16

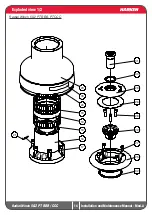

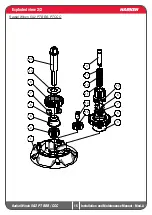

Radial Winch

50.2 PT BBB / CCC

Installation and Maintenance Manual - Mod.A

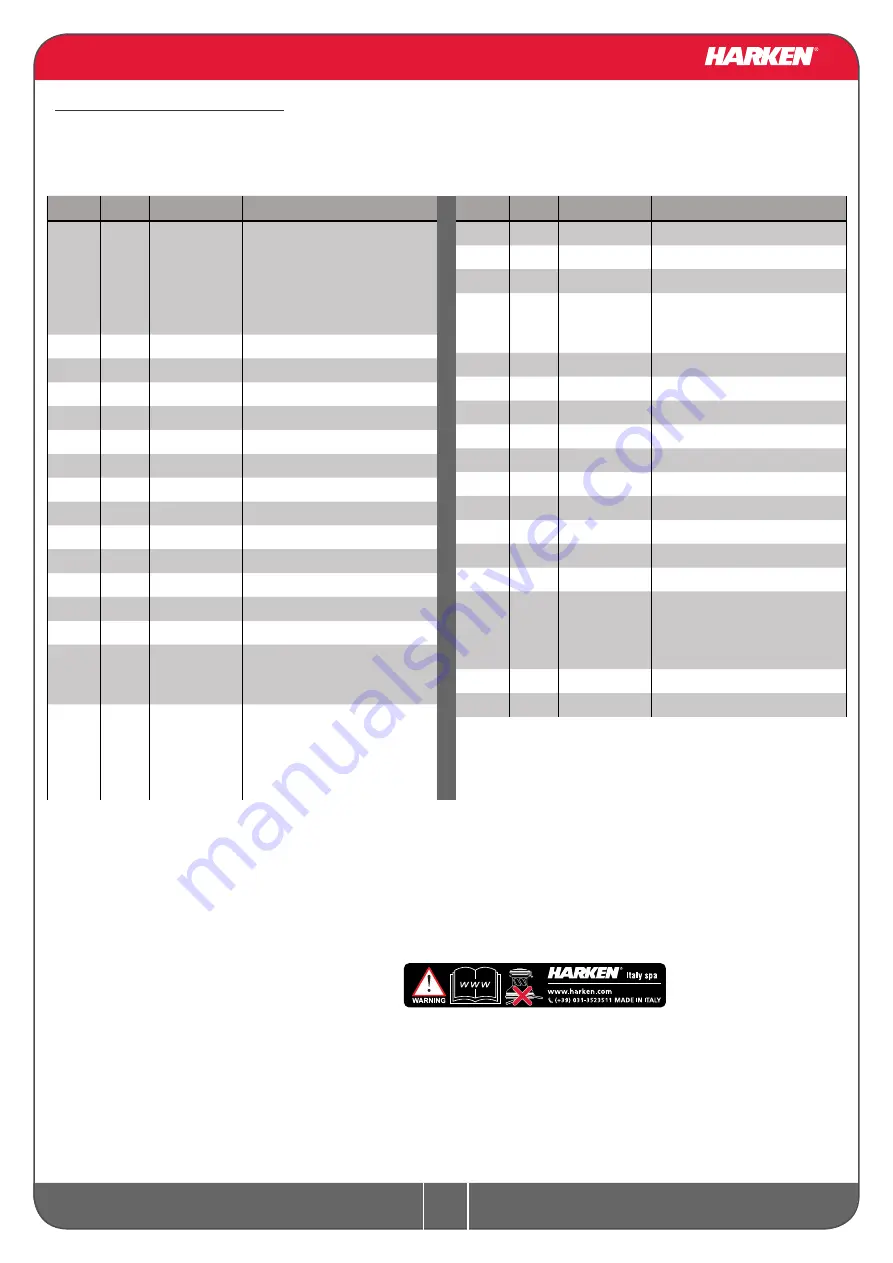

Parts list

Radial Winch 50.2 PTBBB

BBB = all bronze

*Available with service kit; see website www.harken.com

**Winch product sticker

Pos.

Q.ty Code

Description

1

1

1

1

1

1

A96633400

S413350080

S4152300A7

S414890080

S413330085

Assy Base Winch 50

Base W50

Roller Ø6x19

Bushing Ø22xØ25x9.5

Bushing Ø9xØ11x7

Bushing Ø12xØ14x11

2

1

S413020004

Gear Z12

3

1

S416050004

Pin

4

1

S278170002

Washer Ø12.5xØ48x1.5

5

1

S412800041

Gear Z30

6

1

S414260004

Pawls Carrier Ø8xN2

7

6

S000080003

Pawl Ø8*

8

6

S000380001

Pawl Spring Ø8*

9

1

S415590041

Gear Z20

10

1

S415610004

Pinion Z11

11

2

A72821800

Roller Bearing Ø14xØ20x18

12

2

S281340080

Spacer roller bearings

13

1

S413120002

Washer Ø22.5xØ45x1

14

1

S413070004

Pin Ø9xØ12x32.5

15

1

2

A94156000

S414900080

Assy Gear Z11

Gear Z11

Bushing Ø12xØ14x8

16

1

1

1

1

A94134800

S414900080

S413330085

S4133200B3

Assy Housing Winch 50

Housing Winch 50

Bushing Ø12xØ14x8

Bushing Ø12xØ14x11

Bushing for support

Pos.

Q.ty Code

Description

17

5

M0643203

Screw M8x20 UNI5931

18

2

A74135100

Bearing Ø85xØ97x26

19

1

S413520080

Spacer

20

1

1

A94152000

S415200002

Assy Central Shaft W50

Washer Ø17.2xØ32x1.5

Central shaft W50 PT

21

Winch Serial Number Sticker

22

1

S4151400A0

Socket Support PT

23

1

S688140043

Drum W50 B

24

1

S281690097

Red line

25

1

S688020043

Plain Top W50 PT BBB

26

1

S678730082

Washer Ø57.5xØ93x1.5

27

4

M0603703

Screw M6x12 UNI 5931

28

3

M0600903

Screw M6x20 UNI5931

29

1

S688100043

Cover W50 PT BBB

30

1

S415220080

PT spacer

31

1

1

1

A94136400

S415130085

M0614303

Assy Socket W20-80

Socket Handle W20/80

Washer Ø7.7xØ25x5.8

Screw M8x20 UNI 6109

32

50

M0619580

Ball 3/16"

33

Winch Product Sticker**