22

CLR Mooring Winch

Installation and Maintenance Manual - Mod.A

Installation

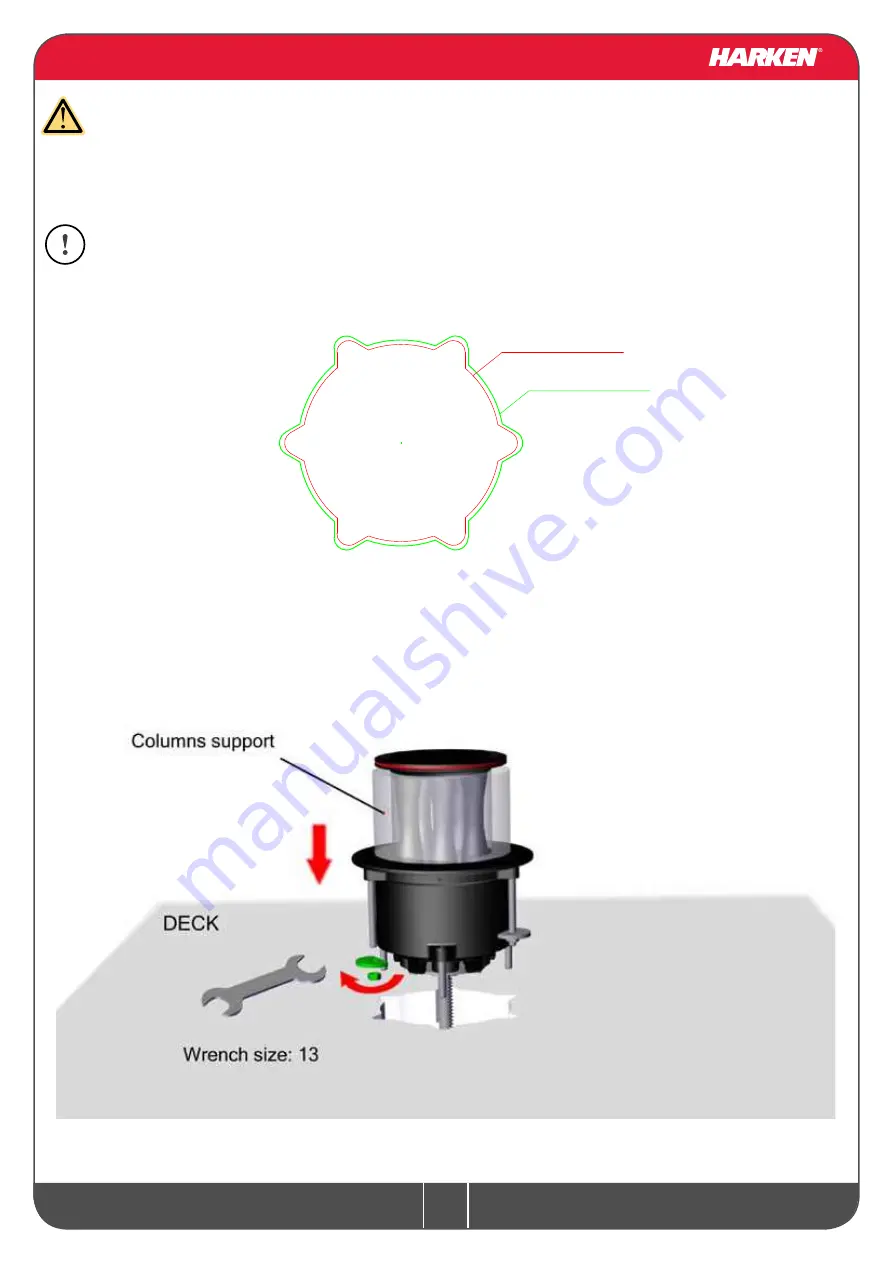

Sealing edge

Deck cut out

6. Unscrew the nuts of the installation screws and the remove the deck washers

(deck washers allow to close the installation screws from the underdeck side).

WARNING!

The mounting bolts must be isolated with anti-corrosive lubricants.

It is mandatory to prevent any direct contact between the aluminium plates from other conductive

materials such as carbon fiber (deck or hull); in that case a fiberglass lamination is required to avoid

any galvanic corrosion.

NOTE!

Installation bolts are provided by Harken: Winches CLR are equipped with M8x90 A4 stainless steel

screws and deck washers.