MKIV Ocean Unit 3

24

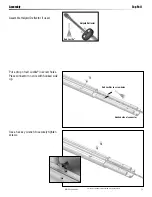

Commissioning Pendant/Halyard: Restrainer/Tension

Halyard Deflector/Halyard Restrainer

To prevent wraps, jib halyard must pull slightly to rear. On most boats,

halyard lead angle is acceptable if halyard swivel is raised to top of foil.

On some boats halyard sheaves are located too close to headstay and

a Halyard Deflector or Halyard Restrainer must be used.

Halyard restrainers should be used only when required by masthead

geometry. Restrainers tend to limit sail luff length and may cause

problems if not installed properly.

If your boat needs a Halyard Deflector, use Part No. 7304 or a Halyard

Restrainer, use Harken Part No. 945.

Restrainer should be mounted as high as possible on face of mast.

Position restrainer so that foils will not hit it when under load.

The restrainer should deflect halyard as little as possible or you may

experience difficulty in tensioning sail luff, friction when furling, and

possible damage to foils. To decrease deflection angles, shorten sail luff.

Tip: Boats used in charter service should have a halyard restrainer,

regardless of masthead geometry.

Halyard Tension

The jib halyard should be firm, but not too tight.

Tip: The luff foil system supports sail along its length so halyard

tension is used only to shape sails, not to support them. Use enough

halyard tension to remove some wrinkles along luff of sail. Do not

tension halyard enough to cause vertical wrinkles in luff of sail.

Tension to adjust position of draft in sail to suit sailing conditions.

Halyard should be firm but not tight. If in doubt, release halyard

tension. To protect sail, ease halyard when boat is not in use.

Pendants

If the your sail luff is not long enough to position halyard swivel high

enough to create an 8–10° angle as shown, you must add a pendant.

Pendants should be made of plastic-coated wire and be permanently

attached so sail height will be correct. Adjustable-length pendants

are not acceptable, as they might not be adjusted correctly during a

sail change.

1. Raise sail so sail is near the top of the foil.

Do not attach tack shackle.

2. Position halyard swivel correctly near top of headstay.

3. Secure halyard.

4. Tie a piece of rope to sail tack.

5. Lead line through tack shackle on furling drum.

6. Tension sail.

7. Measure distance from tack shackle to sail tack and permanently

attach pendant of this length to head of sail.

8. Repeat procedure for every jib in your sail inventory.

Halyard Deflector

Halyard Restrainer