.

3. NOMENCLATURE

1. Moving Side Plate

2. Side Plate Release Latch

3. Tension Rope Guide

4. Sheave

5. Sheave Swing Arm

6. Friction Shoe

7. Becket

8. Control Handle

9. Chassis

10. Attachment Eye

11. Side Plate Lockout Screw Hole

12. Side Plate Lockout Screw

13. Handle Positions

A. Stop

B. Standby

C. Release (Range)

D. Antipanic

14. Rope Path

A. Tension Side (Load/Anchor)

B. Braking Side

C. Brake Hand

4. INSPECTION

POINTS TO VERIFY

Inspection Points to Verify

The CLUTCH is controlled through CMC’s ISO

9001 approved quality processes, however it should

be thoroughly inspected before being placed in

service. The CLUTCH is also a robust product but

should still be inspected after each use to ensure

that damage did not occur. The CLUTCH does not

have a known time-limit to the usable life, however

CMC recommends a detailed inspection by a

competent person at least once every 12 months

(depending on current regulations in your country,

and your conditions of use). Record the date of the

inspection and the results in the equipment log or

on inspection forms that can be found on cmcpro.

com/ppe-inspection/.

Before Each Use

• Perform a function test of the device by loading

it properly on the rope and ensuring that it

holds a test load without slipping on the rope as

described in Section 8 of this Manual.

• Verify the presence and legibility of the product

markings.

• Verify that the device has no cracks, deformation,

excessive wear, corrosion, etc.

• Check for the presence of dirt or foreign objects

thatcanaffectorpreventnormaloperation(e.g.

grit, sand, pebbles, etc.).

• Move the Control Handle through its range

of motion.

• Move the Control Handle to the Standby

position and check that the Sheave Swing Arm

moves freely.

• Check that the Sheave is in good condition and

freely rotates only anti-clockwise.

• Check the Sheave for wear; when the wear indi-

cators are no longer visible, the holding capacity

of the device may be compromised. Refer to the

following page for details on the wear indicators.

Take extra precaution and consider retirement

of the device.

• Check the Side Plate for deformation or

excessive play; if the Side Plate can pass over

the Chassis (see diagram), discontinue use of

the CLUTCH.

During Each Use

Make sure that all pieces of equipment in the

system are correctly positioned with respect to each

other. Regularly monitor the condition of the device

and its connections to other equipment in the

system. Do not allow anything to interfere with the

operation of the device or its components (Sheave,

Control Handle, etc.). Keep foreign objects out of

the device. To reduce the risk of a free fall keep

all slack out of the rope between the device and

the load/anchor.

WARNING: performance can vary depend

-

ing on the state of the rope (wear, mud,

moisture, ice, etc).

Retirement

This equipment has an unlimited lifetime, how-

ever usage and exceptional events may require

retirement. Destroy retired equipment to prevent

further use.

A device must be retired when:

• It has been subjected to a major fall (or load).

• It fails to pass inspection.

• It fails to hold a load without slipping on the rope.

• You have any doubt as to its condition or

reliability.

• You do not know its full usage history.

• When it becomes obsolete due to changes in leg-

islation, standards, technique or incompatibility

with other equipment, etc.

WARNING: An exceptional event can lead

you to retire a device after only one use,

depending on the type and intensity of

usage and the environment of usage (harsh

environments, marine environment, sharp

edges, extreme temperatures, chemical

products, etc.)

Carrying, Maintenance, Storage &

Transport

Clean and dry this equipment after each use to

remove any dust, debris and moisture. Use clean

watertowashoffanydirtordebris.Donotusea

pressure washer to clean the device. If device gets

wet, allow the device to air dry at temperatures

between 10° C (50° F) and 30° C (86° F), keep

away from direct heat. During use, carrying, storage

and transport, keep the equipment away from acids,

alkalis, rust and strong chemicals. Do not expose

theequipmenttoflameorhightemperatures.Store

in a cool, dry location. Do not store where the

equipment may be exposed to moist air, particularly

where dissimilar metals are stored together. Ensure

that the equipment is protected from external impact

and keep out of direct sunlight.

Repairs

All repair work shall be performed by the manu-

facturer.Allotherworkormodificationsvoidthe

warranty and releases CMC from all liability and

responsibility as the manufacturer.

5. COMPATIBILITY

Verification

Verify that this device is compatible with the other

elements of the system in your application (compat-

ible = good functional interaction).

WARNING: Danger may arise and function

-

ality may be compromised by combining

other items of equipment in conjunction

with the CLUTCH during use. The user as

-

sumes all responsibility for any non-stan

-

dard use of the device or the components

being used with the device.

NFPA 1983 (2017 ED) “GENERAL USE”

Descent Control Device / Belay Device

/ Pulley

• CMC™ Static-Pro LifeLine 12.5 mm P/N 28120X

General Use Life Safety Rope

• Teufelberger KM III 13 mm P/N K0X160 General

Use Life Safety Rope

ANSI/ASSE Z359.4-2013 Descent Control

Device

• Teufelberger KM III 13 mm P/N K0X160 60-

141kg MAX 200m

Ropes

Use only the recommended diameters and types of

synthetic rope. The use of any other diameter/type

of rope changes the performance of the device,

especiallythebrakingeffectiveness.

WARNING: The stated diameter of ropes on

the market may have a tolerance of up to

+/- 0.2 mm. Certain ropes may be slippery:

new ropes, small diameter ropes, wet or

frozen ropes. Braking effectiveness and

ease of giving slack can vary depending on

the diameter, construction, wear and tear,

and surface treatment of the rope, as well

as other variables such as frozen, muddy,

wet, dirty ropes, etc. At each use, the user

must familiarize him or herself with the

braking effect of the device on the rope and

22

MANUAL TEXT

Summary of Contents for CMC CLUTCH

Page 4: ...CLUTCH USER MANUAL 4 1 TRACEABILITY MARKINGS H K A C B F G D E L I J...

Page 6: ...CLUTCH USER MANUAL 6 3 NOMENCLATURE 11 2 6 13 14...

Page 8: ...CLUTCH USER MANUAL 8 6 WORKING PRINCIPLE Lower Descent Stop Antipanic Stop Lock Haul...

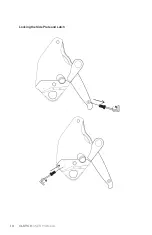

Page 10: ...CLUTCH USER MANUAL 10 Locking the Side Plate and Latch...

Page 12: ...CLUTCH USER MANUAL 12 9 SECURING TIE OFF X m s max...

Page 13: ...CLUTCH USER MANUAL 13 10 PRECAUTIONS FOR USE X m m X m...

Page 14: ...CLUTCH USER MANUAL 14 X m s max X m s max X m s max...

Page 16: ...CLUTCH USER MANUAL 16 14 RESCUE SYSTEM BELAYING 15 HAULING...

Page 17: ...CLUTCH USER MANUAL 17 16 DESCENT AND LOWERING 17 ASCENDING...

Page 30: ...CLUTCH USER MANUAL 30...

Page 31: ...CLUTCH USER MANUAL 31...